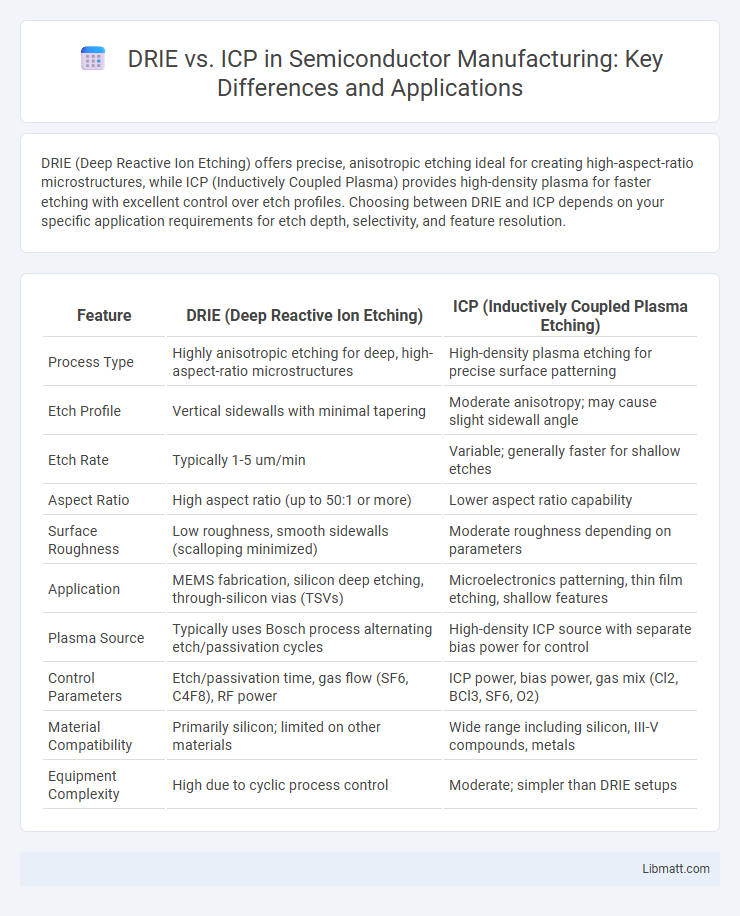

DRIE (Deep Reactive Ion Etching) offers precise, anisotropic etching ideal for creating high-aspect-ratio microstructures, while ICP (Inductively Coupled Plasma) provides high-density plasma for faster etching with excellent control over etch profiles. Choosing between DRIE and ICP depends on your specific application requirements for etch depth, selectivity, and feature resolution.

Table of Comparison

| Feature | DRIE (Deep Reactive Ion Etching) | ICP (Inductively Coupled Plasma Etching) |

|---|---|---|

| Process Type | Highly anisotropic etching for deep, high-aspect-ratio microstructures | High-density plasma etching for precise surface patterning |

| Etch Profile | Vertical sidewalls with minimal tapering | Moderate anisotropy; may cause slight sidewall angle |

| Etch Rate | Typically 1-5 um/min | Variable; generally faster for shallow etches |

| Aspect Ratio | High aspect ratio (up to 50:1 or more) | Lower aspect ratio capability |

| Surface Roughness | Low roughness, smooth sidewalls (scalloping minimized) | Moderate roughness depending on parameters |

| Application | MEMS fabrication, silicon deep etching, through-silicon vias (TSVs) | Microelectronics patterning, thin film etching, shallow features |

| Plasma Source | Typically uses Bosch process alternating etch/passivation cycles | High-density ICP source with separate bias power for control |

| Control Parameters | Etch/passivation time, gas flow (SF6, C4F8), RF power | ICP power, bias power, gas mix (Cl2, BCl3, SF6, O2) |

| Material Compatibility | Primarily silicon; limited on other materials | Wide range including silicon, III-V compounds, metals |

| Equipment Complexity | High due to cyclic process control | Moderate; simpler than DRIE setups |

Introduction to DRIE and ICP

Deep Reactive Ion Etching (DRIE) and Inductively Coupled Plasma (ICP) are advanced plasma etching techniques widely used in microfabrication for precise material removal. DRIE specializes in creating high aspect ratio structures with vertical sidewalls by alternating etching and passivation cycles, making it ideal for MEMS applications. ICP utilizes a high-density plasma generated by inductive coupling, offering high etch rates and excellent control over plasma chemistry, which enhances etch uniformity and profile precision for various semiconductor processes.

