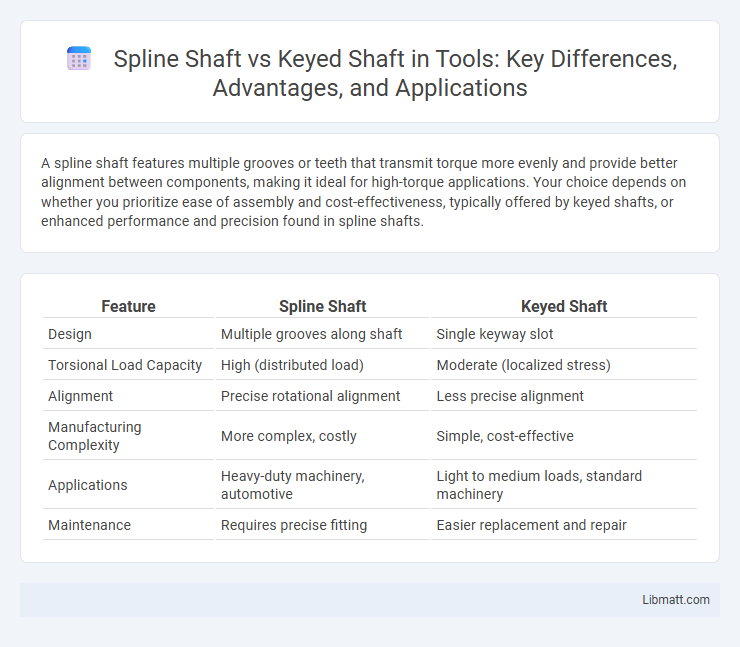

A spline shaft features multiple grooves or teeth that transmit torque more evenly and provide better alignment between components, making it ideal for high-torque applications. Your choice depends on whether you prioritize ease of assembly and cost-effectiveness, typically offered by keyed shafts, or enhanced performance and precision found in spline shafts.

Table of Comparison

| Feature | Spline Shaft | Keyed Shaft |

|---|---|---|

| Design | Multiple grooves along shaft | Single keyway slot |

| Torsional Load Capacity | High (distributed load) | Moderate (localized stress) |

| Alignment | Precise rotational alignment | Less precise alignment |

| Manufacturing Complexity | More complex, costly | Simple, cost-effective |

| Applications | Heavy-duty machinery, automotive | Light to medium loads, standard machinery |

| Maintenance | Requires precise fitting | Easier replacement and repair |

Introduction to Shaft Coupling Mechanisms

Spline shafts provide torque transmission through interlocking ridges or teeth that fit into corresponding grooves on mating components, ensuring precise alignment and load distribution. Keyed shafts transmit torque via a removable key inserted into keyways on both the shaft and the hub, allowing some axial movement but less effective load distribution compared to splines. Both mechanisms are essential in mechanical power transmission, with spline shafts favored for high-torque and precision applications while keyed shafts offer simplicity and ease of assembly.

What is a Spline Shaft?

A spline shaft is a mechanical component featuring multiple grooves or teeth that fit precisely into matching grooves on a mating part, enabling torque transmission without slippage. Unlike a keyed shaft, which relies on a single key inserted into a slot, the spline shaft distributes torque evenly across multiple points, enhancing load capacity and alignment accuracy. Your machinery benefits from spline shafts through improved power transfer, reduced wear, and precise rotational positioning.

What is a Keyed Shaft?

A keyed shaft is a mechanical component designed with a slot or groove, known as a keyway, that fits a corresponding key to transmit torque securely between the shaft and attached components like gears or pulleys. This design ensures precise alignment and prevents relative rotation, making it ideal for applications requiring reliable power transfer. Understanding the differences between a keyed shaft and a spline shaft helps you select the optimal solution for your mechanical system's torque and alignment needs.

Design Differences: Spline vs Keyed Shafts

Spline shafts feature multiple ridges or teeth that fit into corresponding grooves on a mating piece, providing uniform torque transmission and greater load distribution. Keyed shafts use a single key inserted into matching keyways on the shaft and hub, allowing for simpler manufacturing but less torque capacity and potential for stress concentration. The design difference impacts assembly precision, torque capacity, and durability in mechanical power transmission applications.

Strength and Torque Transmission Capabilities

Spline shafts provide superior strength and torque transmission capabilities compared to keyed shafts due to their multiple contact points along the shaft and hub interface. The even load distribution across splines reduces stress concentration, minimizing the risk of shaft failure under high torque conditions. Your machinery benefits from enhanced durability and torque transfer efficiency when using spline shafts in demanding applications.

Installation and Maintenance Considerations

Installation of spline shafts demands precise alignment to ensure torque transmission efficiency, reducing wear during operation, while keyed shafts offer easier installation but may suffer from backlash if not properly fitted. Maintenance of spline shafts typically involves regular lubrication and inspection for wear or deformation caused by stress concentrations around the splines, whereas keyed shafts require routine checks for keyway wear and potential key shear under high loads. Selecting between spline and keyed shafts depends on balancing the complexity of installation with long-term maintenance needs and mechanical performance requirements.

Applications: Where Each Shaft Type Excels

Spline shafts excel in high-torque automotive transmissions and aerospace systems, providing precise torque transfer with minimal backlash and easy axial movement. Keyed shafts are preferred in machinery and industrial equipment where quick assembly, cost-effectiveness, and straightforward torque transmission are essential. Each shaft type is optimized for specific load conditions and operational environments, with splines favored for complex, high-precision applications and keyed shafts for robust, general-purpose power transmission.

Cost Implications and Manufacturing Complexity

Spline shafts typically incur higher manufacturing costs due to intricate machining processes and precise tooling requirements, whereas keyed shafts offer a more cost-effective solution with simpler manufacturing techniques. The complexity of spline shafts results in longer production times and tighter tolerances, increasing overall expenses. Keyed shafts, with straightforward design and ease of assembly, reduce labor costs and are preferred for applications prioritizing budget and simplicity.

Durability and Wear Resistance Comparison

Spline shafts exhibit superior durability and wear resistance compared to keyed shafts due to their uniform load distribution across multiple contact surfaces, reducing stress concentration and minimizing wear. Keyed shafts experience higher localized stress at the keyway edges, leading to increased risk of deformation and fatigue over time. Materials used for spline shafts often incorporate advanced heat treatments or surface coatings that further enhance their operational longevity in demanding applications.

Choosing Between Spline and Keyed Shafts: Key Factors

Choosing between spline shafts and keyed shafts depends on torque transmission requirements, misalignment tolerance, and ease of assembly. Spline shafts provide higher torque capacity and better load distribution due to multiple contact points, making them ideal for high-performance applications. Keyed shafts offer simpler manufacturing and quicker repairs, suitable for moderate torque and standard alignment conditions.

Spline shaft vs keyed shaft Infographic

libmatt.com

libmatt.com