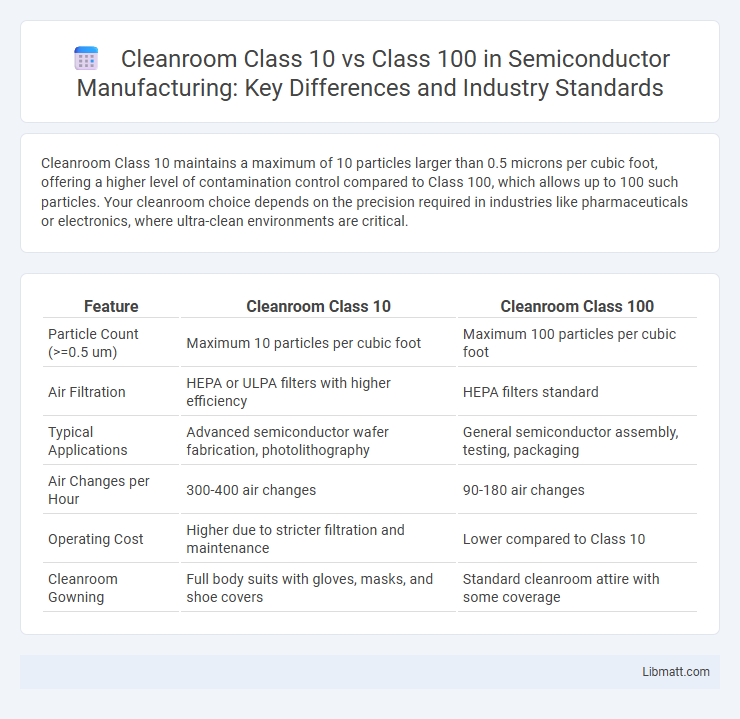

Cleanroom Class 10 maintains a maximum of 10 particles larger than 0.5 microns per cubic foot, offering a higher level of contamination control compared to Class 100, which allows up to 100 such particles. Your cleanroom choice depends on the precision required in industries like pharmaceuticals or electronics, where ultra-clean environments are critical.

Table of Comparison

| Feature | Cleanroom Class 10 | Cleanroom Class 100 |

|---|---|---|

| Particle Count (>=0.5 um) | Maximum 10 particles per cubic foot | Maximum 100 particles per cubic foot |

| Air Filtration | HEPA or ULPA filters with higher efficiency | HEPA filters standard |

| Typical Applications | Advanced semiconductor wafer fabrication, photolithography | General semiconductor assembly, testing, packaging |

| Air Changes per Hour | 300-400 air changes | 90-180 air changes |

| Operating Cost | Higher due to stricter filtration and maintenance | Lower compared to Class 10 |

| Cleanroom Gowning | Full body suits with gloves, masks, and shoe covers | Standard cleanroom attire with some coverage |

Understanding Cleanroom Classifications: An Overview

Cleanroom classifications, such as Class 10 and Class 100, are defined by the number of airborne particles measuring 0.5 microns or larger permitted per cubic foot of air; Class 10 allows a maximum of 10 particles, while Class 100 permits up to 100 particles. These standards are established by the Federal Standard 209E, where lower class numbers indicate cleaner environments essential for industries like semiconductor manufacturing and pharmaceutical production. Understanding the strict particle count and airflow requirements ensures proper contamination control and compliance with regulatory guidelines.

Key Differences Between Class 10 and Class 100 Cleanrooms

Class 10 and Class 100 cleanrooms differ primarily in particle count limits, with Class 10 allowing no more than 10 particles (0.5 microns or larger) per cubic foot of air, compared to Class 100's limit of 100 particles per cubic foot. The stringent particle control in Class 10 cleanrooms necessitates more advanced filtration systems, tighter air flow patterns, and higher maintenance standards. Your choice between these classifications impacts contamination control, operational costs, and suitability for sensitive processes in pharmaceuticals, electronics, or biotechnology.

Particle Count Limits: Class 10 vs Class 100

Cleanroom Class 10 limits airborne particles to a maximum of 10 particles (0.5 microns or larger) per cubic foot, ensuring ultra-clean environments ideal for semiconductor manufacturing and pharmaceutical applications. Class 100 allows up to 100 particles of 0.5 microns or larger per cubic foot, providing less stringent but still highly controlled contamination levels suitable for many electronic and biotech processes. Your choice between Class 10 and Class 100 depends on the specific particle count limits required for your sensitive production or research needs.

