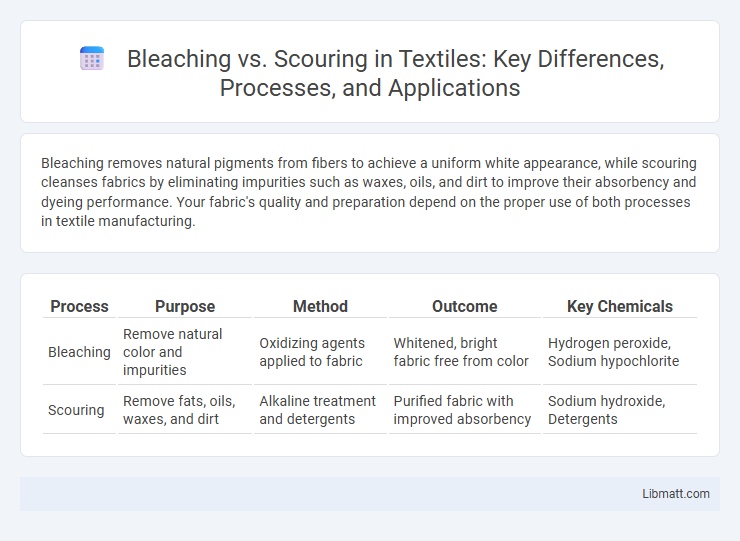

Bleaching removes natural pigments from fibers to achieve a uniform white appearance, while scouring cleanses fabrics by eliminating impurities such as waxes, oils, and dirt to improve their absorbency and dyeing performance. Your fabric's quality and preparation depend on the proper use of both processes in textile manufacturing.

Table of Comparison

| Process | Purpose | Method | Outcome | Key Chemicals |

|---|---|---|---|---|

| Bleaching | Remove natural color and impurities | Oxidizing agents applied to fabric | Whitened, bright fabric free from color | Hydrogen peroxide, Sodium hypochlorite |

| Scouring | Remove fats, oils, waxes, and dirt | Alkaline treatment and detergents | Purified fabric with improved absorbency | Sodium hydroxide, Detergents |

Introduction to Bleaching and Scouring

Bleaching and scouring are essential pre-treatment processes in textile manufacturing that enhance fabric quality and prepare materials for dyeing or finishing. Scouring removes natural impurities such as wax, pectin, and oils from fibers, improving absorbency and cleanliness. Bleaching further whitens and brightens fabrics by breaking down colored substances, ensuring a pure, uniform surface for your desired textile applications.

Definition of Bleaching

Bleaching is a chemical process that removes natural color and impurities from fibers, yarns, or fabrics to achieve a uniform, white appearance essential for further textile processing. It typically involves agents like hydrogen peroxide or chlorine-based compounds, which break down unwanted pigments and residues without damaging the material's integrity. Your textile products benefit from bleaching by gaining enhanced brightness and improved dyeing quality in subsequent finishing steps.

Definition of Scouring

Scouring is a chemical and mechanical process used in textile manufacturing to remove natural impurities such as oils, waxes, and pectins from raw fibers, making them clean and absorbent. Unlike bleaching, which targets the removal or lightening of natural color and stains, scouring primarily prepares the fabric for subsequent treatments by enhancing its cleanliness and wettability. This essential step ensures that fibers are free from contaminants, improving dye uptake and overall fabric quality.

Key Differences Between Bleaching and Scouring

Bleaching removes natural pigments and impurities to whiten textiles, while scouring eliminates oils, waxes, and non-fibrous substances to prepare the fabric for further processing. Scouring improves fabric absorbency and cleanliness, whereas bleaching enhances brightness and color uniformity. Your textile processing sequence relies on these distinct steps to achieve optimal fabric quality.

Purpose and Importance in Textile Processing

Bleaching removes natural color and impurities from fibers to achieve a uniform white base essential for consistent dyeing and printing, while scouring eliminates oils, waxes, and pectins to enhance fiber absorbency and fabric whiteness. Both processes improve fabric quality and ensure effective subsequent chemical treatments in textile manufacturing. Optimizing bleaching and scouring increases fabric cleanliness, dye uptake, and final product durability.

Chemical Agents Used in Bleaching and Scouring

Bleaching involves chemical agents like hydrogen peroxide, sodium hypochlorite, and chlorine dioxide to remove natural color and impurities from textiles, enhancing whiteness and brightness. Scouring utilizes alkaline substances such as sodium hydroxide and detergents to eliminate oils, waxes, and pectins, preparing the fabric for further processing. Your choice between these treatments depends on the fabric type and desired end-use, as each chemical agent targets specific impurities for optimal textile preparation.

Process Steps: Bleaching vs Scouring

Bleaching involves treating textiles with oxidizing agents like hydrogen peroxide to remove natural color and impurities, enhancing fabric whiteness and brightness. Scouring uses alkaline solutions such as sodium hydroxide to remove fats, waxes, and pectins from raw fibers, preparing the fabric for dyeing or finishing. Both processes are critical in textile manufacturing, with scouring focusing on impurity removal and bleaching aiming to achieve desired whiteness.

Effects on Fabric Quality and Appearance

Bleaching removes natural color and impurities from fabric, resulting in a brighter, more uniform appearance but may weaken fibers if overused, affecting durability. Scouring eliminates oils, waxes, and contaminants, enhancing fabric absorbency and smoothness without significantly compromising strength or color uniformity. Your choice between bleaching and scouring impacts fabric quality by balancing clarity and structural integrity according to textile requirements.

Environmental Impact Comparison

Bleaching and scouring both prepare textiles, but their environmental impacts differ significantly. Bleaching often involves chlorine-based chemicals that can produce harmful effluents, whereas scouring typically uses caustic soda and produces alkaline wastewater requiring proper treatment. Your choice between these processes can affect water pollution levels and ecological toxicity, with scouring generally considered less hazardous when managed correctly.

Conclusion: Choosing the Right Process

Choosing the right textile treatment depends on the fabric type and desired end-use; bleaching removes natural pigments for a whiter appearance, while scouring eliminates impurities like oils and waxes for better dye absorption. Your selection should consider the fabric's sensitivity and the final product quality requirements to ensure optimal results. Proper evaluation of material composition and processing goals guarantees that either bleaching or scouring enhances fabric performance effectively.

Bleaching vs Scouring Infographic

libmatt.com

libmatt.com