Fundamental Principles of DRIE

DRIE (Deep Reactive Ion Etching) utilizes alternating steps of etching and passivation to achieve deep, high-aspect-ratio microstructures with vertical sidewalls, relying on plasma chemistry to selectively remove material. In contrast, ICP (Inductively Coupled Plasma) etching generates high-density plasma through induction, enhancing ion density and etch rate but typically without the cyclical passivation that DRIE employs. Your choice between DRIE and ICP depends on the required etch depth, profile precision, and material selectivity for your microfabrication process.

Fundamental Principles of ICP

Inductively Coupled Plasma (ICP) etching relies on high-density plasma generated by electromagnetic fields to produce chemically reactive ions that selectively remove material with high precision. Fundamental principles of ICP include generating a plasma source through RF power coupled into an inductive coil, creating a dense ion cloud for enhanced anisotropic etching rates. Compared to Deep Reactive Ion Etching (DRIE), ICP offers superior control over ion energy and plasma density, improving etch uniformity and selectivity for microfabrication applications.

Key Differences Between DRIE and ICP

DRIE (Deep Reactive Ion Etching) offers highly anisotropic etching with deep, narrow features ideal for MEMS and semiconductor applications, while ICP (Inductively Coupled Plasma) provides high-density plasma for faster, more uniform etching over larger areas. DRIE typically achieves aspect ratios greater than 20:1 through cyclic passivation and etching steps, whereas ICP focuses on precise control of ion energy and density for fine pattern transfer. Your choice between DRIE and ICP depends on the specific requirements for etch depth, profile precision, and throughput in microfabrication processes.

Applications of DRIE in Semiconductor Manufacturing

Deep Reactive Ion Etching (DRIE) is predominantly used in semiconductor manufacturing for creating high-aspect-ratio microstructures, essential for MEMS devices, advanced packaging, and through-silicon vias (TSVs). This etching technique allows precise control over feature dimensions, enabling the fabrication of complex, high-density circuits and sensors. DRIE's capability to produce deep, anisotropic etches distinguishes it from Inductively Coupled Plasma (ICP) etching, making it vital for next-generation semiconductor applications requiring fine, vertical sidewalls.

Applications of ICP in Microfabrication

ICP (Inductively Coupled Plasma) is widely used in microfabrication for precise etching of complex patterns in semiconductor devices, MEMS, and microelectromechanical systems. Its high-density plasma and low ion energy make it ideal for anisotropic etching of materials like silicon, silicon dioxide, and polymers, enabling the creation of high-aspect-ratio features with smooth sidewalls. Your advanced microfabrication processes benefit from ICP's ability to deliver uniform etching and better control over etch profiles compared to DRIE (Deep Reactive Ion Etching).

Process Advantages of DRIE

Deep Reactive Ion Etching (DRIE) offers superior anisotropy and high aspect ratio etching compared to Inductively Coupled Plasma (ICP) etching, enabling precise micro- and nano-scale patterning essential for MEMS and semiconductor devices. The DRIE process features enhanced selectivity and minimized sidewall roughness due to its cyclic passivation and etching steps, improving structural integrity and performance. DRIE also provides faster etch rates and deeper etching capabilities, making it favored for complex 3D microfabrication applications.

Process Advantages of ICP

ICP (Inductively Coupled Plasma) etching offers superior process advantages over DRIE (Deep Reactive Ion Etching) in terms of uniformity and selectivity, allowing for precise material removal with minimal surface damage. ICP enables high-density plasma generation, resulting in faster etch rates and better control over feature profiles, crucial for advanced microfabrication applications such as MEMS and semiconductor device manufacturing. The lower ion energy in ICP also reduces substrate heating, enhancing process stability and extending tool lifespan compared to DRIE.

Comparative Performance: DRIE vs ICP

DRIE (Deep Reactive Ion Etching) provides highly anisotropic etching with superior aspect ratios and smoother sidewalls, making it ideal for precise microfabrication compared to ICP (Inductively Coupled Plasma) etching. ICP offers higher etch rates and better control over plasma density, enhancing throughput but often at the expense of sidewall quality and selectivity. Overall, DRIE excels in applications requiring fine detail and vertical profiles, while ICP suits faster etching processes with moderate anisotropy.

Choosing the Right Etching Technique: DRIE or ICP

Choosing between Deep Reactive Ion Etching (DRIE) and Inductively Coupled Plasma (ICP) etching depends on the desired etch profile and application precision. DRIE excels in creating high aspect ratio features with vertical sidewalls essential for MEMS and microsystems, while ICP offers higher etch rates and better control for shallow, uniform etching of materials like silicon and glass. Selecting the optimal technique requires balancing factors such as etch depth, sidewall smoothness, and process complexity to achieve specific microfabrication goals.

DRIE vs ICP Infographic

libmatt.com

libmatt.com