Sanforizing is a textile process that preshrinks fabric to prevent shrinkage after washing, ensuring consistent garment size and fit. Heat setting stabilizes synthetic fibers by applying controlled heat to lock in shape and improve fabric durability, which enhances your clothing's overall performance.

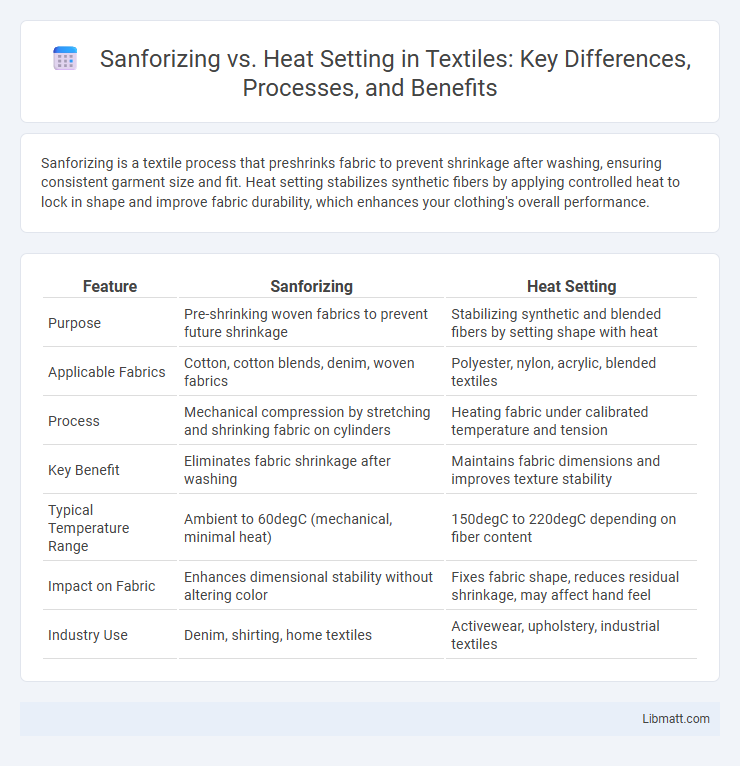

Table of Comparison

| Feature | Sanforizing | Heat Setting |

|---|---|---|

| Purpose | Pre-shrinking woven fabrics to prevent future shrinkage | Stabilizing synthetic and blended fibers by setting shape with heat |

| Applicable Fabrics | Cotton, cotton blends, denim, woven fabrics | Polyester, nylon, acrylic, blended textiles |

| Process | Mechanical compression by stretching and shrinking fabric on cylinders | Heating fabric under calibrated temperature and tension |

| Key Benefit | Eliminates fabric shrinkage after washing | Maintains fabric dimensions and improves texture stability |

| Typical Temperature Range | Ambient to 60degC (mechanical, minimal heat) | 150degC to 220degC depending on fiber content |

| Impact on Fabric | Enhances dimensional stability without altering color | Fixes fabric shape, reduces residual shrinkage, may affect hand feel |

| Industry Use | Denim, shirting, home textiles | Activewear, upholstery, industrial textiles |

Introduction to Sanforizing and Heat Setting

Sanforizing is a textile finishing process designed to pre-shrink fabric, ensuring minimal shrinkage after washing by stabilizing fibers through controlled moist heat and mechanical action. Heat setting, commonly applied to synthetic fibers like polyester, uses precise temperature control to lock molecular structures and improve dimensional stability, wrinkle resistance, and fabric performance. Both processes enhance fabric quality but target different fiber types and achieve shrinkage control through distinct mechanisms.

Definition of Sanforizing

Sanforizing is a textile finishing process designed to pre-shrink cotton fabrics, ensuring dimensional stability and preventing further shrinkage during washing. Heat setting involves applying controlled heat to synthetic fibers to stabilize their shape and size, but Sanforizing specifically targets natural fibers like cotton. This process compresses and stretches the fabric under precise conditions, locking in the fabric's dimensions permanently.

Definition of Heat Setting

Heat setting is a thermal process used primarily in synthetic fabrics to stabilize fibers and eliminate shrinkage caused by residual tensions from manufacturing. Unlike sanforizing, which mechanically compresses and stabilizes woven cotton fabrics, heat setting involves exposing textile materials to controlled high temperatures to fix their dimensional stability and enhance durability. Your garments treated with heat setting maintain consistent shape and size after washing, ensuring long-term performance and comfort.

Process Overview: Sanforizing

Sanforizing is a controlled process that pre-shrinks fabric by mechanically compressing it using a rubber belt or a sanforizing machine. The fabric is moistened, stretched, and then passed through heated rollers while being pressed against the rubber belt to ensure dimensional stability. This process reduces shrinkage in finished garments, enhancing fabric durability and fit.

Process Overview: Heat Setting

Heat setting is a crucial finishing process in textile manufacturing that stabilizes synthetic fibers like polyester by applying controlled heat to lock in fabric dimensions. This process prevents shrinkage and deformation caused by subsequent washing or drying, ensuring consistent fabric performance. Your textiles retain their shape and strength, improving durability and overall quality.

Key Differences Between Sanforizing and Heat Setting

Sanforizing is a mechanical process that pre-shrinks woven fabrics to minimize post-production shrinkage, while heat setting involves treating synthetic fibers with controlled heat to stabilize their dimensions and enhance fabric properties. Your choice depends on fabric type; sanforizing suits natural fibers like cotton, whereas heat setting is essential for polyester or nylon blends. Understanding these key differences ensures optimal fabric performance and garment quality in textile production.

Advantages of Sanforizing

Sanforizing significantly reduces fabric shrinkage, ensuring better garment fit and durability, which is crucial for maintaining product quality and customer satisfaction. The process enhances fabric softness and stability without compromising breathability, making your clothing more comfortable and long-lasting. Unlike heat setting, sanforizing provides a permanent mechanical pre-shrinking treatment that prevents post-purchase distortion.

Advantages of Heat Setting

Heat setting stabilizes synthetic and blended fabrics by permanently fixing fibers, reducing shrinkage and improving dimensional stability. This process enhances fabric resilience, ensuring garments maintain their shape and size through repeated washing and wear. It also improves surface smoothness and fabric hand, resulting in higher-quality textiles with superior appearance and durability.

Applications in Textile Industry

Sanforizing is widely used in the textile industry to pre-shrink cotton fabrics, ensuring dimensional stability and reducing post-production shrinkage in garments. Heat setting is primarily applied to synthetic fibers like polyester and nylon, stabilizing their shape and improving wrinkle resistance through controlled exposure to high temperatures. Both processes enhance fabric performance by targeting different fiber types and are critical for producing high-quality textiles with consistent fit and appearance.

Choosing the Right Process: Factors to Consider

Choosing between sanforizing and heat setting depends on fabric type, desired dimensional stability, and end-use requirements. Sanforizing is ideal for cotton and woven fabrics that require shrinkage control, while heat setting suits synthetic fibers needing shape retention and wrinkle resistance. Understanding your fabric's composition and performance needs ensures you select the right process to maintain quality and maximize product longevity.

Sanforizing vs Heat setting Infographic

libmatt.com

libmatt.com