A butt joint connects two pieces of material end-to-end, creating a simple, flat seam that is easy to assemble but may require reinforcement for strength. A lap joint overlaps two materials, providing greater surface area for bonding or welding, making it more durable and resistant to shear forces for your structural projects.

Table of Comparison

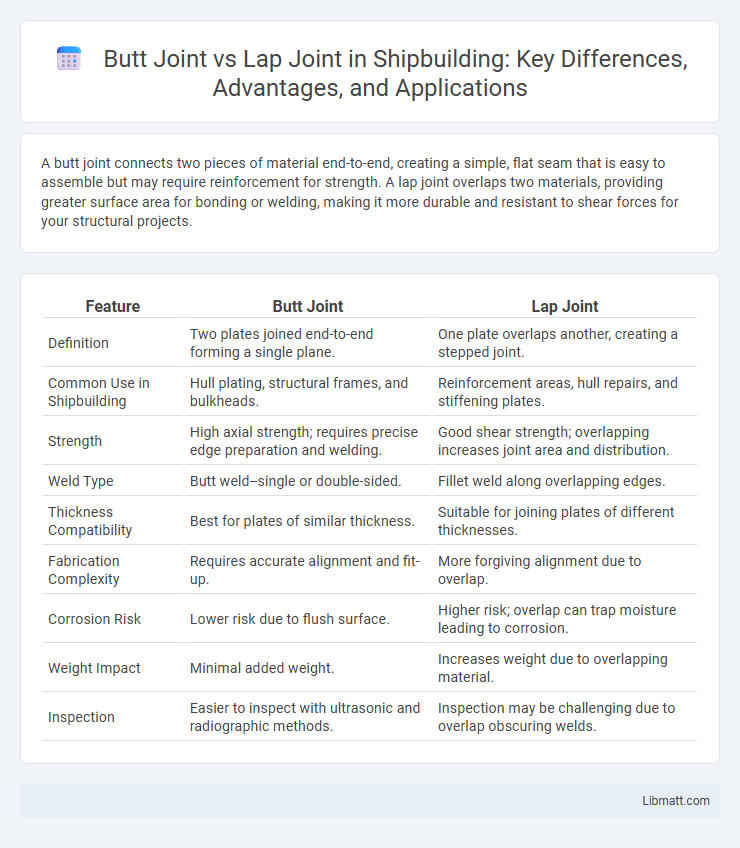

| Feature | Butt Joint | Lap Joint |

|---|---|---|

| Definition | Two plates joined end-to-end forming a single plane. | One plate overlaps another, creating a stepped joint. |

| Common Use in Shipbuilding | Hull plating, structural frames, and bulkheads. | Reinforcement areas, hull repairs, and stiffening plates. |

| Strength | High axial strength; requires precise edge preparation and welding. | Good shear strength; overlapping increases joint area and distribution. |

| Weld Type | Butt weld--single or double-sided. | Fillet weld along overlapping edges. |

| Thickness Compatibility | Best for plates of similar thickness. | Suitable for joining plates of different thicknesses. |

| Fabrication Complexity | Requires accurate alignment and fit-up. | More forgiving alignment due to overlap. |

| Corrosion Risk | Lower risk due to flush surface. | Higher risk; overlap can trap moisture leading to corrosion. |

| Weight Impact | Minimal added weight. | Increases weight due to overlapping material. |

| Inspection | Easier to inspect with ultrasonic and radiographic methods. | Inspection may be challenging due to overlap obscuring welds. |

Introduction to Butt Joint and Lap Joint

A butt joint is a simple connection where two pieces of material are joined end-to-end or edge-to-edge without overlapping, commonly used in welding and woodworking for straightforward, linear assemblies. A lap joint involves overlapping two materials and fastening them together, offering increased surface area for bonding and greater strength in applications like metal fabrication and carpentry. Understanding the differences between these joints helps you select the appropriate technique for structural integrity and ease of fabrication in your projects.

Key Differences Between Butt Joints and Lap Joints

Butt joints connect two components end-to-end, creating a seamless extension often used in welding and woodworking, whereas lap joints involve overlapping sections welded or fastened together to increase contact area and strength. Butt joints typically require precise edge preparation for optimal strength, while lap joints benefit from a larger surface area, enhancing load-bearing capacity. The choice between butt and lap joints depends on factors such as material thickness, structural load requirements, and application type, with lap joints preferred for added durability and butt joints favored for streamlined assembly.

Structural Strength Comparison

Butt joints generally exhibit lower structural strength compared to lap joints due to their single-plane connection, which concentrates stress at the joint interface. Lap joints provide enhanced load distribution and increased surface area for bonding or welding, resulting in superior tensile and shear strength. Engineering applications often favor lap joints in high-stress scenarios where rigidity and durability are critical factors.

Common Applications of Butt Joints

Butt joints are commonly used in structural steel fabrication, pipeline welding, and frame construction where two pieces of metal are joined end-to-end for a seamless connection. This joint type is ideal for high-strength applications such as bridges, buildings, and pressure vessels due to its ability to distribute stress evenly across the welded area. Butt joints also appear in sheet metal work, automotive frames, and aerospace manufacturing where smooth surfaces and precise alignment are critical.

Common Applications of Lap Joints

Lap joints are widely used in automotive frames, shipbuilding, and machinery fabrication due to their ability to distribute loads evenly across overlapping materials. These joints provide increased surface area for welding or adhesive bonding, making them ideal for structural applications requiring enhanced strength and durability. Your projects involving metal or wood assemblies will benefit from the lap joint's simple design and superior load-bearing capacity compared to butt joints.

Ease of Construction and Assembly

Butt joints offer straightforward ease of construction due to their simple end-to-end alignment, requiring minimal preparation and tools. Lap joints provide increased stability during assembly by overlapping materials, but this can involve more precise cutting and fitting. Your choice depends on the balance between quick assembly and the need for joint strength in your project.

Material and Tool Requirements

Butt joints typically require precise edge preparation and clean, straight cuts on materials like metal or wood, demanding tools such as saws, grinders, or welding machines tailored to the specific material. Lap joints involve overlapping materials, often necessitating less precise cutting but requiring clamps or fixtures to hold the pieces during welding or fastening, with tools suited for the thicker combined sections. Your choice between these joints depends on the available tools and material thickness, influencing both the ease of fabrication and joint strength.

Aesthetic Considerations

Butt joints offer a clean and minimalistic appearance by aligning two edges flush, making them ideal for visible seams in furniture and cabinetry. Lap joints create overlapping sections, which can result in a bulkier look but provide a rustic or handcrafted aesthetic suited for traditional woodworking projects. Choosing between these joints depends on the desired visual impact and the balance between appearance and structural integrity.

Pros and Cons of Butt Joints and Lap Joints

Butt joints offer simplicity and ease of fabrication, making them ideal for quick assembly, but they typically provide lower strength and require additional reinforcement compared to other joints. Lap joints create a larger surface area for bonding, resulting in greater strength and durability, though they can be more complex to fabricate and may add weight or material cost. Your choice depends on the specific structural requirements and fabrication constraints of your project.

Choosing the Right Joint for Your Project

Butt joints are ideal for projects requiring a flush surface and are commonly used in frame construction, offering simplicity and ease of assembly. Lap joints provide increased strength and stability by overlapping materials, making them suitable for load-bearing applications and outdoor structures. Selecting the right joint depends on factors like material thickness, load requirements, and desired aesthetic finish to ensure structural integrity and project longevity.

Butt joint vs lap joint Infographic

libmatt.com

libmatt.com