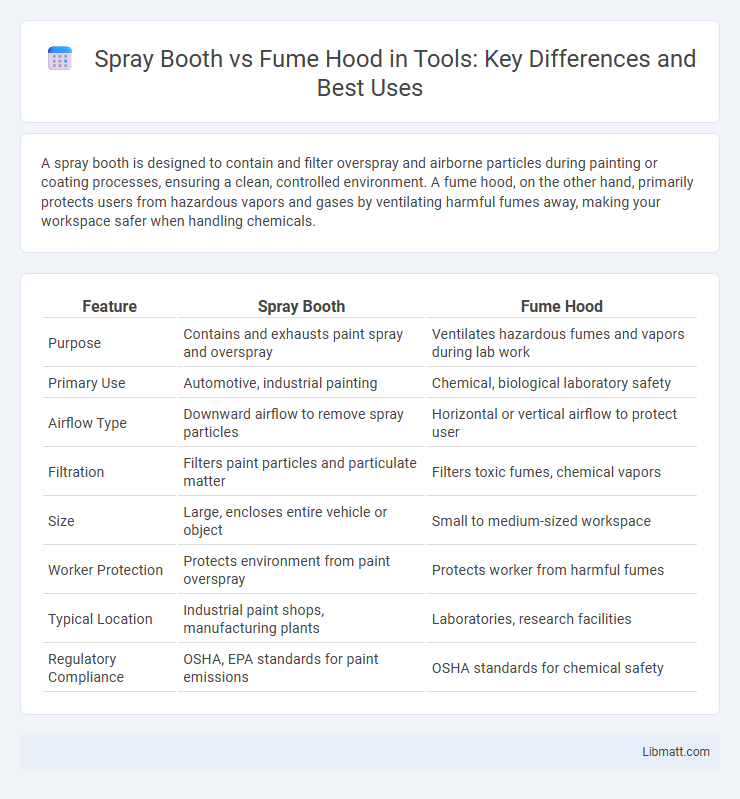

A spray booth is designed to contain and filter overspray and airborne particles during painting or coating processes, ensuring a clean, controlled environment. A fume hood, on the other hand, primarily protects users from hazardous vapors and gases by ventilating harmful fumes away, making your workspace safer when handling chemicals.

Table of Comparison

| Feature | Spray Booth | Fume Hood |

|---|---|---|

| Purpose | Contains and exhausts paint spray and overspray | Ventilates hazardous fumes and vapors during lab work |

| Primary Use | Automotive, industrial painting | Chemical, biological laboratory safety |

| Airflow Type | Downward airflow to remove spray particles | Horizontal or vertical airflow to protect user |

| Filtration | Filters paint particles and particulate matter | Filters toxic fumes, chemical vapors |

| Size | Large, encloses entire vehicle or object | Small to medium-sized workspace |

| Worker Protection | Protects environment from paint overspray | Protects worker from harmful fumes |

| Typical Location | Industrial paint shops, manufacturing plants | Laboratories, research facilities |

| Regulatory Compliance | OSHA, EPA standards for paint emissions | OSHA standards for chemical safety |

Introduction: Understanding Spray Booths and Fume Hoods

Spray booths and fume hoods serve distinct purposes in controlling airborne contaminants; spray booths primarily contain and filter overspray in painting and coating applications to protect both the environment and workers. Fume hoods focus on ventilating hazardous fumes, vapors, and dust in laboratory or industrial settings to ensure user safety by continuously exhausting contaminated air. Understanding these differences helps you select the right equipment for your specific safety and environmental needs.

Core Functions: What Each System Does

Spray booths provide a controlled environment for applying paint or coatings, capturing overspray to ensure a clean finish and protect workers from inhaling harmful particles. Fume hoods primarily focus on ventilating and containing hazardous chemical vapors, gases, and fumes to maintain user safety during laboratory or industrial processes. Both systems optimize air quality but serve distinctly different purposes based on the type of airborne contaminants they manage.

