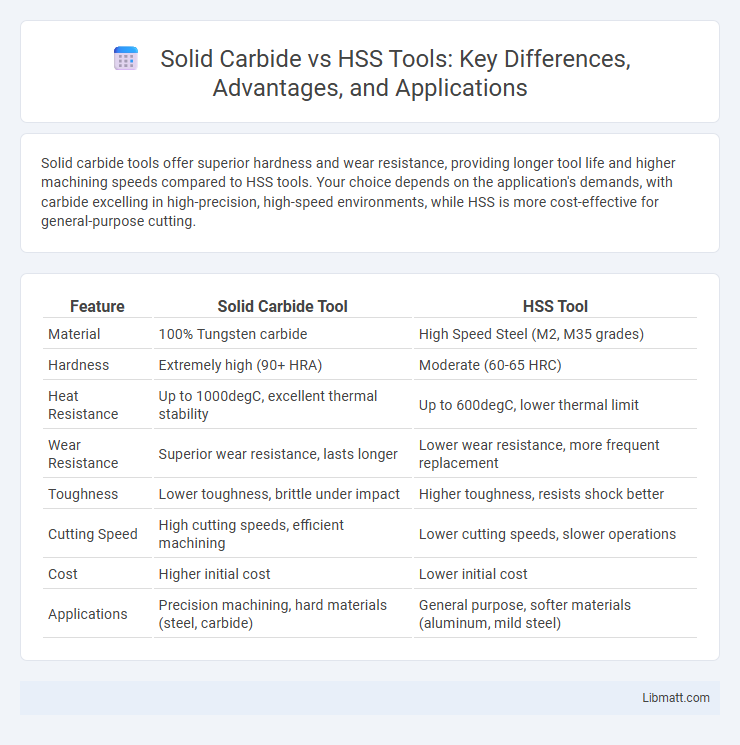

Solid carbide tools offer superior hardness and wear resistance, providing longer tool life and higher machining speeds compared to HSS tools. Your choice depends on the application's demands, with carbide excelling in high-precision, high-speed environments, while HSS is more cost-effective for general-purpose cutting.

Table of Comparison

| Feature | Solid Carbide Tool | HSS Tool |

|---|---|---|

| Material | 100% Tungsten carbide | High Speed Steel (M2, M35 grades) |

| Hardness | Extremely high (90+ HRA) | Moderate (60-65 HRC) |

| Heat Resistance | Up to 1000degC, excellent thermal stability | Up to 600degC, lower thermal limit |

| Wear Resistance | Superior wear resistance, lasts longer | Lower wear resistance, more frequent replacement |

| Toughness | Lower toughness, brittle under impact | Higher toughness, resists shock better |

| Cutting Speed | High cutting speeds, efficient machining | Lower cutting speeds, slower operations |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Precision machining, hard materials (steel, carbide) | General purpose, softer materials (aluminum, mild steel) |

Introduction to Cutting Tools

Solid carbide tools deliver superior hardness and wear resistance, enabling high-speed machining and longer tool life compared to High-Speed Steel (HSS) tools. HSS tools offer enhanced toughness and are more cost-effective, making them suitable for general-purpose cutting operations and materials with lower hardness. Selecting between solid carbide and HSS depends on machining requirements such as cutting speed, material hardness, and production volume.

What are Solid Carbide Tools?

Solid carbide tools are cutting instruments made from tungsten carbide particles bonded with a metallic binder, offering exceptional hardness and wear resistance compared to High-Speed Steel (HSS) tools. These tools deliver superior cutting speed and precision in machining operations, especially in high-temperature environments where HSS tools tend to lose hardness. Your choice of solid carbide tools can significantly enhance productivity and tool life in demanding industrial applications.

Understanding HSS (High Speed Steel) Tools

HSS (High Speed Steel) tools offer excellent toughness and resistance to impact, making them ideal for cutting softer metals and general-purpose machining. These tools maintain sharpness at high temperatures but have lower wear resistance compared to solid carbide, which limits their lifespan in high-speed or abrasive applications. Understanding your machining needs ensures you choose HSS for versatility and cost-effectiveness in moderate cutting speeds.

Key Differences: Solid Carbide vs. HSS Tools

Solid carbide tools offer superior hardness and wear resistance compared to HSS tools, resulting in longer tool life and higher cutting speeds. HSS tools provide greater toughness and flexibility, making them ideal for applications involving interrupted cuts or softer materials. Your choice depends on the required precision, material hardness, and machining conditions, with carbide excelling in high-performance tasks and HSS suited for versatile general-purpose use.

Performance and Cutting Speeds

Solid carbide tools deliver superior performance and significantly higher cutting speeds compared to HSS tools due to their hardness and heat resistance, making them ideal for high-precision machining. Your productivity increases as solid carbide tools maintain sharpness longer and withstand higher temperatures without deformation. HSS tools are suitable for lower-speed operations and softer materials, but solid carbide maximizes efficiency in demanding applications.

Tool Life and Durability

Solid carbide tools offer significantly longer tool life and superior durability compared to High-Speed Steel (HSS) tools due to their hardness and resistance to wear at high temperatures. While HSS tools tend to dull faster under continuous cutting operations, solid carbide maintains sharpness, enabling higher machining speeds and productivity. The enhanced toughness of carbide minimizes tool breakage and reduces downtime, making it ideal for industrial applications requiring precision and extended service life.

Cost Considerations

Solid carbide tools have a higher initial cost compared to HSS tools due to advanced material properties and manufacturing processes, but they offer longer tool life and superior wear resistance, which reduces the frequency of replacements and downtime. HSS tools are more affordable upfront and suitable for less demanding applications, but they tend to wear out faster, leading to increased tooling expenses over time. When evaluating cost considerations, manufacturers must balance the upfront investment of solid carbide tools against the total cost of ownership, including tool longevity and productivity gains.

Applications and Suitability

Solid carbide tools excel in high-speed machining, offering superior hardness and wear resistance ideal for cutting tough materials like stainless steel and titanium in aerospace and automotive industries. HSS tools provide excellent toughness and flexibility, making them suitable for slower cutting speeds and applications involving softer metals or intricate shapes, such as in woodworking or general-purpose drilling. The choice between solid carbide and HSS tools depends on specific machining requirements, including material hardness, cutting speed, and precision demands.

Advantages and Disadvantages

Solid carbide tools offer higher hardness and wear resistance compared to HSS tools, enabling faster machining speeds and longer tool life in cutting hard materials. However, carbide tools are more brittle and prone to chipping or fracture under heavy impact or interrupted cuts, making them less suitable for roughing operations. HSS tools provide better toughness and are easier to sharpen, but they wear out faster and cannot maintain cutting edge at high temperatures, limiting their efficiency in high-speed machining.

Choosing the Right Tool for Your Needs

Solid carbide tools offer superior hardness, wear resistance, and heat tolerance compared to HSS tools, making them ideal for high-speed machining and tougher materials like stainless steel or titanium. HSS tools provide better toughness and impact resistance, which suits applications involving interrupted cuts or softer metals like aluminum. Choosing the right tool for your needs depends on balancing cutting speed, material hardness, and tool life requirements to optimize performance and cost efficiency.

Solid carbide tool vs HSS tool Infographic

libmatt.com

libmatt.com