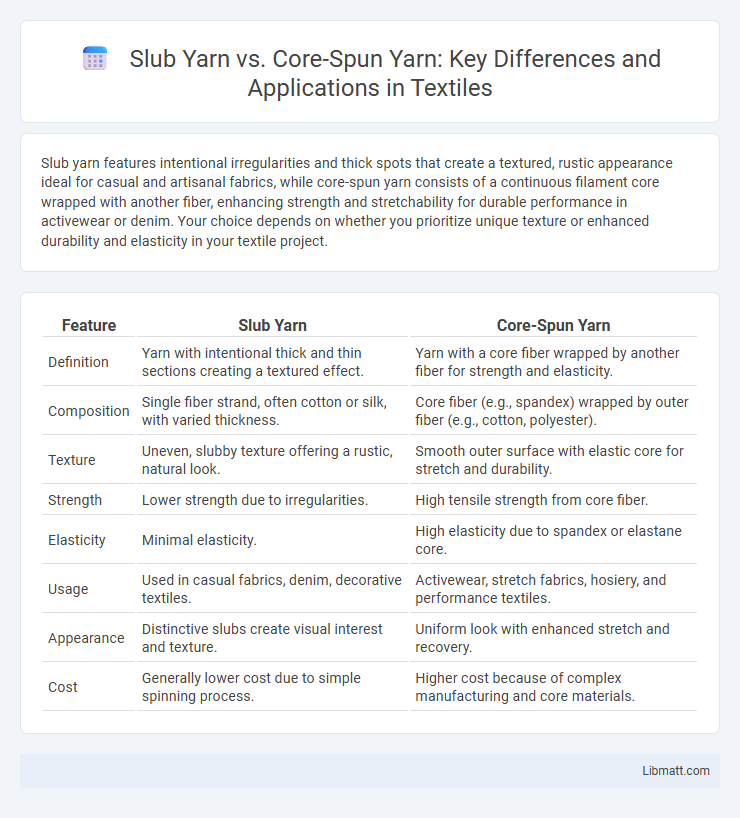

Slub yarn features intentional irregularities and thick spots that create a textured, rustic appearance ideal for casual and artisanal fabrics, while core-spun yarn consists of a continuous filament core wrapped with another fiber, enhancing strength and stretchability for durable performance in activewear or denim. Your choice depends on whether you prioritize unique texture or enhanced durability and elasticity in your textile project.

Table of Comparison

| Feature | Slub Yarn | Core-Spun Yarn |

|---|---|---|

| Definition | Yarn with intentional thick and thin sections creating a textured effect. | Yarn with a core fiber wrapped by another fiber for strength and elasticity. |

| Composition | Single fiber strand, often cotton or silk, with varied thickness. | Core fiber (e.g., spandex) wrapped by outer fiber (e.g., cotton, polyester). |

| Texture | Uneven, slubby texture offering a rustic, natural look. | Smooth outer surface with elastic core for stretch and durability. |

| Strength | Lower strength due to irregularities. | High tensile strength from core fiber. |

| Elasticity | Minimal elasticity. | High elasticity due to spandex or elastane core. |

| Usage | Used in casual fabrics, denim, decorative textiles. | Activewear, stretch fabrics, hosiery, and performance textiles. |

| Appearance | Distinctive slubs create visual interest and texture. | Uniform look with enhanced stretch and recovery. |

| Cost | Generally lower cost due to simple spinning process. | Higher cost because of complex manufacturing and core materials. |

Introduction to Slub Yarn and Core-Spun Yarn

Slub yarn features intentional variations in thickness, creating textured fabric with unique visual interest and tactile appeal. Core-spun yarn consists of a central core fiber wrapped tightly by a different outer fiber, offering enhanced strength, elasticity, and durability. Understanding these distinct yarn constructions helps you select the right material for your textile or garment needs.

Defining Slub Yarn: Characteristics and Production

Slub yarn is characterized by its intentionally irregular thickness, creating textured fabric with unique visual appeal and tactile interest. It is produced by varying the twist or tension during spinning, forming thicker, bumpy sections called slubs along the yarn. Your choice of slub yarn adds distinctiveness to textiles, providing an artisanal, rustic look compared to more uniform yarns like core-spun variants.

