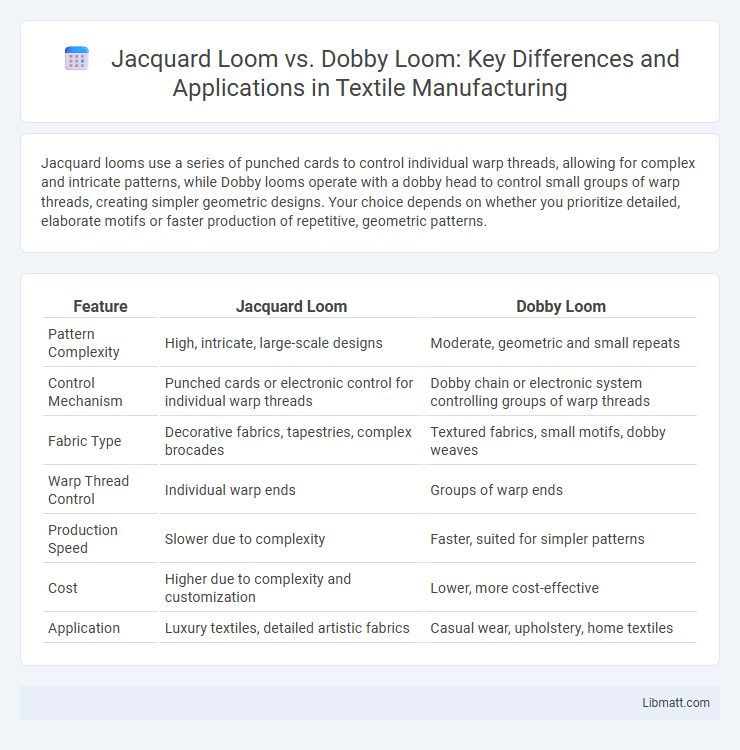

Jacquard looms use a series of punched cards to control individual warp threads, allowing for complex and intricate patterns, while Dobby looms operate with a dobby head to control small groups of warp threads, creating simpler geometric designs. Your choice depends on whether you prioritize detailed, elaborate motifs or faster production of repetitive, geometric patterns.

Table of Comparison

| Feature | Jacquard Loom | Dobby Loom |

|---|---|---|

| Pattern Complexity | High, intricate, large-scale designs | Moderate, geometric and small repeats |

| Control Mechanism | Punched cards or electronic control for individual warp threads | Dobby chain or electronic system controlling groups of warp threads |

| Fabric Type | Decorative fabrics, tapestries, complex brocades | Textured fabrics, small motifs, dobby weaves |

| Warp Thread Control | Individual warp ends | Groups of warp ends |

| Production Speed | Slower due to complexity | Faster, suited for simpler patterns |

| Cost | Higher due to complexity and customization | Lower, more cost-effective |

| Application | Luxury textiles, detailed artistic fabrics | Casual wear, upholstery, home textiles |

Introduction to Jacquard Looms and Dobby Looms

Jacquard looms use a series of punched cards or digital controls to individually raise each warp thread, enabling complex, highly detailed patterns in textile weaving. Dobby looms control small groups of warp threads with a dobby mechanism, allowing for simpler geometric patterns and faster production. Your choice between the two depends on the intricacy of the design and the efficiency required for fabric manufacturing.

Historical Development and Evolution

The Jacquard loom, invented by Joseph Marie Jacquard in 1804, revolutionized textile manufacturing with its ability to produce complex patterns using punched cards, marking a significant advancement over traditional handlooms. The Dobby loom, developed later in the 19th century, introduced a mechanical system for controlling multiple harnesses, enabling the creation of smaller, repetitive geometric patterns more efficiently. Your understanding of these looms highlights how the Jacquard loom's programmable technology laid the groundwork for modern automated weaving, while the Dobby loom optimized fabric design for mass production with simpler patterns.

Basic Working Principles

The Jacquard loom operates using a series of punched cards or digital controls that individually lift each warp thread, enabling highly intricate and complex patterns to be woven with precision. In contrast, the Dobby loom manipulates groups of warp threads through a dobby mechanism to create geometric patterns, allowing faster production but with less detailed designs. Your choice between these looms depends on the complexity and scale of the textile patterns you wish to produce.

Key Components Comparison

The Jacquard loom features a punch card mechanism that controls individual warp threads, enabling complex patterns with high precision. In contrast, the Dobby loom uses a dobby head to manipulate groups of warp threads, allowing for simpler geometric designs and faster setup times. Your choice between the two depends on the complexity of patterns and production speed requirements.

Types of Patterns Produced

Jacquard looms excel at producing highly intricate and complex patterns, including detailed pictorial designs and elaborate brocades, due to their use of individual hook control for each warp thread. Dobby looms are better suited for creating geometric and repetitive patterns, such as stripes, checks, and simple motifs, leveraging a limited number of harnesses to control groups of warp threads simultaneously. The Jacquard loom's capability for unlimited pattern complexity contrasts with the Dobby loom's efficiency in executing less detailed, structured designs.

Fabric Variety and Applications

Jacquard looms excel in creating intricate, large-scale patterns with high design complexity, making them ideal for producing detailed brocades, tapestries, and fine upholstery fabrics. Dobby looms specialize in smaller, geometric patterns and textures, offering versatility for fabrics like shirting, lightweight upholstery, and home textiles. Your choice between the two will depend on the desired fabric variety and the specific applications required for the final product.

Efficiency and Production Speed

The Jacquard loom excels in producing complex, intricate patterns with high precision but operates at a slower production speed due to the detailed control of individual warp threads. The Dobby loom, while limited to simpler geometric patterns, offers greater efficiency and faster weaving speeds by controlling groups of warp threads rather than individual ones. Manufacturers prioritize dobby looms for mass production of less complex fabrics, whereas jacquard looms are preferred for high-quality, detailed textile designs despite longer cycle times.

Cost and Maintenance Factors

Jacquard looms generally incur higher initial costs due to their complex mechanisms and electronic components, while Dobby looms are more affordable and simpler to install. Maintenance expenses for Jacquard looms tend to be greater because of frequent calibration and specialized parts, whereas Dobby looms require less frequent upkeep and use more standardized components. Cost-efficiency in long-term operations often favors Dobby looms for smaller textile productions, whereas Jacquard looms justify their expense in high-complexity fabric designs.

Market Trends and Industrial Usage

The Jacquard loom dominates luxury textile markets due to its ability to produce intricate, large-scale patterns ideal for high-end fashion and upholstery fabrics, driving strong demand in premium segments. The Dobby loom is favored in mass production settings for its efficiency in creating small geometric patterns, supporting fast turnaround times in apparel and home textile industries. Market trends show increasing integration of computerized controls in both looms, enhancing precision and expanding industrial applications across global textile manufacturing hubs.

Choosing the Right Loom for Your Needs

Choosing the right loom depends on the complexity of your weaving patterns and production scale. Jacquard looms excel in creating detailed, intricate designs by controlling each warp thread individually, ideal for highly complex textiles. Your choice should balance design complexity and budget, with dobby looms offering efficiency for simpler, repetitive patterns at lower production costs.

Jacquard loom vs Dobby loom Infographic

libmatt.com

libmatt.com