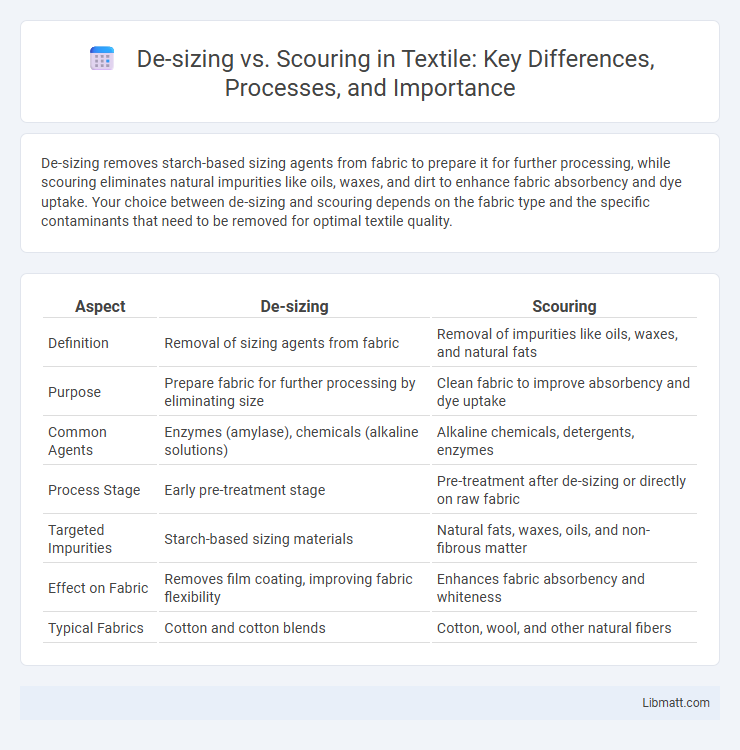

De-sizing removes starch-based sizing agents from fabric to prepare it for further processing, while scouring eliminates natural impurities like oils, waxes, and dirt to enhance fabric absorbency and dye uptake. Your choice between de-sizing and scouring depends on the fabric type and the specific contaminants that need to be removed for optimal textile quality.

Table of Comparison

| Aspect | De-sizing | Scouring |

|---|---|---|

| Definition | Removal of sizing agents from fabric | Removal of impurities like oils, waxes, and natural fats |

| Purpose | Prepare fabric for further processing by eliminating size | Clean fabric to improve absorbency and dye uptake |

| Common Agents | Enzymes (amylase), chemicals (alkaline solutions) | Alkaline chemicals, detergents, enzymes |

| Process Stage | Early pre-treatment stage | Pre-treatment after de-sizing or directly on raw fabric |

| Targeted Impurities | Starch-based sizing materials | Natural fats, waxes, oils, and non-fibrous matter |

| Effect on Fabric | Removes film coating, improving fabric flexibility | Enhances fabric absorbency and whiteness |

| Typical Fabrics | Cotton and cotton blends | Cotton, wool, and other natural fibers |

Introduction to De-sizing and Scouring

De-sizing removes starch-based adhesives from fabric, preparing it for subsequent treatments by eliminating impurities that hinder dye absorption. Scouring further purifies the textile by extracting natural waxes, oils, and non-fibrous matter, enhancing fabric wettability and improving dye uniformity. Your fabric's quality and dyeing results depend heavily on the precise execution of both de-sizing and scouring processes.

Understanding Textile Preparation Processes

De-sizing removes starch-based sizing agents from woven fabrics, improving fabric absorbency for dyeing and finishing, while scouring eliminates natural impurities such as oils, waxes, and pectins to enhance wetting and uniformity. Both processes are critical in textile preparation, ensuring optimal fabric quality and performance before subsequent treatments. Effective de-sizing and scouring significantly influence dye uptake and fabric texture, impacting the final product's durability and appearance.

What is De-sizing?

