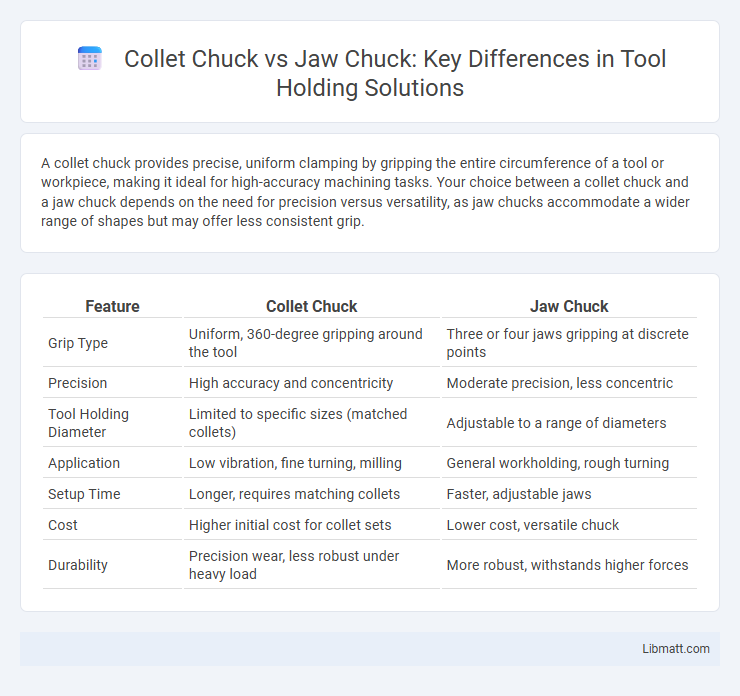

A collet chuck provides precise, uniform clamping by gripping the entire circumference of a tool or workpiece, making it ideal for high-accuracy machining tasks. Your choice between a collet chuck and a jaw chuck depends on the need for precision versus versatility, as jaw chucks accommodate a wider range of shapes but may offer less consistent grip.

Table of Comparison

| Feature | Collet Chuck | Jaw Chuck |

|---|---|---|

| Grip Type | Uniform, 360-degree gripping around the tool | Three or four jaws gripping at discrete points |

| Precision | High accuracy and concentricity | Moderate precision, less concentric |

| Tool Holding Diameter | Limited to specific sizes (matched collets) | Adjustable to a range of diameters |

| Application | Low vibration, fine turning, milling | General workholding, rough turning |

| Setup Time | Longer, requires matching collets | Faster, adjustable jaws |

| Cost | Higher initial cost for collet sets | Lower cost, versatile chuck |

| Durability | Precision wear, less robust under heavy load | More robust, withstands higher forces |

Introduction to Collet Chucks and Jaw Chucks

Collet chucks provide uniform gripping force through a cylindrical sleeve that tightly clamps around a workpiece, ensuring high precision and minimal runout for machining tasks. Jaw chucks feature adjustable jaws, typically three or four, that grip irregularly shaped or larger workpieces with variable clamping force, offering versatility for diverse applications. Both chuck types play essential roles in CNC machines, lathes, and milling equipment, optimized according to workpiece geometry and machining accuracy requirements.

Fundamental Differences Between Collet and Jaw Chucks

Collet chucks provide precise gripping by evenly distributing clamping force around the entire circumference of the tool or workpiece, making them ideal for high-accuracy applications. Jaw chucks use adjustable jaws that grip the workpiece at specific points, offering versatility for various shapes and sizes but often with less uniform pressure. Understanding these fundamental differences helps you select the optimal chuck type for your machining needs, balancing precision and adaptability.

Advantages of Collet Chucks

Collet chucks provide superior concentricity and gripping force, ensuring precise workpiece alignment and reducing runout, which is essential for high-accuracy machining. Their design allows for uniform clamping pressure around the entire circumference of the workpiece, minimizing deformation and slippage during high-speed operations. Collet chucks also offer faster setup times and easier adjustment compared to jaw chucks, enhancing overall productivity in manufacturing processes.

Benefits of Using Jaw Chucks

Jaw chucks provide superior grip strength and versatility, accommodating a wide range of workpiece shapes and sizes, which enhances machining precision and stability. Their adjustable jaws ensure quick and secure clamping, reducing setup time and improving overall productivity in milling, drilling, and lathe operations. Jaw chucks excel in heavy-duty applications where consistent holding force and durability are critical for optimal performance.

Applications Best Suited for Collet Chucks

Collet chucks are best suited for high-precision machining applications requiring consistent concentricity and minimal runout, such as CNC milling and drilling of small-diameter workpieces. They excel in gripping round, hexagonal, or square tools and workpieces with uniform diameters, making them ideal for lathe turning, reaming, and tapping operations. Compared to jaw chucks, collet chucks provide superior clamping force and accuracy for delicate or intricate components in aerospace, automotive, and medical device manufacturing.

Ideal Uses for Jaw Chucks

Jaw chucks are ideal for applications requiring rapid and versatile workpiece changes, such as in metalworking and woodworking lathes. They securely grip irregularly shaped objects or larger diameters with adjustable jaws that accommodate varying sizes. Their robust design suits heavy-duty machining tasks where strong clamping force and easy setup are essential.

Precision and Gripping Power Comparison

Collet chucks provide superior precision by offering uniform gripping force around the entire circumference of the tool or workpiece, minimizing runout and vibration for high-accuracy machining. Jaw chucks deliver greater gripping power and versatility with adjustable jaws that can clamp irregularly shaped objects, but they may introduce slight misalignment under heavy load. Selecting between collet and jaw chucks depends on whether your priority is maximum precision or enhanced gripping strength for diverse applications.

Maintenance and Setup Considerations

Collet chucks require precise alignment and regular cleaning to maintain grip accuracy, minimizing the risk of workpiece slippage during machining. Jaw chucks offer easier setup with adjustable jaws, but demand periodic inspection and lubrication of moving parts to ensure consistent clamping force. Understanding these maintenance and setup differences helps you optimize tool performance and reduce downtime in your machining operations.

Cost and Operational Efficiency Analysis

Collet chucks typically offer higher precision and better grip for small-diameter workpieces, resulting in improved operational efficiency and reduced machining errors, but often come with a higher initial cost due to their specialized design and manufacturing complexity. Jaw chucks, on the other hand, provide greater versatility for various workpiece sizes at a lower upfront cost, making them cost-effective for general-purpose applications despite potential compromises in clamping accuracy and repeatability. Evaluating the total cost of ownership and machining requirements is essential for selecting between collet and jaw chucks to optimize both expenditure and productivity in manufacturing operations.

Choosing the Right Chuck for Your Machining Needs

Choosing the right chuck for your machining needs depends on the precision and type of workpiece you handle. A collet chuck offers high concentricity and is ideal for gripping small, cylindrical objects with minimal runout, ensuring superior accuracy in applications like CNC machining. Jaw chucks provide versatility for gripping irregular or larger workpieces, making them suitable for general-purpose milling and turning tasks where adaptability is crucial.

Collet chuck vs jaw chuck Infographic

libmatt.com

libmatt.com