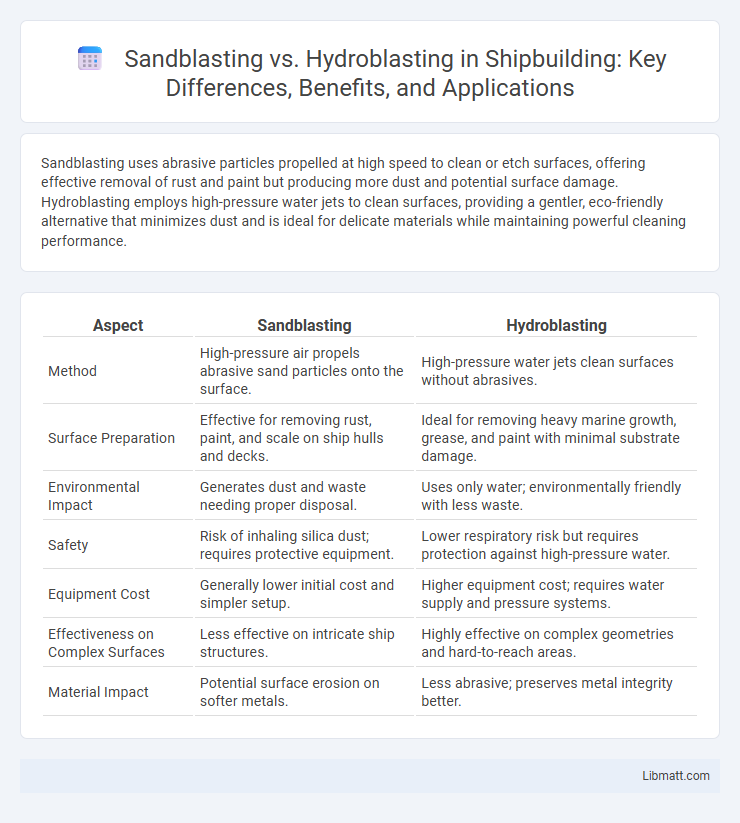

Sandblasting uses abrasive particles propelled at high speed to clean or etch surfaces, offering effective removal of rust and paint but producing more dust and potential surface damage. Hydroblasting employs high-pressure water jets to clean surfaces, providing a gentler, eco-friendly alternative that minimizes dust and is ideal for delicate materials while maintaining powerful cleaning performance.

Table of Comparison

| Aspect | Sandblasting | Hydroblasting |

|---|---|---|

| Method | High-pressure air propels abrasive sand particles onto the surface. | High-pressure water jets clean surfaces without abrasives. |

| Surface Preparation | Effective for removing rust, paint, and scale on ship hulls and decks. | Ideal for removing heavy marine growth, grease, and paint with minimal substrate damage. |

| Environmental Impact | Generates dust and waste needing proper disposal. | Uses only water; environmentally friendly with less waste. |

| Safety | Risk of inhaling silica dust; requires protective equipment. | Lower respiratory risk but requires protection against high-pressure water. |

| Equipment Cost | Generally lower initial cost and simpler setup. | Higher equipment cost; requires water supply and pressure systems. |

| Effectiveness on Complex Surfaces | Less effective on intricate ship structures. | Highly effective on complex geometries and hard-to-reach areas. |

| Material Impact | Potential surface erosion on softer metals. | Less abrasive; preserves metal integrity better. |

Introduction: Understanding Surface Cleaning Methods

Sandblasting uses abrasive materials propelled at high speeds to remove surface contaminants, offering effective cleaning and surface preparation for metals, concrete, and wood. Hydroblasting employs high-pressure water jets to clean surfaces without abrasive media, making it ideal for delicate materials or areas requiring minimal surface damage. Your choice between sandblasting and hydroblasting depends on the surface type, desired finish, and environmental considerations.

What is Sandblasting?

