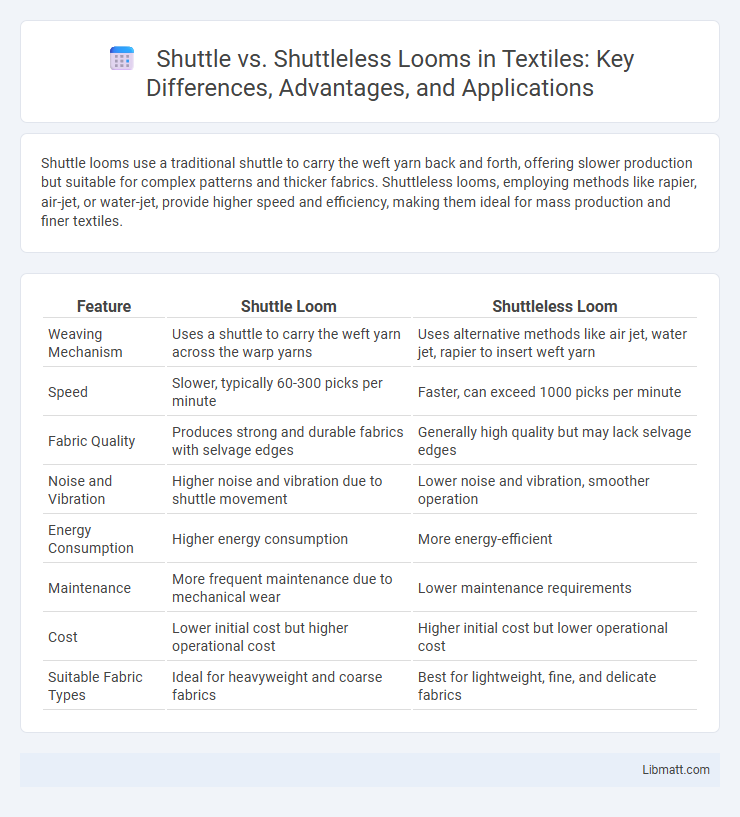

Shuttle looms use a traditional shuttle to carry the weft yarn back and forth, offering slower production but suitable for complex patterns and thicker fabrics. Shuttleless looms, employing methods like rapier, air-jet, or water-jet, provide higher speed and efficiency, making them ideal for mass production and finer textiles.

Table of Comparison

| Feature | Shuttle Loom | Shuttleless Loom |

|---|---|---|

| Weaving Mechanism | Uses a shuttle to carry the weft yarn across the warp yarns | Uses alternative methods like air jet, water jet, rapier to insert weft yarn |

| Speed | Slower, typically 60-300 picks per minute | Faster, can exceed 1000 picks per minute |

| Fabric Quality | Produces strong and durable fabrics with selvage edges | Generally high quality but may lack selvage edges |

| Noise and Vibration | Higher noise and vibration due to shuttle movement | Lower noise and vibration, smoother operation |

| Energy Consumption | Higher energy consumption | More energy-efficient |

| Maintenance | More frequent maintenance due to mechanical wear | Lower maintenance requirements |

| Cost | Lower initial cost but higher operational cost | Higher initial cost but lower operational cost |

| Suitable Fabric Types | Ideal for heavyweight and coarse fabrics | Best for lightweight, fine, and delicate fabrics |

Introduction to Loom Technologies

Shuttle looms use a traditional shuttle to carry the weft yarn through the warp threads, offering a slower weaving process but producing durable, high-quality fabric. Shuttleless looms, including rapier, air-jet, and water-jet types, use advanced technologies to insert the weft yarn more efficiently, enabling higher speeds and greater fabric variety. Modern textile manufacturing increasingly favors shuttleless looms due to their faster production rates, reduced noise levels, and lower maintenance costs.

Overview of Shuttle Looms

Shuttle looms utilize a shuttle to carry the weft yarn back and forth through the warp yarns, producing tightly woven fabrics with high durability. These looms are known for their slower weaving speed but offer superior fabric quality and versatility, especially in producing thicker and more complex textiles. Shuttle looms are widely used in applications requiring strong, heavy fabrics such as denim, upholstery, and canvas.

Overview of Shuttleless Looms

Shuttleless looms revolutionize fabric production by eliminating the traditional shuttle mechanism, using alternative methods like rapier, air-jet, or projectile to insert the weft yarn. These looms significantly increase weaving speed, reduce noise, and lower maintenance costs compared to traditional shuttle looms. Your manufacturing efficiency benefits from improved fabric quality and the ability to handle a wide range of yarn types with greater precision.

Key Differences Between Shuttle and Shuttleless Looms

Shuttle looms use a shuttle to carry the weft yarn back and forth across the warp, producing fabric at slower speeds with more noise and mechanical wear. Shuttleless looms, such as rapier, projectile, air-jet, and water-jet looms, eliminate the shuttle mechanism, enabling faster production, smoother operation, and reduced maintenance. The main differences lie in weaving speed, efficiency, noise levels, and suitability for various fabric types and production scales.

Weaving Speed and Efficiency Comparison

Shuttleless looms operate at significantly higher weaving speeds, often reaching up to 1,500 picks per minute compared to traditional shuttle looms, which average around 60 to 200 picks per minute. The efficiency of shuttleless looms is enhanced by reduced yarn breakage and less frequent bobbin changes, leading to continuous operation and minimal downtime. This speed and operational efficiency make shuttleless looms ideal for large-scale textile production with faster turnaround times.

Fabric Quality and Versatility

Shuttle looms produce fabrics with a tighter weave and greater density, resulting in higher-quality textiles ideal for heavy-duty and traditional patterns. Shuttleless looms, such as air-jet and rapier looms, offer enhanced versatility by enabling faster production speeds and accommodating a wider range of fabric types and designs. Your choice between these two weaving methods will impact fabric durability, texture, and the complexity of patterns achievable.

Energy Consumption and Maintenance

Shuttleless looms consume significantly less energy than traditional shuttle looms due to their faster weaving speed and more efficient mechanical design, reducing operational costs. Maintenance requirements for shuttleless looms are generally lower, as they have fewer moving parts and reduced wear and tear compared to shuttle looms, which need frequent servicing to handle the heavy shuttle movement. Choosing a shuttleless loom can optimize your production efficiency by minimizing both energy consumption and maintenance downtime.

Cost Considerations for Manufacturers

Shuttle looms typically incur higher initial costs due to complex mechanical parts and slower production rates, impacting overall manufacturing expenses. Shuttleless looms, favored for their efficiency and speed, offer lower operational costs and reduced maintenance, making them more cost-effective for large-scale fabric production. Choosing the right loom can optimize your manufacturing budget by balancing upfront investment with long-term productivity gains.

Environmental Impact of Loom Types

Shuttleless looms significantly reduce energy consumption and waste compared to traditional shuttle looms, resulting in a lower environmental footprint. Shuttleless weaving technology minimizes noise pollution and decreases the use of lubricants, promoting a cleaner manufacturing process. Your choice of loom type influences sustainability outcomes, with shuttleless looms offering more eco-friendly production benefits.

Future Trends in Loom Technology

Shuttleless looms are gaining traction due to their higher speed, efficiency, and lower maintenance compared to traditional shuttle looms, which rely on a shuttle to carry the weft yarn. Future trends in loom technology emphasize automation, digital integration, and energy-efficient designs, enhancing precision and reducing operational costs. Your textile production can benefit from adopting next-generation shuttleless looms that incorporate IoT sensors and AI for real-time monitoring and adaptive control.

Shuttle vs Shuttleless loom Infographic

libmatt.com

libmatt.com