Key Differences Between Spray Booths and Fume Hoods

Spray booths and fume hoods both control airborne contaminants but serve different industrial needs; spray booths are designed to contain and ventilate overspray and paint fumes in painting applications, while fume hoods primarily protect users by capturing and exhausting hazardous chemical vapors during laboratory work. Spray booths feature large enclosed spaces with high-efficiency filtration tailored for particulates, whereas fume hoods offer localized ventilation with adjustable airflow to isolate chemical emissions. Understanding these key differences helps ensure Your facility chooses the right equipment for effective contaminant control and worker safety.

Applications: When to Use a Spray Booth vs. a Fume Hood

Spray booths are ideal for applications involving paint, coatings, or aerosolized substances requiring controlled airflow to capture overspray and ensure even drying, commonly used in automotive and industrial finishing processes. Fume hoods are designed for chemical experiments and processes that generate hazardous vapors, gases, or fumes, providing containment and ventilation to protect users in laboratories and chemical manufacturing. Selecting between a spray booth and a fume hood depends on operational needs: spray booths suit large-scale spraying and finishing tasks, while fume hoods are essential for handling toxic or volatile chemical substances safely.

Ventilation Mechanisms Compared

Spray booths utilize high-velocity airflow to capture and exhaust overspray particles and volatile organic compounds, maintaining a clean and safe environment for painting applications. Fume hoods rely on face-velocity airflow to contain and ventilate hazardous fumes and vapors directly away from the user's breathing zone. The key ventilation difference lies in spray booths' emphasis on directional airflow for particulate control versus fume hoods' focus on containment and removal of toxic gases.

Safety Features and Compliance

Spray booths are equipped with explosion-proof lighting, fire suppression systems, and high-efficiency air filtration to ensure compliance with OSHA and NFPA standards for flammable vapors and particulates. Fume hoods include adjustable airflow controls, sash alarms, and HEPA filters designed to capture hazardous chemical fumes, meeting ANSI/ASHRAE ventilation guidelines. Both systems incorporate safety interlocks and monitoring devices to maintain proper containment and protect operators from toxic exposure.

Installation and Maintenance Requirements

Spray booths require specialized ventilation systems and regular filter replacements to manage overspray and ensure air quality, while fume hoods demand precise airflow calibration and frequent sash inspections for effective containment of hazardous vapors. Installation of spray booths often involves significant spatial considerations and compliance with fire safety codes, whereas fume hoods need integration with building exhaust systems and routine certification to maintain OSHA standards. Your choice depends on maintenance capabilities and the complexity of installation suited to your operational environment.

Cost Considerations and Budgeting

Spray booths typically require higher initial investment due to specialized ventilation systems and fire safety features, whereas fume hoods generally have lower upfront costs but demand consistent maintenance to ensure proper airflow and filtration. Budgeting for spray booths must include expenses for installation, compliance with regulatory standards, and periodic replacement of filters, while fume hood costs often focus on energy consumption and routine inspections. Long-term operational expenses tend to be higher for spray booths because of ventilation requirements and material handling, making cost considerations critical when choosing between the two.

Environmental Impact and Filtration Efficiency

Spray booths typically provide higher filtration efficiency for removing paint overspray and volatile organic compounds (VOCs), minimizing environmental impact by capturing hazardous particles before release. Fume hoods focus on containing and exhausting harmful chemical fumes, but may allow finer pollutants to escape if filtration systems are not optimized. Choosing the right equipment for your workspace affects both environmental safety and air quality control.

Choosing the Right Option for Your Facility

Selecting between a spray booth and a fume hood depends on the specific industrial application and safety requirements of your facility. Spray booths are designed for controlling overspray and ensuring proper ventilation during painting or coating processes, while fume hoods provide localized containment of hazardous fumes and vapors in laboratory or chemical handling environments. Assessing factors such as airflow capacity, filtration efficiency, size constraints, and regulatory compliance will guide the optimal choice to protect worker health and meet operational needs.

Spray booth vs fume hood Infographic

libmatt.com

libmatt.com