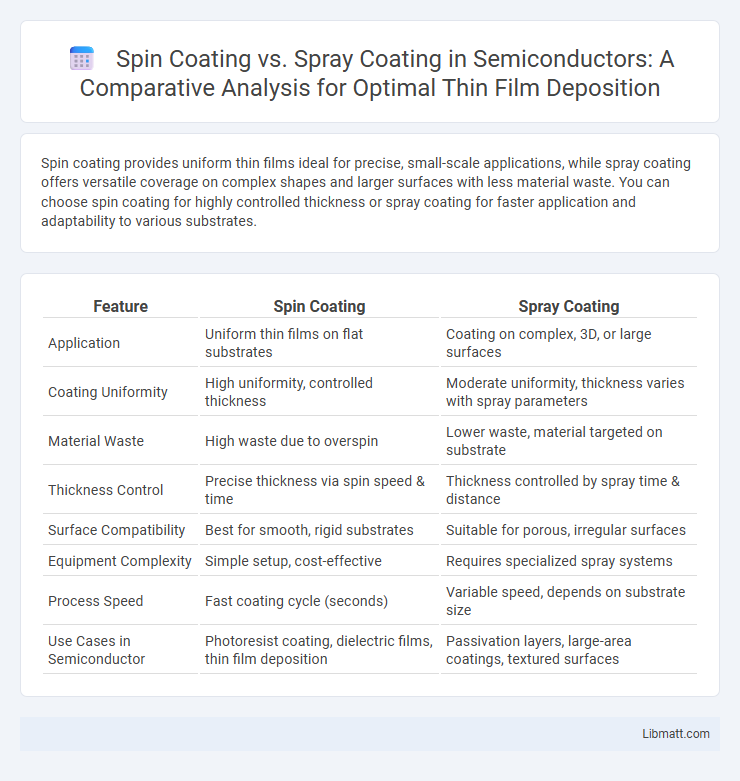

Spin coating provides uniform thin films ideal for precise, small-scale applications, while spray coating offers versatile coverage on complex shapes and larger surfaces with less material waste. You can choose spin coating for highly controlled thickness or spray coating for faster application and adaptability to various substrates.

Table of Comparison

| Feature | Spin Coating | Spray Coating |

|---|---|---|

| Application | Uniform thin films on flat substrates | Coating on complex, 3D, or large surfaces |

| Coating Uniformity | High uniformity, controlled thickness | Moderate uniformity, thickness varies with spray parameters |

| Material Waste | High waste due to overspin | Lower waste, material targeted on substrate |

| Thickness Control | Precise thickness via spin speed & time | Thickness controlled by spray time & distance |

| Surface Compatibility | Best for smooth, rigid substrates | Suitable for porous, irregular surfaces |

| Equipment Complexity | Simple setup, cost-effective | Requires specialized spray systems |

| Process Speed | Fast coating cycle (seconds) | Variable speed, depends on substrate size |

| Use Cases in Semiconductor | Photoresist coating, dielectric films, thin film deposition | Passivation layers, large-area coatings, textured surfaces |

Introduction to Spin Coating and Spray Coating

Spin coating involves depositing a liquid solution onto a substrate, then rapidly spinning it to create a uniform thin film, widely used in microelectronics and optical coatings. Spray coating disperses a liquid or powder material onto a surface using a spray nozzle, ideal for covering large or irregular substrates with materials like paints, polymers, and nanoparticles. Your choice between these methods depends on the desired film thickness, uniformity, and substrate geometry.

Principles of Spin Coating

Spin coating utilizes centrifugal force to evenly distribute a liquid coating onto a substrate by rapidly spinning it, typically between 1000 to 6000 RPM. The process controls coating thickness through rotation speed and solution viscosity, producing uniform thin films in microfabrication and electronics. Spin coating is preferred for its precision in achieving nanoscale thickness and smooth, defect-free surfaces.

Principles of Spray Coating

Spray coating involves atomizing a liquid coating material into fine droplets and depositing them uniformly onto a surface using a spray nozzle, allowing for even coverage over complex geometries. This method relies on factors such as spray pressure, nozzle design, and distance to control droplet size and coating thickness, resulting in enhanced adhesion and surface finish. Your choice between spin coating and spray coating depends on the required film uniformity and substrate shape, with spray coating offering superior adaptability for irregular surfaces.

Material Compatibility and Surface Requirements

Spin coating excels in applying uniform thin films on flat, smooth substrates such as silicon wafers and glass, supporting materials like photoresists, polymers, and sol-gels. Spray coating offers greater versatility for complex geometries and rough surfaces, accommodating viscous materials, powders, and particulate suspensions. Material compatibility in spray coating includes metals, ceramics, and composites, while spin coating is limited by substrate size and shape constraints.

Coating Thickness Control and Uniformity

Spin coating offers precise control over coating thickness and uniformity by adjusting spin speed, acceleration, and viscosity, resulting in highly uniform thin films ideal for microelectronics and optics. Spray coating allows for thicker, more variable layers with less precision in thickness control but is advantageous for covering large or irregular surfaces quickly. Your choice depends on the required uniformity and thickness precision, with spin coating excelling in consistency and spray coating in versatility.

Equipment and Process Setup

Spin coating equipment consists of a motorized chuck to hold and rotate the substrate at high speeds, a dispensing system for applying the coating solution, and a controller to regulate speed and duration. The process setup requires precise control of rotational speed (typically 500 to 6000 RPM) and solution volume to achieve uniform film thickness. Spray coating utilizes spray guns or nozzles connected to a compressed air system, allowing for adjustable spray patterns and flow rates, making it suitable for larger or irregular surfaces with minimal substrate contact.

Advantages of Spin Coating

Spin coating offers superior film uniformity and thickness control compared to spray coating, making it ideal for producing highly consistent thin films in microelectronics and optics. The method enables rapid processing with minimal material waste due to its efficient use of coating solution. Precise reproducibility and compatibility with a wide range of materials contribute to its advantage in research and industrial applications.

Advantages of Spray Coating

Spray coating offers superior versatility by accommodating complex geometries and large surface areas that spin coating cannot efficiently cover. Its ability to apply uniform thin films quickly reduces material waste and enhances production speed, making it ideal for high-throughput manufacturing. Choosing spray coating for your project ensures better control over coating thickness and surface finish, especially for irregular or uneven substrates.

Limitations and Challenges of Each Method

Spin coating faces limitations such as non-uniform coating on large or irregularly shaped substrates and significant material waste due to excess solution spinning off the edges. Spray coating struggles with challenges like lower film thickness control, overspray causing material loss, and difficulties achieving uniform coatings on complex geometries. Both methods must address challenges related to scalability, reproducibility, and environmental impact of solvents used in the coating processes.

Application Areas and Industry Use Cases

Spin coating is widely utilized in semiconductor manufacturing, microelectronics, and thin film deposition due to its precision in creating uniform coatings on flat substrates. Spray coating finds extensive use in automotive, aerospace, and construction industries, offering versatility for applying coatings on irregular or large surfaces. Both techniques serve critical roles in protective coatings, optical devices, and surface functionalization across diverse industrial applications.

Spin Coating vs Spray Coating Infographic

libmatt.com

libmatt.com