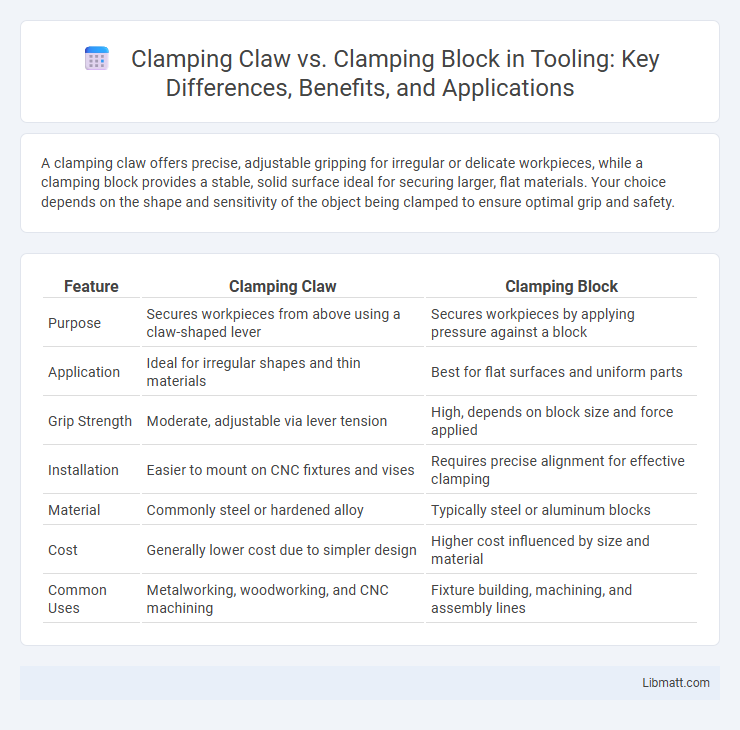

A clamping claw offers precise, adjustable gripping for irregular or delicate workpieces, while a clamping block provides a stable, solid surface ideal for securing larger, flat materials. Your choice depends on the shape and sensitivity of the object being clamped to ensure optimal grip and safety.

Table of Comparison

| Feature | Clamping Claw | Clamping Block |

|---|---|---|

| Purpose | Secures workpieces from above using a claw-shaped lever | Secures workpieces by applying pressure against a block |

| Application | Ideal for irregular shapes and thin materials | Best for flat surfaces and uniform parts |

| Grip Strength | Moderate, adjustable via lever tension | High, depends on block size and force applied |

| Installation | Easier to mount on CNC fixtures and vises | Requires precise alignment for effective clamping |

| Material | Commonly steel or hardened alloy | Typically steel or aluminum blocks |

| Cost | Generally lower cost due to simpler design | Higher cost influenced by size and material |

| Common Uses | Metalworking, woodworking, and CNC machining | Fixture building, machining, and assembly lines |

Introduction to Clamping Systems

Clamping systems are essential for securely holding workpieces during machining or assembly processes, with clamping claws and clamping blocks being two popular options. Clamping claws provide flexible gripping by applying pressure from multiple points, ideal for irregular shapes or quick adjustments. Clamping blocks offer robust, stable support through solid contact surfaces, making them suitable for precise, heavy-duty applications to ensure your workpiece remains immobile.

What is a Clamping Claw?

A clamping claw is a mechanical device designed to grip and hold workpieces securely during machining or assembly processes, ensuring precision and stability. Unlike a clamping block, which provides a flat surface for pressure distribution, the clamping claw uses a curved or hooked shape to exert targeted force, preventing slippage. Understanding the function of your clamping claw helps optimize tool setup and improves the accuracy of your manufacturing operations.

What is a Clamping Block?

A clamping block is a precision-machined component designed to secure workpieces firmly during machining or assembly processes by providing a stable and adjustable gripping surface. Unlike clamping claws, which use hook-like extensions to grip objects, clamping blocks distribute clamping force evenly across the contact area, reducing the risk of damage and improving stability. Clamping blocks are essential in fixtures and jigs for ensuring accurate alignment and repeatability in manufacturing operations.

Key Differences Between Clamping Claws and Clamping Blocks

Clamping claws provide precise, adjustable grip with multiple contact points ideal for securing irregular shapes, whereas clamping blocks offer stable, broad support for uniform pressure distribution on flat surfaces. Clamping claws typically allow quicker repositioning and fine-tuned clamping force, while clamping blocks excel in applications requiring consistent, heavy-duty stability. Material composition and design versatility also differ, with claws often made from hardened steel for durability and blocks from solid or composite materials to withstand heavy loads.

Applications of Clamping Claws

Clamping claws are widely used in machining and assembly processes where precision and secure holding of irregular or delicate workpieces are required. Their design allows for firm grip without damaging the surface, making them ideal for applications in metalworking, woodworking, and electronics manufacturing. Your choice of clamping claws enhances stability and repeatability in setups involving complex geometries or sensitive materials.

Applications of Clamping Blocks

Clamping blocks are essential in woodworking and metalworking for securely holding irregularly shaped or small workpieces during machining, ensuring precision and stability. Unlike clamping claws, clamping blocks distribute pressure evenly, minimizing deformation and surface damage, making them ideal for delicate or detailed applications. Your projects benefit from increased accuracy and repeatability when using clamping blocks in setups like milling, drilling, and grinding.

Advantages of Clamping Claws

Clamping claws offer precise and secure grip on irregularly shaped or delicate workpieces, reducing the risk of surface damage compared to clamping blocks. Their design allows faster setup and adjustment, enhancing operational efficiency in dynamic machining environments. Clamping claws also provide greater versatility by accommodating various shapes and sizes without the need for custom fixtures.

Advantages of Clamping Blocks

Clamping blocks offer enhanced stability and even pressure distribution, reducing the risk of workpiece damage during machining processes. Their versatile design allows for quick setup adjustments, improving workflow efficiency and precision in your projects. Compared to clamping claws, clamping blocks provide superior support for irregularly shaped or delicate materials, ensuring consistent and secure holds.

Factors to Consider When Choosing Between Clamping Claw and Clamping Block

When choosing between clamping claw and clamping block, consider the workpiece material, shape, and machining forces involved to ensure optimal grip and stability. Clamping claws offer quick, flexible positioning ideal for irregular shapes, while clamping blocks provide robust, uniform pressure suitable for heavy-duty applications. Machine compatibility and setup time also influence the selection, with clamping blocks favored for repetitive precision tasks and clamping claws for versatile, fast adjustments.

Conclusion: Selecting the Right Clamping Solution

Choosing between a clamping claw and a clamping block depends on the specific application requirements such as workpiece size, shape, and machining force. Clamping claws provide quick, flexible positioning ideal for irregular or small parts, while clamping blocks offer higher stability and precision for heavy-duty or repeatable operations. Evaluating the machining environment and desired clamping force ensures optimal selection, improving efficiency and safety in manufacturing processes.

Clamping claw vs clamping block Infographic

libmatt.com

libmatt.com