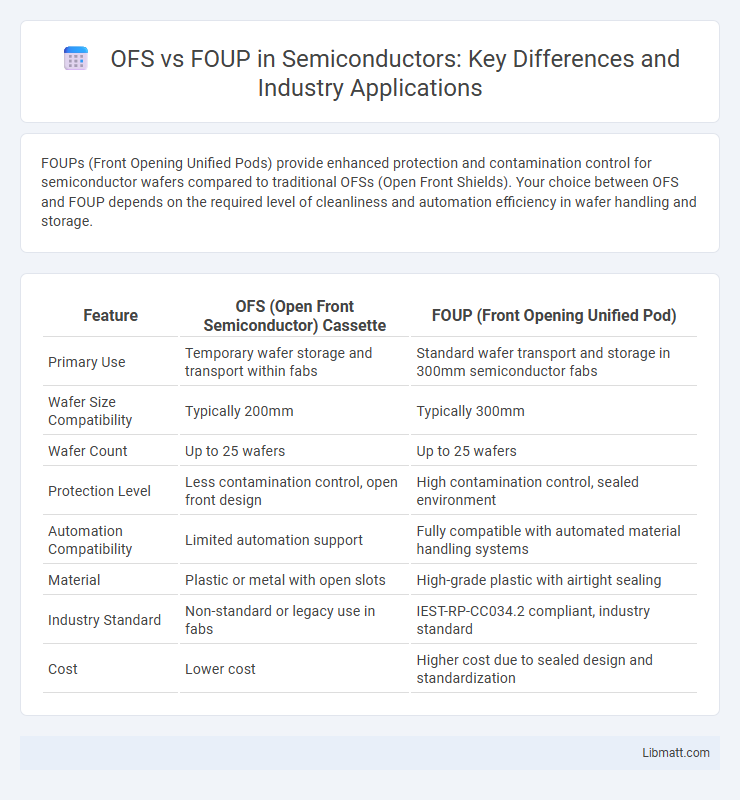

FOUPs (Front Opening Unified Pods) provide enhanced protection and contamination control for semiconductor wafers compared to traditional OFSs (Open Front Shields). Your choice between OFS and FOUP depends on the required level of cleanliness and automation efficiency in wafer handling and storage.

Table of Comparison

| Feature | OFS (Open Front Semiconductor) Cassette | FOUP (Front Opening Unified Pod) |

|---|---|---|

| Primary Use | Temporary wafer storage and transport within fabs | Standard wafer transport and storage in 300mm semiconductor fabs |

| Wafer Size Compatibility | Typically 200mm | Typically 300mm |

| Wafer Count | Up to 25 wafers | Up to 25 wafers |

| Protection Level | Less contamination control, open front design | High contamination control, sealed environment |

| Automation Compatibility | Limited automation support | Fully compatible with automated material handling systems |

| Material | Plastic or metal with open slots | High-grade plastic with airtight sealing |

| Industry Standard | Non-standard or legacy use in fabs | IEST-RP-CC034.2 compliant, industry standard |

| Cost | Lower cost | Higher cost due to sealed design and standardization |

Introduction to OFS and FOUP

OFS (Open Front Surface) and FOUP (Front-Opening Unified Pod) are critical components in semiconductor manufacturing for wafer handling and protection, designed to optimize yield and minimize contamination. FOUPs are specialized containers that secure wafers during automated processes, maintaining a cleanroom environment, while OFS refers to the open-front design often used for manual wafer handling or inspection stages. Understanding the distinctions between OFS and FOUP helps you select the appropriate wafer cassette system for your fabrication workflow, ensuring efficiency and wafer integrity.

Key Differences Between OFS and FOUP

OFS (Open Front Seal) and FOUP (Front Opening Unified Pod) differ primarily in their design and sealing mechanisms; OFS uses a simpler open-front seal facilitating easier wafer access, while FOUP employs a sealed front opening to provide enhanced contamination control. FOUPs are widely used in semiconductor manufacturing for automated wafer handling, offering superior protection against particulate and environmental exposure compared to OFS. The key difference lies in FOUP's standardized interface compatible with automated tools, whereas OFS is typically used in less automated or manual processing stages.