Industry Applications for Class 10 and Class 100 Cleanrooms

Class 10 cleanrooms maintain extremely low particle counts, making them ideal for semiconductor manufacturing, aerospace engineering, and pharmaceutical production where contamination control is critical. Class 100 cleanrooms support industries such as biotechnology, medical device assembly, and electronics manufacturing that require high cleanliness but allow for slightly higher particle tolerances. Your choice between Class 10 and Class 100 depends on the specific contamination sensitivity and regulatory requirements of your industry.

Design Considerations for Each Cleanroom Class

Cleanroom Class 10 requires more stringent design considerations, including ultra-high-efficiency particulate air (HEPA) filtration and tighter air change rates to maintain fewer than 10 particles per cubic foot. In contrast, Cleanroom Class 100 allows for a slightly less rigorous design with lower air change rates, targeting fewer than 100 particles per cubic foot. Your choice between these classes directly impacts HVAC system specifications, room pressurization, and contamination control protocols.

Cleanroom Filtration and Airflow Requirements

Cleanroom Class 10 requires higher filtration efficiency with HEPA filters capturing 99.97% of particles >=0.3 microns and maintains airflow rates around 90-120 air changes per hour to minimize particulate contamination. In contrast, Class 100 cleanrooms allow slightly lower filtration performance with similar HEPA standards but typically operate at 60-90 air changes per hour, balancing cleanliness with energy consumption. Understanding these filtration and airflow parameters helps you select the appropriate cleanroom environment for your sensitive manufacturing or research needs.

Operational Protocols in Class 10 vs Class 100 Environments

Operational protocols in Cleanroom Class 10 environments demand stricter contamination controls, including more frequent gowning changes and higher air change rates typically exceeding 600 air changes per hour. Class 100 cleanrooms allow relatively relaxed procedures with air exchange rates around 350-400 air changes per hour and less rigorous personnel movement restrictions. Both classes enforce HEPA filtration and particle monitoring, but Class 10 requires enhanced protocol adherence to maintain the maximum allowable particle count of 10 particles per cubic foot versus 100 particles in Class 100 settings.

Cost Implications: Building and Maintaining Each Class

Cleanroom Class 10 environments demand significantly higher initial construction costs due to stringent filtration systems, ultra-low particle counts, and advanced airflow controls, whereas Class 100 cleanrooms are more cost-effective with comparatively less rigorous requirements. Maintenance expenses for Class 10 cleanrooms are substantially elevated, involving frequent validation, specialized cleaning protocols, and higher-grade consumables. Organizations must evaluate budget constraints against operational needs, as Class 10 cleanrooms can incur up to 2-3 times the total lifetime cost of Class 100 facilities.

Cleanroom Validation and Compliance Standards

Cleanroom Class 10 and Class 100 are defined by ISO 14644-1 standards, which specify maximum allowable particle counts per cubic meter to ensure contamination control. Validation of Class 10 cleanrooms requires rigorous testing methods, including airflow visualization, particle counting, and filter integrity assessments, to meet stricter compliance mandates for industries like semiconductor manufacturing and aerospace. Compliance standards for Class 100 cleanrooms focus on maintaining lower particle concentrations with routine monitoring, filtration efficiency verification, and adherence to FDA and ISO regulations for pharmaceutical and medical device environments.

Selecting the Right Cleanroom Class for Your Application

Selecting the right cleanroom class depends on your contamination control requirements, with Class 10 cleanrooms allowing no more than 10 particles (0.5 microns or larger) per cubic foot of air, while Class 100 cleanrooms permit up to 100 particles per cubic foot. Class 10 cleanrooms are essential for highly sensitive processes such as semiconductor manufacturing and pharmaceutical production, where ultra-low particle counts are critical. Understanding your specific industry standards and contamination tolerance helps ensure your cleanroom maintains optimal air quality and product integrity.

Cleanroom Class 10 vs Class 100 Infographic

libmatt.com

libmatt.com