A fixed vise provides a stable and immovable clamping solution, ideal for precision tasks that require consistent positioning. Your choice depends on whether you need quick angle adjustments, which a swivel vise offers, allowing you to rotate and lock the workpiece at various angles for versatility.

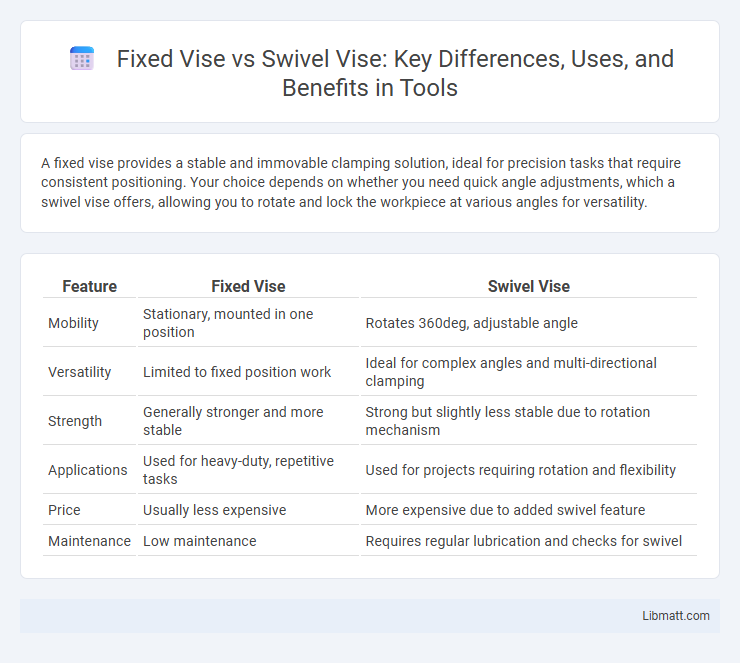

Table of Comparison

| Feature | Fixed Vise | Swivel Vise |

|---|---|---|

| Mobility | Stationary, mounted in one position | Rotates 360deg, adjustable angle |

| Versatility | Limited to fixed position work | Ideal for complex angles and multi-directional clamping |

| Strength | Generally stronger and more stable | Strong but slightly less stable due to rotation mechanism |

| Applications | Used for heavy-duty, repetitive tasks | Used for projects requiring rotation and flexibility |

| Price | Usually less expensive | More expensive due to added swivel feature |

| Maintenance | Low maintenance | Requires regular lubrication and checks for swivel |

Introduction to Fixed and Swivel Vises

Fixed vises provide a stable, immovable clamping platform ideal for precision tasks requiring consistent positioning. Swivel vises feature a rotating base that allows the user to adjust the angle of the workpiece for enhanced flexibility during complex projects. Both types of vises are essential tools in woodworking, metalworking, and assembly applications, each optimized for different operational needs.

What is a Fixed Vise?

A fixed vise is a woodworking or metalworking clamping tool securely mounted to a workbench, providing stable, immovable support for holding materials during cutting, drilling, or shaping tasks. Its rigid design ensures precise alignment and maximum stability, making it ideal for repetitive, heavy-duty work. Unlike swivel vises, fixed vises do not rotate, prioritizing firmness and accuracy over versatility.

What is a Swivel Vise?

A swivel vise features a rotating base that allows the user to adjust the angle of the workpiece for precise positioning during tasks. Unlike a fixed vise, which remains stationary and offers limited movement, a swivel vise enhances versatility in woodworking, metalworking, and other crafts by enabling multi-angle access. This adjustability improves efficiency and accuracy when clamping irregularly shaped objects or working in tight spaces.

Key Differences Between Fixed and Swivel Vises

Fixed vises offer a stable, rigid clamping solution ideal for precise, heavy-duty tasks where stability is critical, while swivel vises provide versatility with a rotating base allowing for adjustable positioning and easier access to workpieces at various angles. The key differences lie in mobility and application; fixed vises excel in strength and firmness, whereas swivel vises enhance flexibility and convenience during complex projects. Choosing the right vise depends on your specific workshop needs, balancing the requirement for fixed stability against the benefit of dynamic adjustability.

Pros and Cons of Fixed Vises

Fixed vises offer superior stability and strength, making them ideal for heavy-duty tasks that require rigorous clamping force without movement. Their solid construction ensures consistent alignment, which enhances precision in woodworking and metalworking projects. However, the lack of rotational capability limits versatility, as fixed vises cannot be adjusted to different angles, reducing convenience in complex or multi-angle operations.

Pros and Cons of Swivel Vises

Swivel vises offer enhanced flexibility by allowing the jaws to rotate, enabling users to work on angled or irregularly shaped objects with ease, a key advantage over fixed vises which remain stationary. However, swivel vises may sacrifice some stability and clamping strength compared to fixed vises, making them less ideal for tasks requiring maximum holding power. The trade-off between versatility and rigidity positions swivel vises as the preferred choice for complex projects, while fixed vises excel in heavy-duty, stable clamping applications.

Best Applications for Fixed Vises

Fixed vises provide maximum stability and clamping strength, making them ideal for heavy-duty tasks such as metalworking, woodworking, and machining where precision and rigidity are crucial. Their solid base and immovable design prevent any movement during operation, ensuring reliable and consistent hold on workpieces. These vises are best suited for applications requiring high torque and repetitive use, such as drill presses and bench work.

Best Applications for Swivel Vises

Swivel vises excel in applications requiring versatile positioning, such as intricate metalworking, woodworking, and assembly tasks where adjustable angles enhance precision. Their adjustable rotation allows craftsmen to securely clamp workpieces at various angles without repositioning the base, making them ideal for projects with complex geometries or multi-sided components. This flexibility supports enhanced ergonomic workflow and reduces setup time in repetitive or detailed machining, soldering, and crafting operations.

How to Choose the Right Vise for Your Workshop

Choosing the right vise for your workshop depends on the specific tasks and flexibility you require. A fixed vise offers strong, stable clamping ideal for heavy-duty or repetitive work, while a swivel vise provides adjustable angles for versatile positioning and improved access to workpieces. Assess your typical projects and workspace layout to determine whether stability or maneuverability aligns best with your needs.

Final Verdict: Fixed Vise vs Swivel Vise

Fixed vises provide superior stability and strength, making them ideal for heavy-duty tasks requiring a secure grip. Swivel vises offer versatility and ease of positioning with adjustable angles, which enhances accessibility for complex or multi-angle projects. The final verdict depends on the specific needs of the task: choose a fixed vise for maximum rigidity and a swivel vise for flexibility and convenience.

Fixed vise vs swivel vise Infographic

libmatt.com

libmatt.com