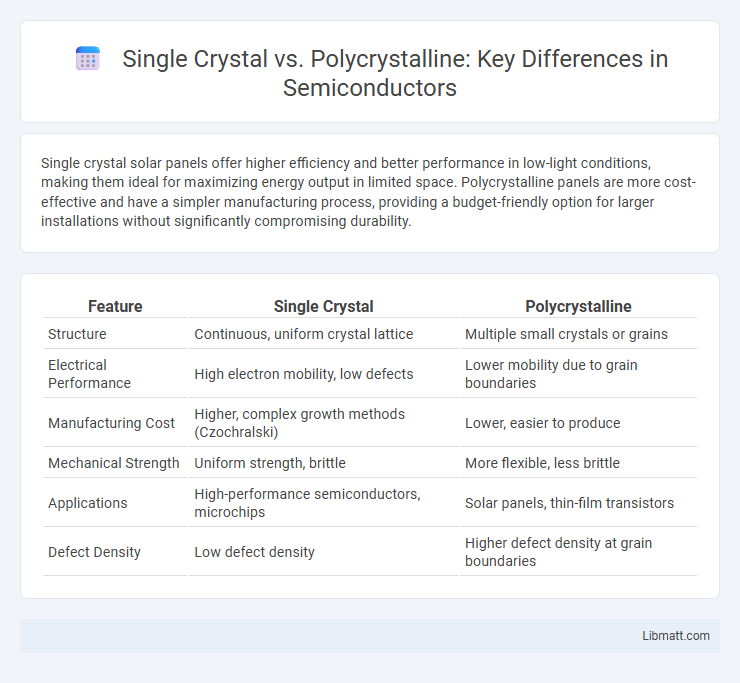

Single crystal solar panels offer higher efficiency and better performance in low-light conditions, making them ideal for maximizing energy output in limited space. Polycrystalline panels are more cost-effective and have a simpler manufacturing process, providing a budget-friendly option for larger installations without significantly compromising durability.

Table of Comparison

| Feature | Single Crystal | Polycrystalline |

|---|---|---|

| Structure | Continuous, uniform crystal lattice | Multiple small crystals or grains |

| Electrical Performance | High electron mobility, low defects | Lower mobility due to grain boundaries |

| Manufacturing Cost | Higher, complex growth methods (Czochralski) | Lower, easier to produce |

| Mechanical Strength | Uniform strength, brittle | More flexible, less brittle |

| Applications | High-performance semiconductors, microchips | Solar panels, thin-film transistors |

| Defect Density | Low defect density | Higher defect density at grain boundaries |

Introduction to Crystal Structures

Single crystal solar cells consist of a continuous, unbroken lattice structure with atoms arranged uniformly, allowing efficient electron flow and higher energy conversion rates. Polycrystalline cells are composed of multiple small silicon crystals or grains, creating grain boundaries that can impede electron movement and slightly reduce efficiency. The structural differences between single crystal and polycrystalline materials directly influence solar cell performance and manufacturing costs.

Understanding Single Crystal Materials

Single crystal materials consist of a continuous and unbroken lattice structure without grain boundaries, resulting in superior electrical conductivity, enhanced mechanical strength, and higher efficiency in applications such as solar cells and semiconductors. Their uniform atomic arrangement minimizes defects and electron scattering, which improves performance compared to polycrystalline materials composed of multiple crystallites separated by grain boundaries. Understanding the intrinsic properties of single crystal materials is crucial for optimizing the design and functionality of high-performance electronic devices and photovoltaic systems.

Overview of Polycrystalline Materials

Polycrystalline materials consist of numerous small crystallites or grains, each with a different orientation, which results in grain boundaries that influence their mechanical and electrical properties. Common in solar panels, polycrystalline silicon offers a cost-effective alternative to single crystal silicon, though it typically exhibits lower efficiency due to its structural complexity. These materials provide advantages in manufacturing scalability and material utilization while balancing performance limitations compared to single crystal counterparts.

Key Differences Between Single Crystal and Polycrystalline

Single crystal materials consist of a continuous and unbroken lattice structure with no grain boundaries, resulting in superior electrical efficiency and mechanical strength compared to polycrystalline materials, which are composed of multiple small silicon crystals. Polycrystalline cells, made by melting raw silicon fragments, exhibit lower manufacturing costs but reduced performance due to grain boundaries that scatter electrons. Your choice between single crystal and polycrystalline impacts the overall effectiveness and budget of solar panels, with single crystal offering higher efficiency and polycrystalline providing cost savings.

Mechanical Properties Comparison

Single crystal materials exhibit superior mechanical properties such as higher strength, greater fracture toughness, and improved resistance to crack propagation due to the absence of grain boundaries. Polycrystalline materials, composed of multiple crystallites, often display enhanced hardness and better resistance to fatigue because grain boundaries can impede dislocation movement. Your choice between single crystal and polycrystalline structures should consider application-specific mechanical demands, as single crystals excel in environments requiring high durability and precision, while polycrystalline forms provide cost-effective robustness.

Electrical and Thermal Conductivity

Single crystal materials exhibit superior electrical and thermal conductivity due to their uniform atomic structure, which minimizes electron scattering and phonon disruption. Polycrystalline materials contain grain boundaries that act as barriers, reducing conductivity and overall efficiency. Optimizing your choice between single crystal and polycrystalline can significantly impact performance in applications requiring high conductivity.

Manufacturing Processes and Costs

Single crystal solar panels are manufactured through the Czochralski process, which involves growing a single, continuous crystal ingot, making production time-consuming and costly due to high energy consumption and stringent purity requirements. Polycrystalline panels are produced by melting silicon fragments together in molds, a simpler and faster process that reduces manufacturing costs but results in lower efficiency. The higher yield and lower material waste in polycrystalline production contribute to its cost-effectiveness compared to the precision and labor-intensive techniques required for single crystal manufacture.

Applications in Industry and Technology

Single crystal materials, known for their uniform atomic structure, are essential in high-precision applications such as semiconductor wafers, aerospace turbine blades, and optical devices due to their superior mechanical and electronic properties. Polycrystalline materials, composed of multiple crystals or grains, are widely used in industries like solar panels, construction, and automotive components because of their cost-effectiveness and easier manufacturing processes. Your choice between single crystal and polycrystalline materials depends on the required performance, durability, and budget constraints within your specific technology or industrial application.

Advantages and Disadvantages

Single crystal solar panels offer higher efficiency and better performance in low-light conditions due to their uniform silicon structure, but they come with higher production costs and greater fragility. Polycrystalline panels are less expensive to manufacture and more resistant to heat, yet they have lower efficiency and a less uniform appearance because of their multiple silicon crystals. Choosing between single crystal and polycrystalline depends on budget constraints and specific application requirements, balancing cost against energy output.

Future Trends in Crystal Material Development

Future trends in crystal material development emphasize enhancing the efficiency and durability of single crystal and polycrystalline technologies for renewable energy applications, particularly in solar cells. Advances in single crystal growth techniques are improving electron mobility and reducing defects, while innovations in polycrystalline materials aim to lower production costs and increase scalability through improved grain boundary passivation. Emerging hybrid approaches that combine the superior charge transport properties of single crystals with the cost-effectiveness of polycrystalline structures are becoming a focal point in next-generation semiconductor research.

Single Crystal vs Polycrystalline Infographic

libmatt.com

libmatt.com