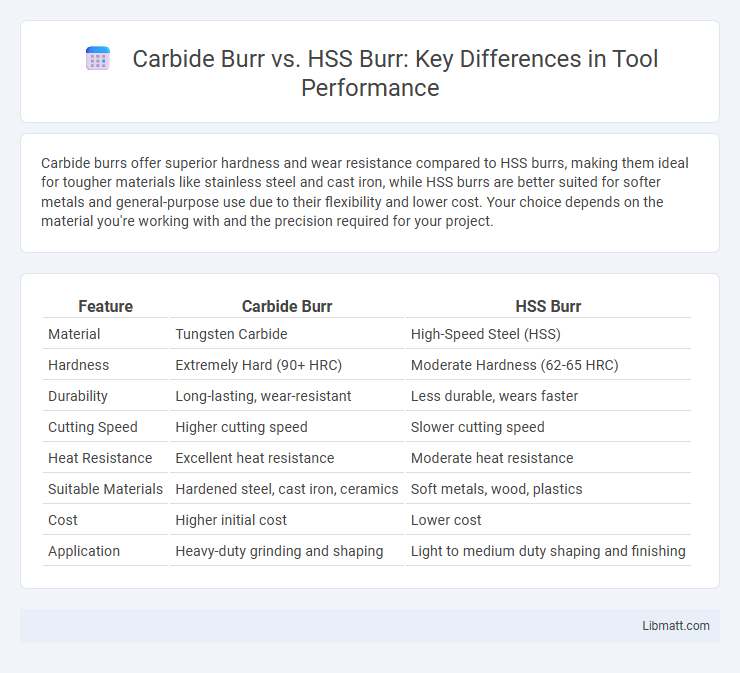

Carbide burrs offer superior hardness and wear resistance compared to HSS burrs, making them ideal for tougher materials like stainless steel and cast iron, while HSS burrs are better suited for softer metals and general-purpose use due to their flexibility and lower cost. Your choice depends on the material you're working with and the precision required for your project.

Table of Comparison

| Feature | Carbide Burr | HSS Burr |

|---|---|---|

| Material | Tungsten Carbide | High-Speed Steel (HSS) |

| Hardness | Extremely Hard (90+ HRC) | Moderate Hardness (62-65 HRC) |

| Durability | Long-lasting, wear-resistant | Less durable, wears faster |

| Cutting Speed | Higher cutting speed | Slower cutting speed |

| Heat Resistance | Excellent heat resistance | Moderate heat resistance |

| Suitable Materials | Hardened steel, cast iron, ceramics | Soft metals, wood, plastics |

| Cost | Higher initial cost | Lower cost |

| Application | Heavy-duty grinding and shaping | Light to medium duty shaping and finishing |

Introduction to Carbide Burrs and HSS Burrs

Carbide burrs feature tungsten carbide cutting heads renowned for superior hardness, heat resistance, and extended lifespan, making them ideal for machining tough metals and abrasive materials. HSS (High-Speed Steel) burrs, crafted from high-speed steel, offer excellent toughness and sharpness suited for general-purpose cutting, shaping, and deburring of softer materials like aluminum and mild steel. Both types deliver precision in rotary tools, but carbide burrs outperform HSS burrs in heavy-duty applications due to their enhanced durability and cutting efficiency.

Material Composition: Carbide vs HSS

Carbide burrs are composed of tungsten carbide, a compound known for its exceptional hardness and resistance to wear, making them ideal for heavy-duty applications and cutting hard materials. In contrast, High-Speed Steel (HSS) burrs are made from a steel alloy containing elements like tungsten and molybdenum, offering superior toughness and flexibility but lower hardness compared to carbide. The material composition of carbide burrs delivers longer tool life and higher cutting speeds, while HSS burrs provide better shock resistance and are easier to sharpen.

Manufacturing Process Differences

Carbide burrs are manufactured through a process called powder metallurgy, where tungsten carbide powder is pressed and sintered at high temperatures, resulting in a dense and extremely hard tool. HSS burrs are made by forging or machining high-speed steel, followed by heat treatment to enhance toughness and wear resistance. Your choice between carbide and HSS burrs depends on the specific manufacturing process benefits, with carbide offering superior hardness and HSS providing greater flexibility under impact.

Cutting Performance and Efficiency

Carbide burrs deliver superior cutting performance and efficiency due to their hardness and heat resistance, making them ideal for high-speed applications and materials like stainless steel or hardened metals. HSS burrs, while offering good sharpness and durability, tend to wear faster and generate more heat, reducing efficiency during prolonged use. Choosing carbide burrs enhances your productivity by providing faster material removal and longer tool life.

Durability and Lifespan Comparison

Carbide burrs offer significantly greater durability and a longer lifespan compared to HSS burrs due to their hardness and resistance to heat and wear. HSS burrs tend to dull faster when used on harder materials, requiring more frequent replacements. Choosing a carbide burr for your projects ensures extended tool life and consistent performance, especially in demanding applications.

Applications and Suitable Materials

Carbide burrs excel in machining hard materials such as stainless steel, cast iron, and hardened metals due to their superior hardness and heat resistance. HSS burrs are ideal for softer metals like aluminum, brass, and mild steel, offering clean cuts and extended tool life in less demanding applications. Choosing the right burr depends on your material's hardness and the precision required for your project.

Cost Analysis: Carbide Burr vs HSS Burr

Carbide burrs generally have a higher upfront cost compared to HSS burrs due to their superior hardness and longer lifespan. However, carbide burrs offer better wear resistance and maintain cutting efficiency over extended use, potentially reducing replacement frequency and overall expenses. In contrast, HSS burrs are more affordable initially but may require more frequent replacement, leading to higher long-term costs in high-volume or heavy-duty applications.

Sharpening and Maintenance Needs

Carbide burrs require less frequent sharpening due to their hardness and wear resistance, making them ideal for heavy-duty applications and extended use. HSS burrs, while easier to sharpen at home or in a workshop, need more regular maintenance to maintain cutting efficiency, especially when working with softer metals. Your choice depends on balancing the convenience of carbide's low upkeep against the straightforward sharpening process of HSS burrs.

Safety Considerations and Operator Tips

Carbide burrs offer enhanced durability and higher cutting speeds compared to HSS burrs, but operators must wear proper protective gear due to increased heat generation and potential for chip ejection. HSS burrs, being softer, pose less risk of tool breakage but require slower speeds to avoid overheating, ensuring safer handling. Maintaining steady pressure and avoiding excessive force prolong tool life and reduce risks associated with vibration and kickback for both types.

Choosing the Right Burr for Your Project

Carbide burrs offer superior heat resistance and durability, making them ideal for cutting hard materials like stainless steel and cast iron. HSS burrs provide a cost-effective option for softer metals and general-purpose deburring tasks, with faster cutting speeds but less longevity. Choosing the right burr depends on your project's material hardness and precision requirements, ensuring optimal performance and tool life.

Carbide burr vs HSS burr Infographic

libmatt.com

libmatt.com