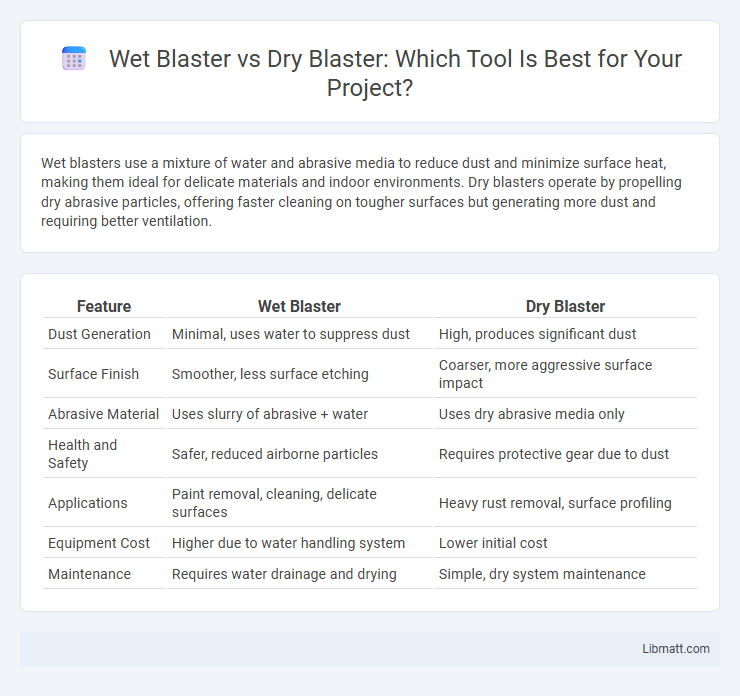

Wet blasters use a mixture of water and abrasive media to reduce dust and minimize surface heat, making them ideal for delicate materials and indoor environments. Dry blasters operate by propelling dry abrasive particles, offering faster cleaning on tougher surfaces but generating more dust and requiring better ventilation.

Table of Comparison

| Feature | Wet Blaster | Dry Blaster |

|---|---|---|

| Dust Generation | Minimal, uses water to suppress dust | High, produces significant dust |

| Surface Finish | Smoother, less surface etching | Coarser, more aggressive surface impact |

| Abrasive Material | Uses slurry of abrasive + water | Uses dry abrasive media only |

| Health and Safety | Safer, reduced airborne particles | Requires protective gear due to dust |

| Applications | Paint removal, cleaning, delicate surfaces | Heavy rust removal, surface profiling |

| Equipment Cost | Higher due to water handling system | Lower initial cost |

| Maintenance | Requires water drainage and drying | Simple, dry system maintenance |

Introduction to Wet and Dry Blasting

Wet blasting utilizes a mixture of water and abrasive media to clean surfaces, reducing dust and heat generation, which makes it ideal for delicate materials and precision cleaning. Dry blasting relies solely on abrasive media propelled by compressed air, offering higher impact force suitable for tough surface preparation and heavy-duty cleaning. Both methods are essential in industries like automotive, aerospace, and manufacturing, with wet blasting favored for rust removal and dry blasting preferred for paint stripping and roughening surfaces.

How Wet Blasting Works

Wet blasting uses a mixture of water, abrasive media, and compressed air to clean or finish surfaces, effectively reducing dust and heat during the process. The combination of water and abrasive particles propels at high velocity, providing a gentler abrasion than dry blasting while minimizing surface damage. This method enhances cohesion of the abrasive, resulting in improved cleaning efficiency and a more controlled finish on metals, plastics, and composites.

How Dry Blasting Works

Dry blasting works by propelling abrasive materials through a high-pressure air stream to clean or etch surfaces without moisture. Unlike wet blasting, which uses water mixed with abrasives, dry blasting relies solely on dry grit, allowing for faster drying times and reduced surface contamination. Your choice depends on the material sensitivity and desired finish, as dry blasting excels in precision and speed for tougher cleaning tasks.

Key Differences Between Wet and Dry Blasters

Wet blasters use a mixture of water and abrasive media to clean surfaces, reducing dust and minimizing surface heat, whereas dry blasters rely solely on abrasive particles propelled by compressed air, generating more dust and potential surface heat. Wet blasting is ideal for delicate or heat-sensitive materials due to its cooling effects, while dry blasting suits tougher applications where moisture could damage the workpiece. Your choice between wet and dry blasters should consider environmental impact, surface condition, and desired finish quality.

Surface Finish Quality Comparison

Wet blasters deliver superior surface finish quality by using a water and abrasive mixture that reduces dust and heat, minimizing surface damage and producing a smoother, cleaner result. Dry blasters may cause more surface roughness and embedded dust due to higher friction and heat generation during the blasting process. For your projects requiring precision and a refined finish, wet blasting offers enhanced control and better protection of delicate surfaces.

Equipment and Maintenance Requirements

Wet blasters require specialized equipment including water containment systems, pumps, and moisture-resistant air compressors, which demand regular inspection to prevent rust and corrosion. Dry blasters operate with simpler setups involving only compressed air and abrasive media but need frequent filter and moisture trap maintenance to avoid equipment clogging. Both systems necessitate routine cleaning and component replacement to ensure optimal performance and longevity.

Environmental and Safety Considerations

Wet blasters significantly reduce airborne dust by utilizing water to suppress particles, leading to improved air quality and safer working conditions compared to dry blasters, which can generate harmful dust clouds. The water in wet blasting minimizes the risk of inhaling hazardous materials, lowering respiratory health hazards for operators. Additionally, wet blasting reduces the chance of fire or explosion by dampening combustible dust, making it a safer option in sensitive environments.

Cost Analysis: Wet Blasting vs Dry Blasting

Wet blasting generally incurs higher upfront costs due to water reclamation systems and specialized equipment, but it reduces overall maintenance expenses by minimizing dust and equipment wear. Dry blasting equipment tends to be less expensive initially but often leads to increased cleanup costs and consumable abrasive usage. You can optimize your budget by considering the total lifecycle costs, including labor, waste disposal, and environmental compliance associated with each method.

Ideal Applications for Wet and Dry Blasting

Wet blasting is ideal for delicate surfaces and applications requiring minimal dust production, such as automotive restorations, aerospace components, and sensitive electronic parts cleaning. Dry blasting suits heavy-duty tasks like rust removal, paint stripping, and metal surface preparation due to its strong abrasive impact and ease of use in outdoor environments. Your choice depends on the material's fragility and environmental conditions, with wet blasting offering gentler cleaning and dry blasting providing aggressive surface treatment.

Choosing the Right Blasting Method for Your Needs

Wet blasters use water mixed with abrasive media to reduce dust and minimize surface heat, making them ideal for delicate materials and indoor applications. Dry blasters operate with compressed air and dry abrasive, offering faster removal rates and suitability for tougher surfaces or outdoor jobs. Consider your project's material sensitivity, required finish, and environmental constraints to determine whether a wet blaster or dry blaster best meets your needs.

Wet blaster vs dry blaster Infographic

libmatt.com

libmatt.com