A tenter frame is a mechanical device used in textile manufacturing to stretch and dry fabric by holding it taut with clips along its edges, ensuring uniform width and preventing shrinkage. The stenter frame performs the same essential function, with "stenter" often used interchangeably in the industry to describe equipment that sets fabric dimensions and finishes materials during processing.

Table of Comparison

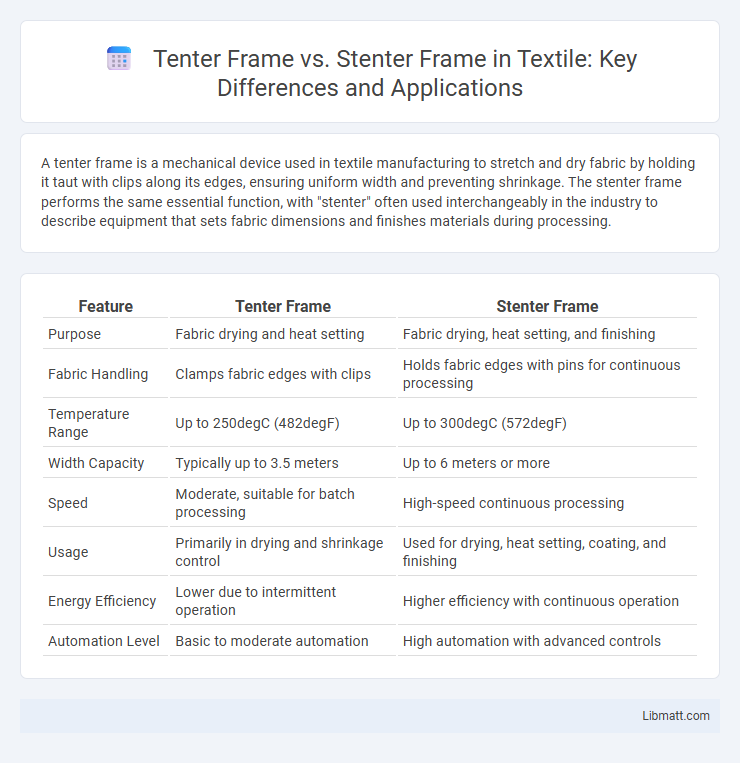

| Feature | Tenter Frame | Stenter Frame |

|---|---|---|

| Purpose | Fabric drying and heat setting | Fabric drying, heat setting, and finishing |

| Fabric Handling | Clamps fabric edges with clips | Holds fabric edges with pins for continuous processing |

| Temperature Range | Up to 250degC (482degF) | Up to 300degC (572degF) |

| Width Capacity | Typically up to 3.5 meters | Up to 6 meters or more |

| Speed | Moderate, suitable for batch processing | High-speed continuous processing |

| Usage | Primarily in drying and shrinkage control | Used for drying, heat setting, coating, and finishing |

| Energy Efficiency | Lower due to intermittent operation | Higher efficiency with continuous operation |

| Automation Level | Basic to moderate automation | High automation with advanced controls |

Introduction to Tenter Frame and Stenter Frame

Tenter frames and stenter frames are industrial textile drying machines designed to maintain fabric width while drying and heat-setting. Tenter frames utilize adjustable clips or pins to hold the fabric edges, ensuring dimensional stability and smoothness during processing. Stenter frames often include more advanced features such as temperature control zones and fabric stretching capabilities, optimizing the fabric's final texture and quality.

Historical Development of Tenter and Stenter Frames

Tenter and stenter frames evolved from early textile finishing technologies, with the tenter frame originating in the 18th century as a tool to stretch woven fabrics to maintain dimensions during drying. The stenter frame advanced this concept by incorporating heated pins and automated mechanisms in the 20th century, enhancing fabric drying speed and dimensional control for industrial textile processing. These innovations significantly improved fabric quality and efficiency in textile manufacturing.

Key Differences Between Tenter Frame and Stenter Frame

Tenter frames and stenter frames are essential textile machines used for fabric drying and finishing, with key differences in their mechanism and applications. Tenter frames use chain clips to hold fabric edges firmly during heat-setting, ensuring precise dimensional control, while stenter frames often utilize pin clips or pins, suitable for lighter fabrics. Your choice depends on fabric type, processing requirements, and desired end-use stability.

Working Principle of Tenter Frame

The working principle of a Tenter frame involves gripping fabric edges with clips and stretching it uniformly while passing through a series of heated chambers to achieve precise dimensional stability. This method ensures consistent width and fabric tension, preventing shrinkage during drying processes. Understanding this working principle helps optimize your textile finishing operations for improved fabric quality.

Working Principle of Stenter Frame

The stenter frame operates by gripping the fabric on both edges using adjustable clips or pins, then stretching and drying it under controlled temperature and tension to achieve precise dimensional stability. Heat is applied either through hot air circulation or infrared heaters, enabling the fabric to be dried and thermally set simultaneously, which improves fabric properties such as width consistency and texture. Your choice of a stenter frame influences production efficiency and fabric quality due to its ability to control drying speed and tension accurately.

Advantages and Disadvantages: Tenter Frame vs Stenter Frame

Tenter frames provide precise fabric width control and uniform drying, making them ideal for delicate textiles, but they consume more energy and require higher maintenance compared to stenter frames. Stenter frames offer faster processing speeds and lower operational costs, benefiting large-scale production, though they may cause uneven fabric tension and less accurate width control. Choosing between tenter and stenter frames depends on fabric type, production volume, and quality requirements.

Applications in Textile Processing

Tenter frames and stenter frames are essential in textile processing for fabric drying, heat setting, and finishing, with applications varying by fabric type and desired effect. Tenter frames are primarily used for synthetic and woven fabrics to achieve precise dimensional control and edge finishing, ensuring stability and uniform width. You might choose stenter frames for knit fabrics and delicate textiles where gentle handling and controlled drying improve fabric texture and performance.

Energy Efficiency Comparison

Tenter frames generally offer higher energy efficiency compared to stenter frames due to their precise fabric tension control, which reduces heat loss and drying time. The controlled environment in tenter frames minimizes energy consumption by optimizing airflow and temperature uniformity. For your textile processing needs, using tenter frames can lead to significant energy savings and lower operational costs.

Maintenance and Operational Costs

Tenter frames generally require less frequent maintenance due to their simpler mechanical structure, reducing your overall operational costs. Stenter frames, equipped with heating and stretching mechanisms, demand regular inspection and upkeep to ensure efficient fabric processing, which can increase maintenance expenses. Choosing between the two depends on your specific production needs and budget for ongoing operational costs.

Choosing the Right Frame for Your Textile Operations

Selecting the right frame for textile operations involves understanding the key differences between tenter frames and stenter frames. Tenter frames provide precise fabric width control through clips or pins, ideal for delicate materials requiring uniform stretching during drying and finishing processes. Stenter frames incorporate advanced temperature and tension controls, offering enhanced efficiency for high-volume production with diverse fabric types, ensuring dimensional stability and quality.

Tenter frame vs Stenter frame Infographic

libmatt.com

libmatt.com