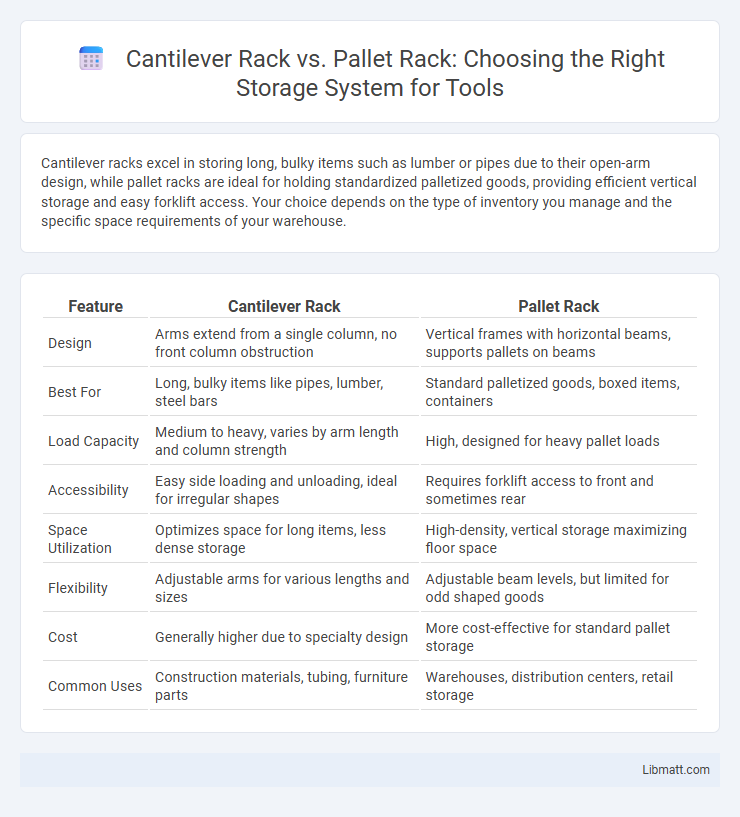

Cantilever racks excel in storing long, bulky items such as lumber or pipes due to their open-arm design, while pallet racks are ideal for holding standardized palletized goods, providing efficient vertical storage and easy forklift access. Your choice depends on the type of inventory you manage and the specific space requirements of your warehouse.

Table of Comparison

| Feature | Cantilever Rack | Pallet Rack |

|---|---|---|

| Design | Arms extend from a single column, no front column obstruction | Vertical frames with horizontal beams, supports pallets on beams |

| Best For | Long, bulky items like pipes, lumber, steel bars | Standard palletized goods, boxed items, containers |

| Load Capacity | Medium to heavy, varies by arm length and column strength | High, designed for heavy pallet loads |

| Accessibility | Easy side loading and unloading, ideal for irregular shapes | Requires forklift access to front and sometimes rear |

| Space Utilization | Optimizes space for long items, less dense storage | High-density, vertical storage maximizing floor space |

| Flexibility | Adjustable arms for various lengths and sizes | Adjustable beam levels, but limited for odd shaped goods |

| Cost | Generally higher due to specialty design | More cost-effective for standard pallet storage |

| Common Uses | Construction materials, tubing, furniture parts | Warehouses, distribution centers, retail storage |

Introduction to Cantilever Racks and Pallet Racks

Cantilever racks consist of horizontal arms attached to a single vertical column allowing for easy storage of long, bulky items such as lumber and pipes. Pallet racks feature upright frames with horizontal beams designed to store palletized goods, optimizing warehouse space by stacking pallets vertically. The choice between cantilever and pallet racks depends on the type of inventory, with cantilever racks suited for irregular items and pallet racks ideal for standardized pallet loads.

Key Differences Between Cantilever and Pallet Racks

Cantilever racks feature long horizontal arms without front columns, making them ideal for storing bulky, irregular-shaped items like pipes or lumber, while pallet racks consist of upright frames with horizontal beams designed to hold palletized goods. Cantilever racks offer open access and flexibility for wide or uneven loads, whereas pallet racks provide high-density storage optimized for standard pallets in warehouses. The key differences lie in structural design, load type suitability, and application efficiency for specific inventory types.

Structural Design Comparison

Cantilever racks feature a structural design with horizontal arms extending from vertical columns, allowing for easy storage of long or irregularly shaped items such as lumber and pipes without front columns obstructing access. Pallet racks use upright frames connected by horizontal beams to create bays where pallets are stored, optimizing space for standard palletized goods and providing high load capacity with clear visibility. Your choice depends on the nature of your inventory and space utilization, as cantilever racks excel in flexibility for bulky items, whereas pallet racks offer efficient, dense storage for uniform products.

Storage Applications and Use Cases

Cantilever racks provide optimal storage for long, bulky items like lumber, pipes, and metal bars due to their open design and adjustable arms, allowing easy loading and access. Pallet racks are ideal for storing palletized goods and heavy inventory, enabling efficient use of vertical space in warehouses with standardized products. Your choice depends on the type of materials being stored and the handling equipment used in your warehouse operations.

Load Capacity and Weight Distribution

Cantilever racks excel in handling long, bulky items with uneven weight distribution, offering superior load capacity through their open-front design and adjustable arms. Pallet racks are optimized for uniform loads on pallets, providing consistent weight distribution across beams and uprights for heavy-duty storage. Choosing the right system depends on your inventory's load characteristics and weight distribution needs for maximum efficiency.

Space Efficiency and Accessibility

Cantilever racks maximize space efficiency by allowing easy storage of long, bulky items without front columns, enabling full arm access and optimal horizontal utilization. Pallet racks are designed for high-density storage of standardized pallets, using vertical space efficiently but often limiting individual pallet access due to aisle requirements. Accessibility in cantilever racks is superior for irregular items since each arm is independently reachable, while pallet racks require forklifts and aisle space for pallet extraction, impacting quick access.

Installation and Maintenance Requirements

Cantilever racks offer easier installation due to their simple, modular design, allowing quick assembly without the need for extensive tools or specialized labor. Pallet racks require more precise floor anchoring and periodic inspections to maintain structural integrity, especially in high-traffic warehouse environments. Your maintenance routine should account for cantilever racks' exposure to arm damage, while pallet racks demand regular checking of beam connections and load capacity compliance.

Cost Considerations

Cantilever racks typically involve higher initial costs due to their specialized design for storing long or irregularly shaped items, whereas pallet racks offer a more cost-effective solution for general bulk storage needs. Your choice should factor in the specific type of inventory, as pallet racks provide better space utilization and scalability, often reducing long-term expenses. Maintenance and customization expenses also vary, with cantilever racks requiring more investment if adjustments or expansions are necessary.

Safety Considerations

Cantilever racks offer enhanced safety for storing long, bulky items by eliminating front posts and reducing collision risks, while pallet racks provide secure support for heavy palletized loads with robust beam and column designs. Your choice should consider the specific load types and warehouse traffic, as cantilever racks allow easier access but require careful anchoring for stability. Proper installation, regular inspections, and adherence to load capacity are critical safety considerations for both rack systems to prevent accidents and structural failures.

Choosing the Right Rack System for Your Warehouse

Choosing the right rack system for your warehouse depends on the types of products you store and the space available. Cantilever racks are ideal for storing long, bulky items such as lumber, pipes, or metal bars, providing easy access and flexibility. Pallet racks are designed for palletized goods, maximizing vertical storage and improving organization for standard-sized inventory.

Cantilever rack vs pallet rack Infographic

libmatt.com

libmatt.com