A hardness tester measures a material's resistance to indentation or scratching, providing quick insight into surface strength, while a tensile tester evaluates the material's behavior under pulling forces to determine properties like tensile strength, elongation, and elasticity. Your choice depends on whether surface hardness or overall tensile performance is more critical for your application.

Table of Comparison

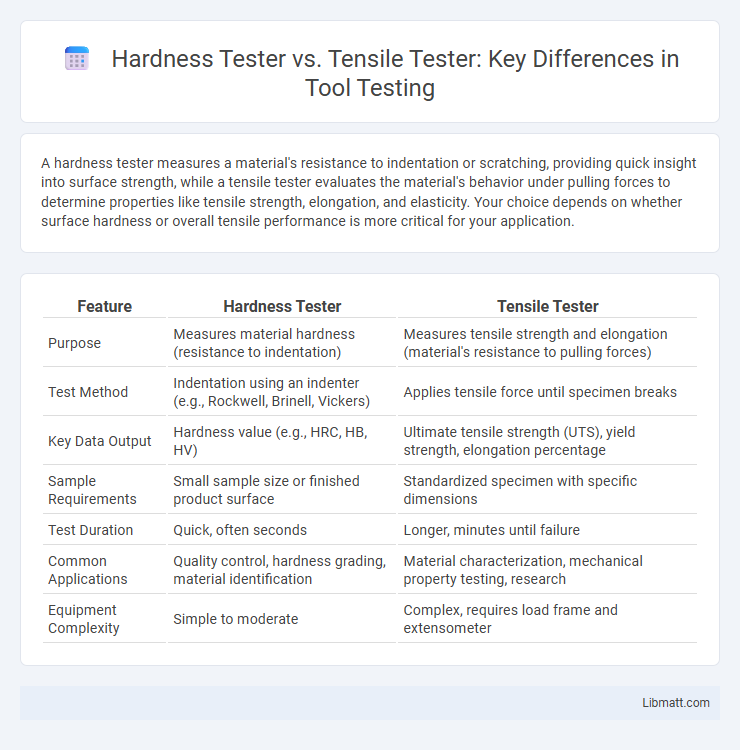

| Feature | Hardness Tester | Tensile Tester |

|---|---|---|

| Purpose | Measures material hardness (resistance to indentation) | Measures tensile strength and elongation (material's resistance to pulling forces) |

| Test Method | Indentation using an indenter (e.g., Rockwell, Brinell, Vickers) | Applies tensile force until specimen breaks |

| Key Data Output | Hardness value (e.g., HRC, HB, HV) | Ultimate tensile strength (UTS), yield strength, elongation percentage |

| Sample Requirements | Small sample size or finished product surface | Standardized specimen with specific dimensions |

| Test Duration | Quick, often seconds | Longer, minutes until failure |

| Common Applications | Quality control, hardness grading, material identification | Material characterization, mechanical property testing, research |

| Equipment Complexity | Simple to moderate | Complex, requires load frame and extensometer |

Introduction to Material Testing

Material testing evaluates properties such as hardness and tensile strength to determine material performance under stress. Hardness testers measure resistance to indentation or scratching, while tensile testers assess resistance to pulling forces by determining tensile strength, yield strength, and elongation. Choosing the right test depends on your material's application and required mechanical properties.

Hardness Tester: Overview and Principles

Hardness testers measure a material's resistance to deformation, typically using methods like Rockwell, Brinell, and Vickers to assess surface hardness. These devices operate by applying a specific force through an indenter and evaluating the indentation size or depth to quantify hardness levels. Hardness testing is crucial for predicting material durability, wear resistance, and suitability for various industrial applications.

Tensile Tester: Overview and Principles

A tensile tester measures a material's mechanical properties by applying controlled tension until failure, determining tensile strength, elongation, and Young's modulus. It operates based on precise load application and elongation measurement to assess ductility and structural performance. Tensile testing is crucial for evaluating metals, polymers, and composites in engineering and quality control.

Key Differences Between Hardness and Tensile Testing

Hardness testers measure a material's resistance to indentation or surface deformation, providing quick and localized hardness values such as Brinell, Rockwell, or Vickers scales. Tensile testers evaluate a material's response to uniaxial tensile force, determining mechanical properties like ultimate tensile strength, yield strength, and elongation before failure. Your choice between hardness and tensile testing depends on whether surface resistance or overall mechanical performance under tension is more critical for your application.

Applications of Hardness Testers

Hardness testers are primarily used to measure a material's resistance to deformation and wear, making them essential for quality control in manufacturing processes involving metals, plastics, and ceramics. These testers help ensure that components like gears, bearings, and molds meet durability standards, preventing premature failure in industrial applications. Your choice of a hardness tester is ideal for rapid, non-destructive testing when assessing surface properties and hardness gradients across different materials.

Applications of Tensile Testers

Tensile testers are primarily used in material science and manufacturing to evaluate the mechanical properties of metals, plastics, and composites by measuring tensile strength, elongation, and yield strength. These testers are essential in quality control for automotive, aerospace, construction, and biomedical industries to ensure materials meet performance standards. They facilitate research and development by providing critical data for material selection, structural analysis, and failure prediction under tensile loads.

Pros and Cons: Hardness Tester vs Tensile Tester

Hardness testers offer quick, non-destructive testing with minimal sample preparation, ideal for measuring surface resistance to indentation but may not fully represent material strength under load. Tensile testers provide comprehensive data on material strength, ductility, and elongation by applying controlled tension, though they require specimen destruction and longer testing times. Your choice depends on whether you prioritize rapid surface hardness assessment or detailed mechanical property analysis.

Accuracy and Reliability Comparison

Hardness testers provide precise surface hardness measurements critical for assessing material wear resistance, while tensile testers offer accurate evaluation of a material's ultimate strength and elongation under load. Tensile testers generally deliver higher reliability in determining mechanical properties due to their ability to measure behavior under actual stress conditions, whereas hardness testers may show variability depending on surface preparation and indentation method. For comprehensive material characterization, tensile testers are often preferred when exact mechanical performance data is required, whereas hardness testers serve well for quick, non-destructive quality control.

Choosing the Right Tester for Your Needs

Selecting the appropriate hardness tester or tensile tester depends on the specific material properties and testing objectives, such as surface resistance or overall mechanical strength. Hardness testers like Rockwell, Brinell, or Vickers are ideal for quick surface hardness measurements, while tensile testers provide detailed stress-strain data crucial for structural analysis. Considering factors like material type, precision requirements, and application standards ensures accurate and relevant testing results.

Conclusion: Which Tester Suits Your Application?

Hardness testers measure material resistance to indentation, ideal for quickly assessing surface strength and wear resistance, while tensile testers evaluate a material's behavior under tension, providing detailed insights into its elongation, yield strength, and ultimate tensile strength. Your choice depends on the specific property critical to your application--opt for a hardness tester for rapid assessments of surface durability or a tensile tester when understanding material deformation and breaking points is essential. Selecting the right tester ensures accurate data for quality control and material selection tailored to your product's performance requirements.

Hardness tester vs tensile tester Infographic

libmatt.com

libmatt.com