What is Core-Spun Yarn? Structure and Creation

Core-spun yarn consists of a central filament core wrapped with staple fibers, combining the strength of synthetic filaments with the natural feel of cotton or other fibers. Its structure features a tightly spun core that provides durability and elasticity, while the outer fibers contribute softness and texture. The creation process involves spinning filament yarn around a core strand, typically using ring or rotor spinning techniques, resulting in enhanced yarn strength and improved fabric performance.

Key Differences Between Slub Yarn and Core-Spun Yarn

Slub yarn features irregular thickness with intentional lumps, creating a textured, uneven fabric surface, while core-spun yarn consists of a continuous filament core wrapped with staple fibers, offering enhanced strength and elasticity. You will find slub yarn ideal for decorative, lightweight textiles, whereas core-spun yarn excels in durability and performance for technical or activewear applications. Key differences lie in their structure, texture, and functional use, influencing fabric appearance and mechanical properties.

Advantages of Using Slub Yarn

Slub yarn offers a unique texture with irregular thickness that enhances fabric aesthetics and adds visual interest to your garments. Its uneven surface provides a natural, artisanal look while maintaining breathability and comfort. This yarn is ideal for creating distinctive designs in casual and fashion-forward textiles.

Benefits of Core-Spun Yarn in Textile Applications

Core-spun yarn offers superior strength and durability compared to slub yarn, making it ideal for high-performance textile applications. Its unique construction, with a core fiber surrounded by staple fibers, enhances elasticity and abrasion resistance, which is essential for activewear and industrial fabrics. Core-spun yarn also provides better uniformity and comfort, improving the overall quality and longevity of the textile products.

Common Uses of Slub Yarn vs Core-Spun Yarn

Slub yarn is commonly used in casual and textured fabrics such as denim, knits, and lightweight outerwear, providing a unique, uneven surface ideal for fashion-forward designs. Core-spun yarn is widely employed in industrial textiles, performance wear, sewing threads, and upholstery due to its enhanced strength, durability, and elasticity from the polyester or nylon core wrapped with cotton or wool fibers. Both yarns serve distinct purposes, with slub yarn emphasizing aesthetic appeal and core-spun yarn focusing on functional performance in diverse applications.

Durability and Performance Comparison

Slub yarn features irregular thickness that creates unique texture but may reduce uniform durability, making it best for fashion fabrics rather than high-stress use. Core-spun yarn combines a strong synthetic core with natural fibers, enhancing tensile strength, abrasion resistance, and overall performance in demanding applications. For long-lasting textiles requiring consistent durability, your best choice is core-spun yarn, which outperforms slub yarn in industrial and activewear settings.

Aesthetic and Textural Differences

Slub yarn features irregular thick and thin sections, creating a natural, textured look with a slightly uneven surface that adds visual interest and a rustic aesthetic to fabrics. Core-spun yarn, constructed with a strong central core wrapped in fibers, offers a more uniform texture and consistent appearance, enhancing durability while maintaining a smooth hand feel. Your choice between these yarns influences the fabric's tactile experience and visual complexity, with slub yarn emphasizing uniqueness and core-spun yarn prioritizing strength and evenness.

Choosing Between Slub Yarn and Core-Spun Yarn

Choosing between slub yarn and core-spun yarn depends on the desired fabric texture and functionality; slub yarn offers irregular thickness for a textured, natural look, ideal for casual or decorative textiles, while core-spun yarn combines a strong filament core with wrapping fibers, providing enhanced strength and durability, suitable for performance and industrial applications. Slub yarn's unique thickness variations create visual interest and softness, whereas core-spun yarn's construction optimizes yarn strength and resistance to abrasion. Selecting the right yarn requires assessing end-use requirements such as aesthetic appeal, fabric performance, and production techniques.

Slub Yarn vs Core-Spun Yarn Infographic

libmatt.com

libmatt.com