A sinker loop forms when the loop sinks below the fabric surface, creating a less visible, tension-relaxed stitch ideal for fine and delicate knits. Your choice between sinker and knit loops affects fabric texture and elasticity, with knit loops appearing more prominent and offering greater stretch.

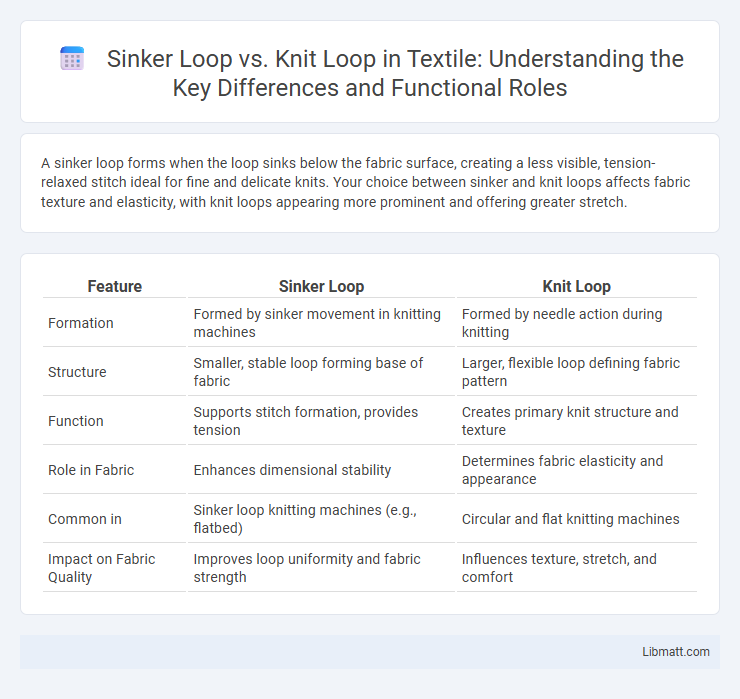

Table of Comparison

| Feature | Sinker Loop | Knit Loop |

|---|---|---|

| Formation | Formed by sinker movement in knitting machines | Formed by needle action during knitting |

| Structure | Smaller, stable loop forming base of fabric | Larger, flexible loop defining fabric pattern |

| Function | Supports stitch formation, provides tension | Creates primary knit structure and texture |

| Role in Fabric | Enhances dimensional stability | Determines fabric elasticity and appearance |

| Common in | Sinker loop knitting machines (e.g., flatbed) | Circular and flat knitting machines |

| Impact on Fabric Quality | Improves loop uniformity and fabric strength | Influences texture, stretch, and comfort |

Introduction to Sinker Loop and Knit Loop

Sinker Loop and Knit Loop represent distinct knitting techniques that influence fabric texture and elasticity. The Sinker Loop, formed as the needle sinks below the fabric surface, creates a smoother and more compact stitch pattern favored in tight-knit textiles. In contrast, the Knit Loop emerges when the yarn is drawn through the previous stitch loop on the needle front, producing a more elastic and breathable fabric ideal for garments requiring stretch.

Defining Sinker Loop in Knitting

A sinker loop in knitting is the strand of yarn that lies on the fabric's backside, connecting adjacent loops and forming the underlying structure of the knitted piece. Unlike the knit loop, which creates the visible front stitch, sinker loops provide stability and elasticity to the fabric by linking the rows together. Understanding the function of sinker loops is essential for analyzing stitch formation and fabric behavior in various knitting techniques.

What is a Knit Loop?

A Knit Loop is a type of fishing knot used to securely attach the fishing line to a hook or lure, providing a strong and reliable connection. Compared to a Sinker Loop, which creates a loop for attaching weights, the Knit Loop focuses on maintaining line strength and flexibility, making it ideal for various angling techniques. Understanding the Knit Loop can enhance your fishing experience by ensuring your tackle performs effectively under tension.

Structural Differences Between Sinker Loop and Knit Loop

Sinker loop features a distinct formation where the yarn passes under the sinker bar, creating a tighter, more compact loop structure compared to the knit loop, which forms by intermeshing yarns through the needle hook. The sinker loop's closer connection to the fabric surface results in firmer fabric properties, while knit loops generate a more flexible and open texture due to their loop shape and orientation. These structural differences impact fabric elasticity, durability, and overall hand feel in knitted and woven textiles.

Functional Roles in Fabric Formation

Sinker loops play a critical role in fabric formation by controlling the movement of the sinker bar, which guides the knitting needles to form consistent loop structures essential for fabric stability. Knit loops are the fundamental building blocks of the knitted fabric, created by the needles pulling yarn through previously formed loops to generate the intermeshed pattern. The interaction between sinker loops and knit loops ensures uniform stitch formation, directly impacting fabric strength, elasticity, and texture.

Visual Identification: Sinker vs Knit Loop

The sinker loop is characterized by its tight, uniform appearance blending seamlessly with surrounding stitches, making it easier to spot by its compact and less prominent shape. In contrast, a knit loop displays a more open, elongated structure with a distinctive "V" shape formed by two parallel strands, which stands out clearly in fabric texture. Your ability to visually identify each loop type is essential for precise knitting repairs and pattern recognition.

Impact on Fabric Properties and Texture

Sinker loops create a denser and more stable fabric with a smoother surface, enhancing durability and reducing stretch, ideal for structured textiles. Knit loops produce a softer, more elastic fabric with greater breathability and natural drape, contributing to comfort and flexibility in garments. Your choice between sinker and knit loops directly influences fabric texture, stretchability, and overall wearability, tailoring the material to specific performance needs.

Common Applications in Textile Industry

Sinker loops are widely utilized in the production of rib fabrics and textured knits where elasticity and durability are essential, often featured in sportswear and hosiery. Knit loops form the foundation of most woven textiles, providing strength and stability, making them ideal for apparel, upholstery, and industrial fabrics. Both loop types influence fabric behavior in applications requiring distinct stretch and resilience properties.

Advantages and Limitations of Each Loop

Sinker loops offer better stability and reduced lateral movement in fishing rigs, making them ideal for targeting bottom-dwelling fish. However, sinker loops can increase the risk of line twist and require more skill to tie securely. Knit loops provide greater flexibility and ease of tying, allowing for quicker rig changes but may lack the enhanced stability of sinker loops in strong currents.

Conclusion: Choosing the Right Loop for Your Project

Selecting the appropriate loop between sinker loops and knit loops depends heavily on project requirements such as fabric texture, elasticity, and durability. Sinker loops provide a more stable and less stretchy fabric ideal for structured garments, while knit loops offer greater flexibility and softness suited for casual wear or athletic apparel. Understanding the specific fabric properties needed ensures optimal performance and comfort in the final product.

Sinker loop vs Knit loop Infographic

libmatt.com

libmatt.com