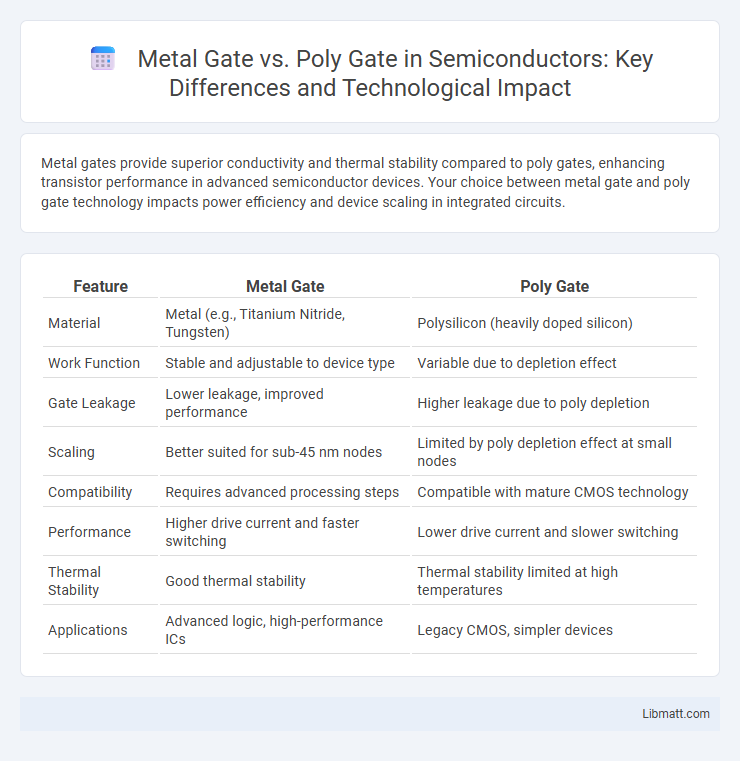

Metal gates provide superior conductivity and thermal stability compared to poly gates, enhancing transistor performance in advanced semiconductor devices. Your choice between metal gate and poly gate technology impacts power efficiency and device scaling in integrated circuits.

Table of Comparison

| Feature | Metal Gate | Poly Gate |

|---|---|---|

| Material | Metal (e.g., Titanium Nitride, Tungsten) | Polysilicon (heavily doped silicon) |

| Work Function | Stable and adjustable to device type | Variable due to depletion effect |

| Gate Leakage | Lower leakage, improved performance | Higher leakage due to poly depletion |

| Scaling | Better suited for sub-45 nm nodes | Limited by poly depletion effect at small nodes |

| Compatibility | Requires advanced processing steps | Compatible with mature CMOS technology |

| Performance | Higher drive current and faster switching | Lower drive current and slower switching |

| Thermal Stability | Good thermal stability | Thermal stability limited at high temperatures |

| Applications | Advanced logic, high-performance ICs | Legacy CMOS, simpler devices |

Introduction to Metal Gate and Poly Gate Technologies

Metal gate technology utilizes metals like titanium or tantalum for improved conductivity and reduced gate leakage in semiconductor devices, while poly gate employs polysilicon as the gate material. Your choice between metal gate and poly gate impacts transistor performance, power consumption, and scaling capabilities in integrated circuits. Metal gates offer superior performance in high-k dielectric stacks, overcoming polysilicon depletion effects common in poly gate technology.

Key Differences Between Metal Gate and Poly Gate

Metal gates offer lower resistivity and better conductivity compared to poly gates, significantly improving transistor performance in advanced CMOS technologies. Poly gates, traditionally made from doped polysilicon, tend to suffer from higher gate depletion effects, whereas metal gates eliminate this problem, enabling higher drive currents and reduced power consumption. The compatibility of metal gates with high-k dielectrics enhances gate control and reduces leakage currents, marking a critical advancement over poly gates in modern semiconductor devices.

Historical Evolution of Gate Materials

The historical evolution of gate materials transitioned from polysilicon gates, dominant since the 1970s for their compatibility with CMOS processes, to metal gates introduced in the early 2000s to overcome polysilicon depletion and high resistance issues. Metal gates enabled high-k dielectric integration, significantly improving transistor performance and scaling beyond the 45nm technology node. This shift marked a pivotal advancement in semiconductor manufacturing, enhancing drive current and reducing leakage in modern CMOS devices.

Electrical Performance Comparison

Metal gates exhibit superior electrical performance compared to poly gates due to their lower gate resistance and enhanced work function tunability, which results in reduced threshold voltage variability and improved drive current. Poly gates suffer from polysilicon depletion effects that degrade channel control and increase gate leakage, impacting device reliability and scaling. Metal gates also enable better compatibility with high-k dielectrics, further minimizing gate leakage and improving overall transistor performance in advanced CMOS technologies.

Impact on Scaling and Miniaturization

Metal gates significantly improve scaling and miniaturization by reducing gate depletion and enabling lower equivalent oxide thickness (EOT), which enhances transistor performance at smaller nodes compared to poly gates. Poly gates face issues with polysilicon depletion and gate leakage as device dimensions shrink, limiting their effectiveness in advanced technology nodes below 45nm. The adoption of metal gates in combination with high-k dielectrics has become essential for continued transistor scaling in sub-10nm semiconductor manufacturing processes.

Reliability and Durability Concerns

Metal gates offer superior reliability and durability compared to poly gates due to their resistance to heat and electrical stress, which reduces gate leakage and performance degradation over time. Poly gates tend to suffer from increased susceptibility to wear and charge trapping, impacting long-term stability in semiconductor devices. Choosing a metal gate can enhance your device's lifespan and maintain consistent electrical characteristics under demanding conditions.

Fabrication Process and Complexity

Metal gate fabrication involves depositing a metal layer directly onto the gate dielectric, simplifying process steps compared to poly gate methods that require polysilicon deposition, doping, and annealing. Metal gates reduce thermal budget and prevent dopant diffusion issues inherent in poly gates, resulting in fewer process complexities and better interface control. The integration of high-k dielectrics with metal gates enhances device performance but demands precise control of work function and thickness during fabrication.

Cost Implications: Metal Gate vs Poly Gate

Metal gate technology generally incurs higher manufacturing costs compared to poly gate due to complex deposition and etching processes required for metals like titanium or tantalum. Poly gates, made from heavily doped polysilicon, offer cost-efficiency with simpler fabrication techniques and compatibility with existing CMOS processes. However, advanced nodes benefit from metal gates' improved performance and reduced power consumption, potentially offsetting initial cost differences in high-performance applications.

Industry Adoption and Trends

Metal gates have gained significant momentum in advanced semiconductor manufacturing due to their superior electrical performance and compatibility with high-k dielectric materials, driving widespread adoption in cutting-edge CMOS technologies. Poly gates, once the industry standard, are increasingly being replaced because they suffer from higher gate leakage and scalability issues in sub-20nm nodes. Your choice between metal and poly gate materials should align with device performance requirements and future-proofing needs in rapidly evolving semiconductor design trends.

Future Prospects and Innovations

Metal gates in semiconductor devices offer superior scalability and reduced gate leakage compared to poly gates, making them crucial for future transistor architectures like FinFETs and gate-all-around FETs. Innovations in high-k dielectric integration with metal gates enable enhanced performance and energy efficiency in advanced nodes beyond 5nm technology. Continued research in metal gate materials and work function engineering drives the evolution of ultra-low power and high-speed microprocessors for emerging applications such as AI and 5G networks.

Metal Gate vs Poly Gate Infographic

libmatt.com

libmatt.com