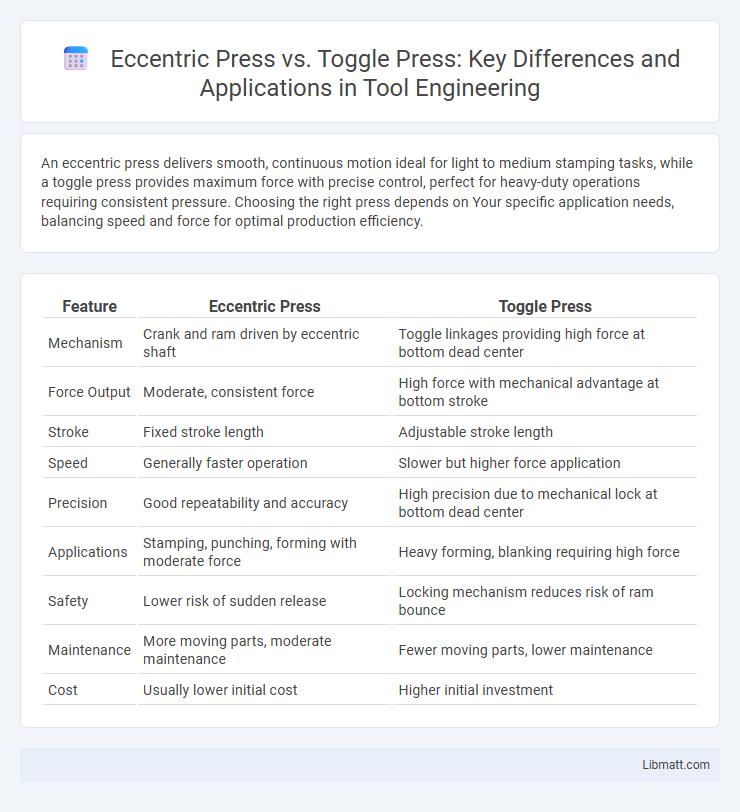

An eccentric press delivers smooth, continuous motion ideal for light to medium stamping tasks, while a toggle press provides maximum force with precise control, perfect for heavy-duty operations requiring consistent pressure. Choosing the right press depends on Your specific application needs, balancing speed and force for optimal production efficiency.

Table of Comparison

| Feature | Eccentric Press | Toggle Press |

|---|---|---|

| Mechanism | Crank and ram driven by eccentric shaft | Toggle linkages providing high force at bottom dead center |

| Force Output | Moderate, consistent force | High force with mechanical advantage at bottom stroke |

| Stroke | Fixed stroke length | Adjustable stroke length |

| Speed | Generally faster operation | Slower but higher force application |

| Precision | Good repeatability and accuracy | High precision due to mechanical lock at bottom dead center |

| Applications | Stamping, punching, forming with moderate force | Heavy forming, blanking requiring high force |

| Safety | Lower risk of sudden release | Locking mechanism reduces risk of ram bounce |

| Maintenance | More moving parts, moderate maintenance | Fewer moving parts, lower maintenance |

| Cost | Usually lower initial cost | Higher initial investment |

Introduction to Eccentric and Toggle Presses

Eccentric presses use a crank mechanism to convert rotary motion into linear motion, providing consistent force ideal for precise metal forming and cutting tasks. Toggle presses employ a toggle linkage system that amplifies force at the bottom of the stroke, making them suitable for high-force stamping and punching operations. Both types of presses are essential in manufacturing, with eccentric presses favoring speed and toggle presses emphasizing maximum press force.

Core Mechanisms of Eccentric Press

The core mechanism of an eccentric press involves a rotating eccentric cam converting rotary motion into linear press action, enabling smooth and consistent force application. This design allows precise control over stroke length and speed, making it ideal for stamping, punching, and forming operations. Your manufacturing process benefits from the energy-efficient, reliable, and low-maintenance nature of eccentric presses compared to toggle press mechanisms.

Core Mechanisms of Toggle Press

The core mechanism of a toggle press relies on a toggle linkage system that multiplies force by converting low input effort into high output pressure, ideal for precision stamping and forming operations. Unlike eccentric presses which use a crankshaft to generate motion, toggle presses lock at the bottom dead center, providing consistent tonnage and improved safety during the press cycle. Your choice between these presses depends on the specific force requirements and operational control desired for manufacturing processes.

Key Differences Between Eccentric and Toggle Presses

Eccentric presses utilize an offset crank mechanism to convert rotary motion into precise linear force, offering consistent stroke speed and force control ideal for metal forming. Toggle presses operate through linked arms creating a toggle action that generates high clamping force near the bottom of the stroke while maintaining low energy consumption. The main difference lies in force delivery: eccentric presses provide uniform pressure throughout the stroke, whereas toggle presses concentrate force at the end, making each suitable for specific manufacturing processes.

Advantages of Eccentric Presses

Eccentric presses offer precise control over ram speed and stroke length, making them ideal for high-accuracy stamping and forming operations. Their mechanical simplicity ensures lower maintenance costs and greater reliability compared to toggle presses. You benefit from smoother operation and consistent force application, which enhances product quality and reduces material waste.

Advantages of Toggle Presses

Toggle presses offer higher precision and consistency compared to eccentric presses, making them ideal for applications requiring accurate and repetitive stamping or forming. Their mechanical advantage allows for greater force with less input energy, enhancing efficiency and reducing operator fatigue. Toggle presses also provide improved safety features, ensuring better control during operation, which can significantly benefit your manufacturing process.

Typical Industrial Applications

Eccentric presses are commonly used in applications requiring high precision and moderate force, such as metal stamping, punching, and forming small to medium-sized components in the automotive and appliance industries. Toggle presses excel in high-force, low-speed operations like blanking, punching large sheet metals, and assembling heavy parts, frequently found in aerospace and heavy machinery manufacturing. Both presses serve distinct roles where eccentric presses prioritize accuracy and speed, while toggle presses focus on heavy-duty forging and pressing tasks.

Energy Efficiency Comparison

Eccentric presses typically consume more energy due to continuous motor operation, while toggle presses use stored mechanical energy in the toggle mechanism, resulting in higher energy efficiency during stamping processes. Toggle presses convert electrical power into mechanical advantage more effectively, reducing power consumption for repetitive tasks with consistent force requirements. Energy efficiency in toggle presses leads to reduced operational costs and lower environmental impact compared to the continuously powered eccentric press systems.

Maintenance and Longevity

Eccentric presses typically require more frequent maintenance due to their mechanical complexity and higher wear on moving parts, impacting their long-term durability. Toggle presses, designed with fewer moving components and simpler mechanisms, offer enhanced longevity and reduced downtime, making them cost-effective for high-volume production. You can extend the lifespan of either machine by adhering to regular maintenance schedules and using quality lubricants tailored to the press type.

Choosing the Right Press for Your Needs

Eccentric presses offer precise control and are ideal for applications requiring consistent force and accurate positioning, commonly used in metal forming and punching tasks. Toggle presses deliver high tonnage with minimal effort, making them suitable for heavy-duty stamping and forming where high speed and force are essential. Selecting the right press depends on the specific production requirements, including force needed, cycle speed, and part complexity.

Eccentric press vs toggle press Infographic

libmatt.com

libmatt.com