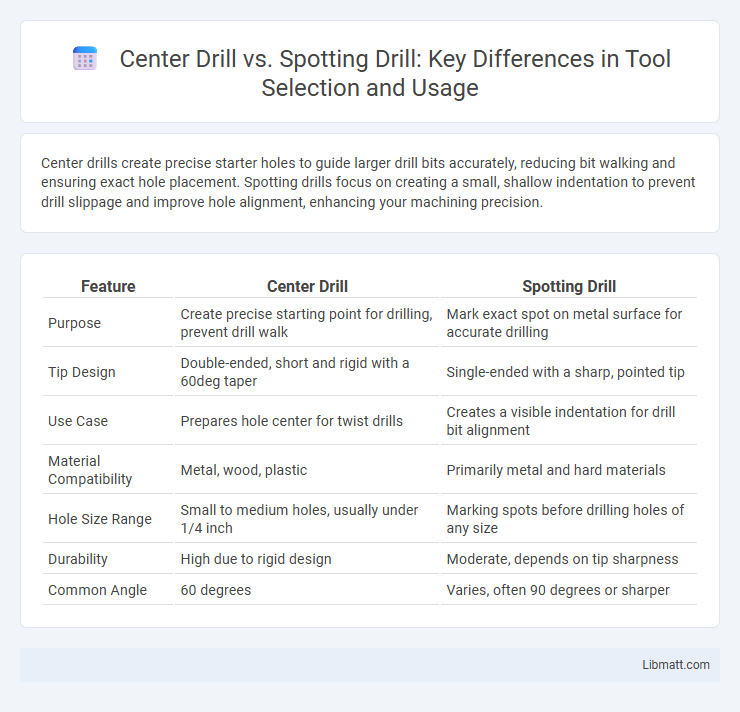

Center drills create precise starter holes to guide larger drill bits accurately, reducing bit walking and ensuring exact hole placement. Spotting drills focus on creating a small, shallow indentation to prevent drill slippage and improve hole alignment, enhancing your machining precision.

Table of Comparison

| Feature | Center Drill | Spotting Drill |

|---|---|---|

| Purpose | Create precise starting point for drilling, prevent drill walk | Mark exact spot on metal surface for accurate drilling |

| Tip Design | Double-ended, short and rigid with a 60deg taper | Single-ended with a sharp, pointed tip |

| Use Case | Prepares hole center for twist drills | Creates a visible indentation for drill bit alignment |

| Material Compatibility | Metal, wood, plastic | Primarily metal and hard materials |

| Hole Size Range | Small to medium holes, usually under 1/4 inch | Marking spots before drilling holes of any size |

| Durability | High due to rigid design | Moderate, depends on tip sharpness |

| Common Angle | 60 degrees | Varies, often 90 degrees or sharper |

Introduction to Center Drill vs Spotting Drill

Center drills provide a precise starting point for subsequent drilling operations, ensuring accuracy and preventing drill bit wandering. Spotting drills, often shorter and sturdier, create a small, shallow hole to guide larger drills and improve centering on tough materials. Both tools enhance drilling precision but serve slightly different preparatory purposes in machining processes.

Definitions: What Is a Center Drill?

A center drill is a short, rigid drill used to create a precise starting point or pilot hole for a larger drill bit, ensuring accurate hole placement and preventing bit walking. It features a thick body with a small, angled tip designed to produce a conical hole for lathe centers. Spotting drills, by contrast, primarily create shallow, flat-bottomed indentations to guide subsequent drilling operations but lack the rigid design of center drills.

Definitions: What Is a Spotting Drill?

A spotting drill is a specialized cutting tool designed to create a precise starting point or small pilot hole on a workpiece, ensuring accurate placement for subsequent drilling operations. Unlike center drills, which combine a tapered tip and pilot drill to establish both a center hole and start hole, spotting drills focus solely on producing a flat-bottomed indentation. This indentation prevents larger drill bits from wandering, improving accuracy and reducing tool wear during the main drilling process.

Key Differences Between Center Drill and Spotting Drill

Center drills are primarily designed to create a small, precise starting hole that guides the main drill bit and prevents it from wandering, featuring a thicker and more robust tip. Spotting drills, on the other hand, focus on creating a precise conical indentation that ensures accurate hole placement for drilling or countersinking, often with a sharper tip angle. The key difference lies in their specific applications: center drills prepare pilot holes for drilling operations, while spotting drills mark exact positions on the workpiece to enhance drilling accuracy.

Applications of Center Drills

Center drills are primarily used to create a precise starting point for larger drill bits, ensuring accurate hole placement and preventing bit wandering in metalworking and machining applications. They are essential for preparing workpieces for subsequent deeper drilling operations, especially in engineering and manufacturing environments where precision is critical. You can rely on center drills to improve the quality of drilled holes by providing stable pilot points that enhance overall machining accuracy.

Applications of Spotting Drills

Spotting drills are primarily used to create precise starter holes for larger drill bits, ensuring accuracy and preventing bit wandering during the drilling process. They are essential in metalworking and manufacturing to maintain hole alignment and improve surface finish quality on workpieces. These drills are commonly applied in machining tasks involving countersinking, chamfering, and preparing holes for threading or tapping operations.

Advantages and Disadvantages of Center Drills

Center drills ensure precise hole location by creating a pilot hole that guides subsequent drilling, reducing the risk of drill bit wandering. Their short, rigid design enhances stability and durability, making them ideal for accurate center punching and starting holes on metal surfaces. However, center drills may wear out faster under heavy-duty applications and are less effective for deep hole drilling compared to spotting drills, which can handle both marking and initial hole shaping with less breakage.

Advantages and Disadvantages of Spotting Drills

Spotting drills offer precise location marking and reduce wandering during drilling, enhancing accuracy for subsequent operations like reaming or tapping. Their design allows for deeper entry points without excessive material removal, minimizing workpiece damage and tool breakage, yet they may be less effective on very hard materials where center drills perform better. Spotting drills require careful alignment and setup, as improper use can lead to inaccurate holes or increased wear on the drill bit.

Selecting the Right Drill for Your Project

Selecting the right drill requires understanding the specific applications of center drills and spotting drills. Center drills create a precise starting point for larger drill bits, preventing bit wander and ensuring accuracy, ideal for metalworking and precise hole placement. Spotting drills enlarge and chamfer pilot holes to improve reaming and tapping accuracy, making them essential when finishing holes or preparing surfaces for threading.

Summary: Center Drill vs Spotting Drill – Which to Choose?

Center drills create a precise starting point for larger drill bits by producing a small, conical hole that prevents bit wander, while spotting drills focus on enlarging existing pilot holes to improve alignment and reduce drill breakage. Choosing between a center drill and spotting drill depends on whether you need to establish an initial guide hole or refine an existing one for accuracy and tool longevity. Your decision should consider the material thickness, hole size, and drilling precision required for optimal machining results.

Center drill vs spotting drill Infographic

libmatt.com

libmatt.com