Structure and Design Comparison

OFS (Open Front Side) containers feature an open-front design allowing quicker wafer access and improved handling during processing, with fewer mechanical parts reducing failure risks, whereas FOUPs (Front-Opening Unified Pods) have a sealed, front-opening door ensuring superior contamination control in highly sensitive environments. FOUPs incorporate advanced sealing mechanisms and robotic interface compatibility, promoting precise wafer alignment and protection during transport, while OFS containers typically offer simpler structures optimized for faster loading and unloading. The design trade-off between OFS and FOUP highlights the balance between contamination prevention and operational efficiency in semiconductor wafer handling systems.

Material Handling Capabilities

OFS (Open Front Shelf) systems offer flexible material handling with easy access to semiconductor wafers, enabling faster loading and unloading processes. FOUP (Front Opening Unified Pod) containers provide enhanced protection and contamination control with automated handling compatibility in fabs, supporting high-throughput semiconductor manufacturing. Both systems optimize wafer transport, but FOUP's sealed design and integration with robotic systems deliver superior environmental isolation during material handling.

Cleanliness and Contamination Control

FOUPs (Front Opening Unified Pods) provide superior cleanliness and contamination control compared to OFSs (Open Front SMIF Standard). FOUPs are fully enclosed systems that minimize particle intrusion and maintain a controlled environment for semiconductor wafers, reducing the risk of contamination during transport and storage. Their sealed design incorporates filtered air circulation, which effectively protects sensitive wafers from airborne particles and other contaminants.

Efficiency in Semiconductor Manufacturing

OFS (Open Front Standard) and FOUP (Front Opening Unified Pod) both serve as essential wafer carriers in semiconductor manufacturing, but FOUPs are more efficient due to their airtight design that minimizes contamination and maintains a controlled environment for wafers. FOUPs support automated handling systems, reducing manual intervention and increasing throughput, which is critical for maintaining the high precision and yield in semiconductor fabrication. Your production lines benefit significantly from FOUPs' compatibility with advanced automation technologies, streamlining wafer transfers and enhancing overall manufacturing efficiency.

Cost Analysis: OFS vs FOUP

Cost analysis reveals that OFS (Open Front Ship) systems generally incur lower upfront expenses compared to FOUP (Front Opening Unified Pod) systems due to simpler construction and less complex sealing mechanisms. However, FOUPs offer enhanced wafer protection and contamination control, potentially reducing long-term operational costs linked to yield losses and equipment downtime. Your choice should weigh initial savings against reliability and maintenance expenses over the device's lifecycle.

Industry Applications and Use Cases

OFS (Optical Fiber Splicing) and FOUP (Front Opening Unified Pod) serve distinct roles in semiconductor and telecommunications industries. OFS is essential in telecom network installations, data centers, and fiber optic cable repairs where precise fiber alignment enhances signal integrity. FOUP is widely used in semiconductor fabrication for securely transporting silicon wafers in cleanroom environments, ensuring contamination-free manufacturing processes.

Challenges and Limitations

OFS (Optical Fiber Storage) and FOUP (Front Opening Unified Pod) each face specific challenges in semiconductor manufacturing environments. OFS systems struggle with scalability and contamination control due to open access designs, whereas FOUPs offer superior particle containment but are limited by higher costs and compatibility issues with older equipment. Your choice must balance the critical need for cleanliness and system integration with budget constraints and production scale.

Future Trends in Wafer Handling Technology

Future trends in wafer handling technology emphasize increased automation and precision, with FOUP (Front Opening Unified Pod) systems dominating due to their enhanced contamination control and compatibility with advanced lithography processes. OFS (Open Front Side) systems are gradually being phased out as semiconductor manufacturing demands stricter particle control and integration with Industry 4.0 smart factories. Emerging developments include robotic wafer transfer, real-time monitoring sensors, and AI-driven predictive maintenance to optimize throughput and yield in 300mm and upcoming 450mm wafer fabs.

OFS vs FOUP Infographic

libmatt.com

libmatt.com