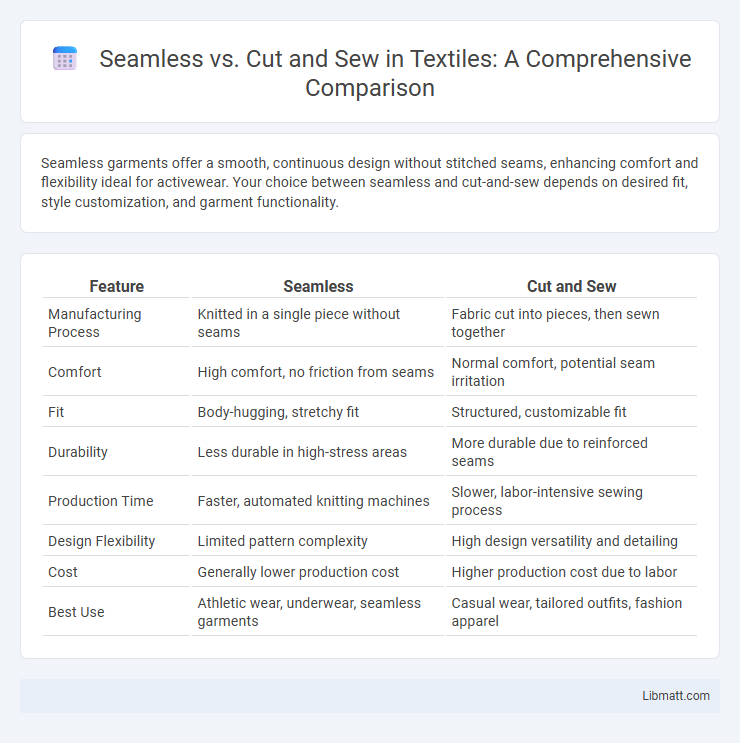

Seamless garments offer a smooth, continuous design without stitched seams, enhancing comfort and flexibility ideal for activewear. Your choice between seamless and cut-and-sew depends on desired fit, style customization, and garment functionality.

Table of Comparison

| Feature | Seamless | Cut and Sew |

|---|---|---|

| Manufacturing Process | Knitted in a single piece without seams | Fabric cut into pieces, then sewn together |

| Comfort | High comfort, no friction from seams | Normal comfort, potential seam irritation |

| Fit | Body-hugging, stretchy fit | Structured, customizable fit |

| Durability | Less durable in high-stress areas | More durable due to reinforced seams |

| Production Time | Faster, automated knitting machines | Slower, labor-intensive sewing process |

| Design Flexibility | Limited pattern complexity | High design versatility and detailing |

| Cost | Generally lower production cost | Higher production cost due to labor |

| Best Use | Athletic wear, underwear, seamless garments | Casual wear, tailored outfits, fashion apparel |

Introduction to Seamless and Cut and Sew Techniques

Seamless technology utilizes advanced knitting machines to create garments without stitched seams, enhancing comfort and fit for activewear and lingerie. Cut and sew involves fabric panels being cut and stitched together, allowing for greater customization in design, pattern, and material combinations. Your choice between seamless and cut and sew can impact manufacturing time, garment durability, and aesthetic detail.

Understanding Seamless Garment Construction

Seamless garment construction utilizes advanced knitting technology to create clothes without traditional seams, enhancing comfort and flexibility by reducing friction and potential irritation. In contrast, cut and sew method involves stitching fabric pieces together, allowing for detailed customization and complex designs but may result in visible seams and less stretchability. Understanding these techniques is essential for selecting performance wear, as seamless garments offer superior fit and durability for active lifestyles.

Exploring Cut and Sew Manufacturing

Cut and sew manufacturing involves individually cutting fabric pieces before stitching them together, enabling detailed customization and complex garment designs. This method allows for precise pattern placement, fabric mixing, and size adjustments, making it ideal for high-quality, tailored apparel. Unlike seamless technology, cut and sew offers flexibility in materials and finishes, supporting diverse fashion demands.

Key Differences Between Seamless and Cut and Sew

Seamless garments are created through advanced knitting technology that produces a single, continuous piece of fabric without stitched seams, offering enhanced comfort and flexibility. Cut and sew involves cutting individual fabric pieces and stitching them together, allowing for greater customization in design, fit, and fabric combinations. Understanding these key differences helps you choose between the streamlined fit of seamless apparel or the tailored construction of cut and sew clothing.

Advantages of Seamless Apparel

Seamless apparel offers superior comfort and flexibility due to the absence of seams that can cause irritation or chafing during physical activity. The manufacturing process, often involving circular knitting technology, enhances durability and provides a sleek, form-fitting design that adapts to the body's contours. This method reduces fabric waste and production time, making seamless garments an eco-friendly and cost-effective alternative to traditional cut and sew apparel.

Benefits of Cut and Sew Garments

Cut and sew garments offer superior customization and precise fit, allowing designers to create unique patterns and tailor each piece to specific measurements. This method enhances fabric utilization and durability, resulting in high-quality finishes and longer-lasting garments. Your wardrobe benefits from the craftsmanship and distinct style that cut and sew techniques provide over seamless production.

Performance and Comfort Comparison

Seamless garments offer superior comfort by minimizing friction and reducing chafing, making them ideal for high-performance activities and extended wear. Cut and sew construction allows for precise tailoring and durability, providing better support and shape retention in demanding sports or activities. Performance-wise, seamless designs excel in flexibility and stretch, while cut and sew garments offer enhanced structural integrity and long-lasting fit.

Sustainability and Environmental Impact

Seamless manufacturing reduces fabric waste by utilizing computerized knitting technology that creates garments in a single piece, minimizing material offcuts common in cut and sew methods. Cut and sew processes often generate more textile scraps and require multiple production stages, leading to higher energy consumption and increased carbon emissions. Sustainable brands prefer seamless techniques for its efficiency in material use and lower environmental footprint, advancing eco-friendly fashion initiatives.

Popular Applications in Fashion and Sportswear

Seamless technology is widely used in athletic wear and performance apparel for its ability to enhance comfort, flexibility, and moisture management without chafing or irritation. Cut and sew methods remain popular in fashion for creating structured garments with intricate designs, allowing precise control over fabric patterns and textures. Both techniques cater to specific market demands, with seamless favored in activewear and cut and sew dominating high-end and casual fashion sectors.

Choosing the Right Method for Your Clothing Line

Seamless garments offer a smooth, comfortable fit with minimal irritation, making them ideal for activewear and athleisure brands prioritizing comfort and flexibility. Cut and sew methods provide greater customization, allowing you to create unique patterns, shapes, and tailored fits, perfect for fashion-forward clothing lines seeking distinct, high-quality designs. Evaluating your brand's target market, design complexity, and production scale helps determine whether seamless efficiency or cut and sew versatility best suits your clothing line's vision.

Seamless vs Cut and sew Infographic

libmatt.com

libmatt.com