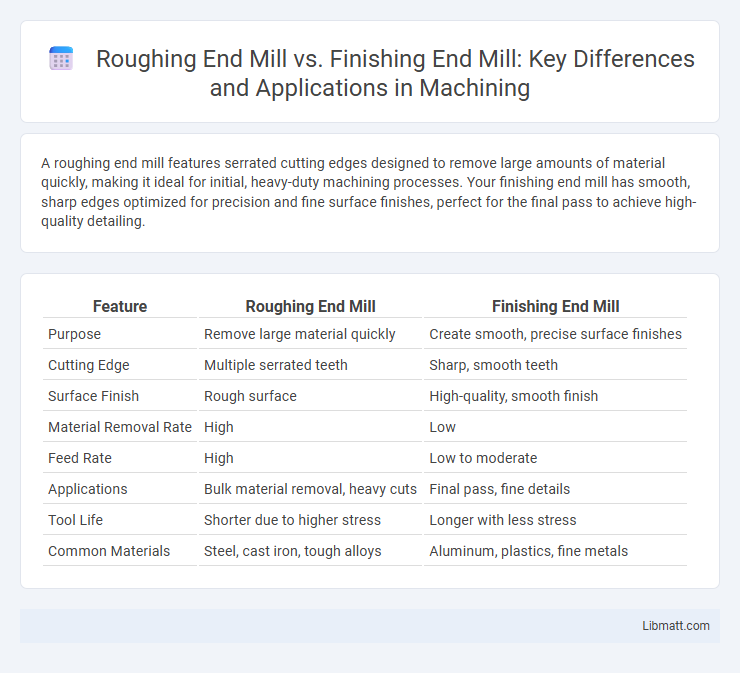

A roughing end mill features serrated cutting edges designed to remove large amounts of material quickly, making it ideal for initial, heavy-duty machining processes. Your finishing end mill has smooth, sharp edges optimized for precision and fine surface finishes, perfect for the final pass to achieve high-quality detailing.

Table of Comparison

| Feature | Roughing End Mill | Finishing End Mill |

|---|---|---|

| Purpose | Remove large material quickly | Create smooth, precise surface finishes |

| Cutting Edge | Multiple serrated teeth | Sharp, smooth teeth |

| Surface Finish | Rough surface | High-quality, smooth finish |

| Material Removal Rate | High | Low |

| Feed Rate | High | Low to moderate |

| Applications | Bulk material removal, heavy cuts | Final pass, fine details |

| Tool Life | Shorter due to higher stress | Longer with less stress |

| Common Materials | Steel, cast iron, tough alloys | Aluminum, plastics, fine metals |

Introduction to End Mills

End mills are cutting tools used in milling machines for shaping materials such as metal and wood. Roughing end mills feature serrated cutting edges designed to remove large amounts of material quickly, making them ideal for initial, heavy-duty cuts. Finishing end mills have smooth, sharp edges suited for precision work and producing fine surface finishes after roughing operations.

What is a Roughing End Mill?

A roughing end mill, also known as a hog mill, is designed for rapidly removing large amounts of material during the initial stages of machining. It features serrated cutting edges that break up chips into smaller pieces, reducing cutting forces and heat buildup for more efficient heavy-duty milling. Compared to finishing end mills, roughing end mills prioritize material removal rate over surface finish quality.

What is a Finishing End Mill?

A finishing end mill is a precision cutting tool designed to create smooth surfaces and fine details on a workpiece after roughing operations. It features a higher number of flutes and a sharper cutting edge, enabling it to produce tight tolerances and excellent surface finishes in materials like aluminum, steel, and composites. Your choice of a finishing end mill ensures superior surface quality and dimensional accuracy in the final machining process.

Key Differences Between Roughing and Finishing End Mills

Roughing end mills feature serrated cutting edges designed to remove large amounts of material quickly, making them ideal for heavy-duty machining and reducing cycle time. Finishing end mills have smooth, sharp edges that provide superior surface finish and dimensional accuracy, perfect for final passes and detail work. Your choice depends on whether the priority is efficient material removal or achieving a precise, polished surface.

Material Removal Rates: Roughing vs Finishing

Roughing end mills achieve significantly higher material removal rates due to their robust tooth design and deeper cuts, making them ideal for rapid stock removal in heavy machining operations. Finishing end mills, with finer cutting edges and shallower depths of cut, prioritize precision and surface finish over speed, resulting in lower material removal rates. Choosing between the two depends on balancing machining efficiency with the desired surface quality and dimensional accuracy.

Surface Finish Quality Comparison

Roughing end mills generate a coarser surface finish due to their serrated teeth designed for rapid material removal, resulting in visible scallops and tool marks. Finishing end mills produce a smoother, more precise surface finish with finer cuts, ideal for detailed final shaping and high-quality polishing. Choosing the right end mill impacts your project's surface quality, ensuring that finishing tools are preferred for superior finish standards.

Tool Geometry and Design Variations

Roughing end mills feature serrated or spiked cutting edges designed to remove large amounts of material quickly with reduced cutting forces, while finishing end mills have smooth, sharp edges optimized for precise surface finishes and tight tolerances. The tool geometry of roughing end mills often includes a greater helix angle and chip breaker teeth to manage heavy cuts and enhance chip evacuation. Finishing end mills vary in flute count and radius to achieve fine detail and minimal surface roughness, guiding your tool selection based on the specific machining phase.

Typical Applications for Roughing End Mills

Roughing end mills are designed for heavy material removal in applications such as mold making, die sinking, and machining large metal blocks where rapid stock removal is essential. These tools excel in rough shaping of steel, cast iron, and other tough materials by efficiently breaking chips and reducing cutting forces. Your choice of a roughing end mill enhances productivity by preparing the workpiece for subsequent finishing passes that require finer surface finishes.

Typical Applications for Finishing End Mills

Finishing end mills are primarily used for creating smooth surface finishes and precise dimensional accuracy in the final machining stages. Typical applications include fine contouring, mold and die work, and machining of aerospace components where tight tolerances are critical. These tools excel in producing polished edges and detailed features on materials like stainless steel, aluminum, and titanium.

Choosing the Right End Mill for Your Milling Project

Selecting the right end mill for your milling project hinges on understanding the distinct roles of roughing and finishing end mills. Roughing end mills, designed with serrated edges, rapidly remove large amounts of material and prepare the workpiece for detailed shaping. Finishing end mills offer smooth, precise cuts that enhance surface quality and dimensional accuracy, ensuring your final product meets exact specifications.

Roughing end mill vs finishing end mill Infographic

libmatt.com

libmatt.com