De-sizing is a textile process that removes the sizing agents, usually starch or synthetic polymers, applied to yarns to strengthen them during weaving. This step is essential to prepare the fabric for further treatments by eliminating residues that can interfere with dyeing and finishing processes. Understanding the difference between de-sizing and scouring helps optimize fabric quality and ensure your textiles achieve the desired softness and cleanliness.

What is Scouring?

Scouring is a crucial textile processing technique used to remove natural oils, waxes, dirt, and impurities from raw fibers such as cotton or wool to enhance fabric absorbency and dye uptake. This chemical and mechanical treatment involves alkaline solutions that effectively cleanse the fibers without damaging their structure. Unlike de-sizing, which specifically targets the removal of sizing agents applied during weaving, scouring focuses on purifying the fibers at a deeper level to prepare them for subsequent finishing processes.

Key Differences Between De-sizing and Scouring

De-sizing involves removing starch-based sizing agents from fabric to prepare it for subsequent textile processing, while scouring eliminates natural impurities such as waxes, oils, and pectins to enhance fabric absorbency. The key difference lies in the purpose and substances removed: de-sizing targets synthetic or applied chemicals, whereas scouring focuses on natural contaminants. Process parameters such as temperature, chemicals used, and duration also differ, with de-sizing typically using enzymes or alkaline treatments and scouring employing alkalis and surfactants.

Purposes and Applications in Textile Processing

De-sizing removes starch-based sizing agents from yarns to improve absorbency and prepare fabrics for further treatments, while scouring eliminates natural oils, waxes, and impurities to enhance fabric cleanliness and dye receptivity. De-sizing is primarily applied to woven fabrics to prevent uneven dyeing, whereas scouring is essential for both woven and knitted textiles to achieve uniform coloration and fabric softness. Your textile processing efficiency depends on selecting the appropriate method to optimize fabric quality and readiness for subsequent finishing processes.

Chemicals and Methods Used in Each Process

De-sizing involves the removal of size agents such as starch, waxes, and synthetic polymers using enzymes like amylase or chemical agents including acids and alkalis to break down these starch-based compounds. Scouring employs stronger alkaline chemicals, primarily sodium hydroxide, combined with surfactants and wetting agents to eliminate natural impurities like oils, fats, and waxes from fibers, enhancing fabric absorbency. Enzymatic de-sizing methods are preferred for eco-friendly processing, whereas scouring relies on thermal treatments and controlled alkali concentration to effectively clean the textile surface.

Impact on Fabric Quality

De-sizing removes starch or sizing agents from woven fabrics, ensuring smoothness and preventing defects during dyeing, thus preserving fabric integrity and minimizing yarn damage. Scouring eliminates impurities such as oils, waxes, and natural fats from fibers, enhancing fabric absorbency and achieving uniform dye uptake while improving softness and brightness. Both processes are critical for fabric quality, but scouring has a more profound effect on fabric hand feel and dye uniformity, whereas de-sizing mainly targets surface cleanliness and fabric smoothness.

Environmental Considerations

De-sizing reduces the environmental impact by removing starch-based sizing agents, resulting in lower water and energy consumption compared to scouring. Scouring involves harsh chemicals and alkalis that generate higher levels of wastewater pollution and require extensive treatment before disposal. Effective selection between de-sizing and scouring processes significantly influences the sustainability of textile processing by minimizing chemical usage and reducing effluent toxicity.

Choosing the Right Process for Your Textile Needs

Selecting between de-sizing and scouring depends on the fabric type and desired finish, as de-sizing removes starch and adhesives used in weaving, while scouring eliminates oils, waxes, and impurities. For cotton and linen, scouring is essential to achieve a clean, absorbent surface, whereas synthetic or blended fabrics often require targeted de-sizing to preserve fabric integrity. Evaluating fiber composition, production goals, and environmental impact ensures the right textile preparation process, optimizing quality and performance.

De-sizing vs Scouring Infographic

libmatt.com

libmatt.com