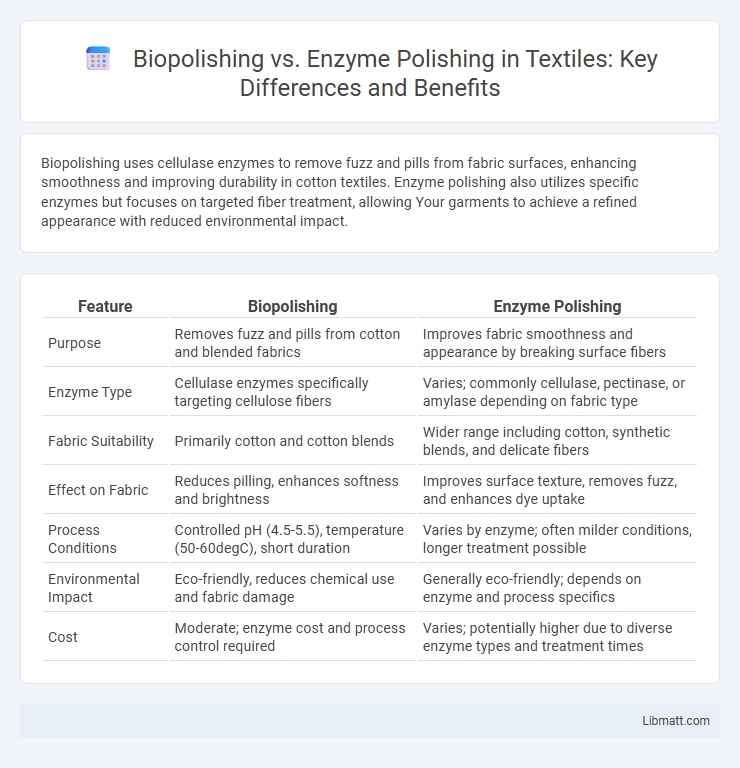

Biopolishing uses cellulase enzymes to remove fuzz and pills from fabric surfaces, enhancing smoothness and improving durability in cotton textiles. Enzyme polishing also utilizes specific enzymes but focuses on targeted fiber treatment, allowing Your garments to achieve a refined appearance with reduced environmental impact.

Table of Comparison

| Feature | Biopolishing | Enzyme Polishing |

|---|---|---|

| Purpose | Removes fuzz and pills from cotton and blended fabrics | Improves fabric smoothness and appearance by breaking surface fibers |

| Enzyme Type | Cellulase enzymes specifically targeting cellulose fibers | Varies; commonly cellulase, pectinase, or amylase depending on fabric type |

| Fabric Suitability | Primarily cotton and cotton blends | Wider range including cotton, synthetic blends, and delicate fibers |

| Effect on Fabric | Reduces pilling, enhances softness and brightness | Improves surface texture, removes fuzz, and enhances dye uptake |

| Process Conditions | Controlled pH (4.5-5.5), temperature (50-60degC), short duration | Varies by enzyme; often milder conditions, longer treatment possible |

| Environmental Impact | Eco-friendly, reduces chemical use and fabric damage | Generally eco-friendly; depends on enzyme and process specifics |

| Cost | Moderate; enzyme cost and process control required | Varies; potentially higher due to diverse enzyme types and treatment times |

Introduction to Biopolishing and Enzyme Polishing

Biopolishing is a textile finishing process that uses enzymes to remove protruding fibers from fabric surfaces, enhancing smoothness and reducing pilling. Enzyme polishing specifically refers to the application of cellulase enzymes targeting cellulose fibers in cotton and other cellulosic fabrics to improve texture and appearance. Both techniques optimize fabric quality by enzymatically refining surface fibers without harsh chemical treatments, promoting sustainability in textile finishing.

Definition and Process Overview

Biopolishing is a textile finishing process that uses cellulose-degrading enzymes to remove fuzz and pills from cotton fabrics, enhancing surface smoothness and fabric strength. Enzyme polishing specifically refers to the application of enzymes like cellulase to break down protruding fibers without damaging the fabric structure, resulting in improved texture and appearance. Both processes involve controlled enzymatic treatments that target fiber protrusions to achieve a cleaner, softer fabric finish.