Sandblasting is an abrasive cleaning technique that uses high-pressure air to propel fine particles of sand or other abrasive materials against a surface, effectively removing rust, paint, and contaminants. This method is widely utilized in industrial applications to prepare metal surfaces for coating or restoration by creating a clean, roughened texture. Sandblasting equipment varies from handheld devices to large automated systems, enabling precise and efficient surface preparation.

What is Hydroblasting?

Hydroblasting, also known as water blasting, uses high-pressure water jets to clean, strip, or prepare surfaces without abrasive materials, making it ideal for delicate or heat-sensitive substrates. Unlike sandblasting, which propels abrasive particles, hydroblasting relies solely on pressurized water to remove contaminants, paint, rust, or coatings efficiently and environmentally friendly. Your choice between these methods depends on the surface condition, desired finish, and the need to minimize dust or residue during cleaning.

Key Differences Between Sandblasting and Hydroblasting

Sandblasting uses abrasive materials like sand propelled at high speed to clean or etch surfaces, while hydroblasting employs high-pressure water jets for similar purposes without abrasive particles. Hydroblasting is preferable for delicate surfaces and environmentally sensitive areas due to reduced dust and chemical residue, whereas sandblasting offers more aggressive cleaning suitable for heavy rust or paint removal. Your choice depends on the material's condition and environmental considerations, with hydroblasting providing a safer, more precise cleaning method compared to the abrasive intensity of sandblasting.

Advantages of Sandblasting

Sandblasting offers superior abrasive power for removing tough coatings, rust, and paint from metal surfaces, ensuring a clean finish ideal for industrial applications. This method provides precise control over surface texture, enhancing paint and coating adhesion while preparing surfaces for further treatment. Economically, sandblasting is cost-effective due to its low equipment expenses and ready availability of abrasive materials, making it ideal for large-scale projects.

Advantages of Hydroblasting

Hydroblasting offers superior cleaning power by using high-pressure water jets, effectively removing contaminants without abrasive residue, making it ideal for sensitive surfaces. It reduces dust and airborne particles, enhancing workplace safety and minimizing environmental impact compared to sandblasting. Hydroblasting also extends equipment lifespan by preventing surface damage often caused by abrasive media in sandblasting.

Safety Considerations: Sandblasting vs Hydroblasting

Sandblasting involves abrasive particles that can cause respiratory issues and surface contamination, requiring protective gear like respirators and containment measures. Hydroblasting uses high-pressure water jets, reducing airborne dust but posing risks of injection injuries and splashback, necessitating waterproof suits and shields. Your choice should weigh the specific safety protocols and hazard management for each method to ensure a secure working environment.

Environmental Impact: Which Method is Greener?

Sandblasting generates significant dust and debris, often requiring hazardous material disposal, which can negatively impact the environment. Hydroblasting uses high-pressure water to clean surfaces without producing airborne contaminants, making it a more eco-friendly option. Your choice of hydroblasting minimizes waste and reduces the risk of soil and air pollution, positioning it as the greener cleaning method.

Ideal Applications for Sandblasting and Hydroblasting

Sandblasting is ideal for surface preparation on metal, concrete, and wood, effectively removing rust, paint, and scale to ensure a smooth finish. Hydroblasting excels in cleaning large industrial equipment, removing stubborn contaminants like oil and grease without damaging the substrate, making it suitable for pipelines and heat exchangers. Both methods offer precise cleaning solutions, with sandblasting preferred for abrasive surface treatment and hydroblasting favored for environmentally safe, high-pressure water cleaning.

Choosing the Right Method: Factors to Consider

Choosing between sandblasting and hydroblasting depends primarily on the surface material, desired finish, and environmental considerations. Sandblasting excels in removing tough coatings and rust from metal surfaces but may cause abrasions, while hydroblasting uses high-pressure water to clean delicate surfaces without dust or chemical residue. Assessing factors such as surface sensitivity, project scale, and safety requirements ensures you select the most effective cleaning method for your needs.

Sandblasting vs hydroblasting Infographic

libmatt.com

libmatt.com