Key Enzymes Used in Both Techniques

Biopolishing primarily uses cellulase enzymes to remove surface fibers and enhance fabric smoothness, while enzyme polishing employs a broader range of enzymes, including amylases, proteases, and lipases, targeting starch, protein, and fat residues respectively. These enzymes work at specific pH levels and temperatures to optimize fabric appearance and texture without damaging fibers. Your choice between biopolishing and enzyme polishing can depend on the fabric type and desired finish, leveraging the specific enzymatic activity to achieve superior textile quality.

Comparison of Mechanisms: How They Work

Biopolishing uses cellulase enzymes to remove fuzz and pills from cotton fabrics by breaking down the microfibers on the surface, resulting in a smoother and cleaner appearance. Enzyme polishing, often involving proteases or other specific enzymes, targets protein-based fibers or stains, enhancing fabric softness and brightness through selective hydrolysis. Your choice between biopolishing and enzyme polishing depends on the fabric type and desired finish, as each mechanism operates with distinct enzyme-substrate specificity.

Impact on Fabric Quality and Texture

Biopolishing uses cellulase enzymes to remove fuzz and pills from cotton fabrics, resulting in a smoother, softer texture with enhanced sheen and reduced pilling. Enzyme polishing targets the fabric's surface fibers without weakening the main structure, preserving strength while improving hand feel and durability. You can expect biopolishing to refine fabric quality by ensuring a cleaner finish, whereas enzyme polishing balances fabric aesthetics and longevity effectively.

Environmental and Sustainability Considerations

Biopolishing uses natural enzymes to remove surface fibers from fabrics, reducing chemical waste and energy consumption compared to conventional chemical treatments. Enzyme polishing, specifically with cellulases, improves fabric softness and appearance while minimizing water pollution due to its biodegradable nature. Your choice of biopolishing enhances sustainability by promoting eco-friendly textile processing with lower environmental impact.

Cost Efficiency and Industrial Adoption

Biopolishing offers higher cost efficiency due to its ability to simultaneously reduce pilling and improve fabric quality with minimal chemical usage, making it more attractive for large-scale textile manufacturing. Enzyme polishing, while effective, generally incurs higher operational costs because of enzyme specificity and the need for controlled process parameters, limiting its widespread industrial adoption. Textile industries favor biopolishing processes to optimize production costs and enhance fabric durability, driving greater investment and integration in commercial settings.

Common Textile Applications

Biopolishing and enzyme polishing are widely used in the textile industry to enhance fabric appearance and performance. Biopolishing is commonly applied to cotton and cotton-blend fabrics to remove fuzz and pills, improving softness and luster, while enzyme polishing primarily targets denim and wool to achieve color fading and surface smoothness. Both processes are integral to producing high-quality apparel and home textiles with durable, soft finishes.

Limitations and Challenges

Biopolishing faces limitations such as higher costs due to specialized enzymes and sensitivity to fabric type, restricting its application primarily to cellulose fibers like cotton. Enzyme polishing challenges include controlling enzyme activity to prevent fabric damage, as excessive treatment can weaken fibers and reduce fabric strength. Both methods require precise process optimization to balance enhanced fabric finish with maintaining textile durability and cost-efficiency.

Future Trends in Textile Finishing Technologies

Biopolishing and enzyme polishing represent cutting-edge advancements in textile finishing technologies, leveraging biodegradability and eco-friendly enzymes to enhance fabric quality while reducing environmental impact. Future trends emphasize integrating nanotechnology and bioengineering to develop more precise, cost-effective enzyme treatments tailored for diverse fiber types, promoting sustainable production. These innovations aim to minimize chemical usage, enhance fabric softness, durability, and aesthetic appeal, aligning textile finishing processes with global sustainability goals.

Biopolishing vs Enzyme polishing Infographic

libmatt.com

libmatt.com