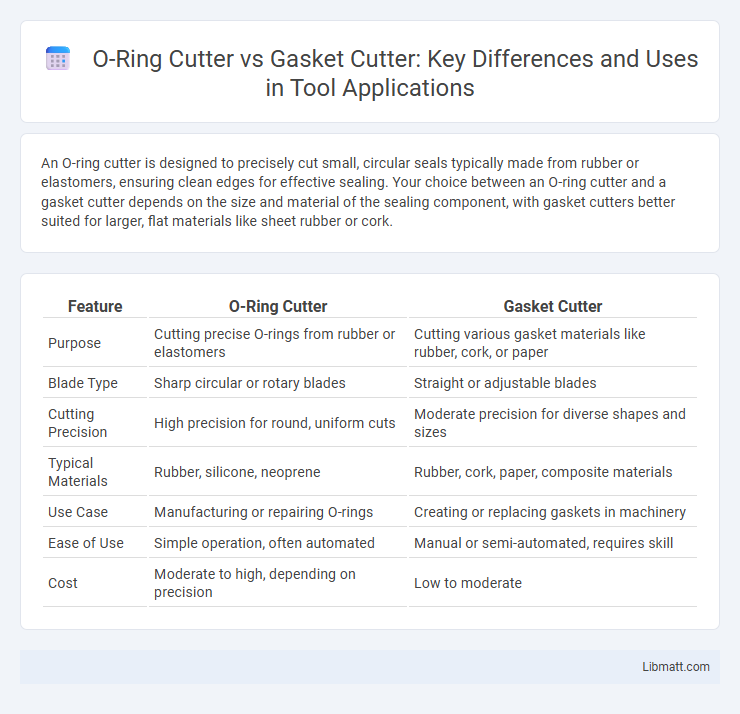

An O-ring cutter is designed to precisely cut small, circular seals typically made from rubber or elastomers, ensuring clean edges for effective sealing. Your choice between an O-ring cutter and a gasket cutter depends on the size and material of the sealing component, with gasket cutters better suited for larger, flat materials like sheet rubber or cork.

Table of Comparison

| Feature | O-Ring Cutter | Gasket Cutter |

|---|---|---|

| Purpose | Cutting precise O-rings from rubber or elastomers | Cutting various gasket materials like rubber, cork, or paper |

| Blade Type | Sharp circular or rotary blades | Straight or adjustable blades |

| Cutting Precision | High precision for round, uniform cuts | Moderate precision for diverse shapes and sizes |

| Typical Materials | Rubber, silicone, neoprene | Rubber, cork, paper, composite materials |

| Use Case | Manufacturing or repairing O-rings | Creating or replacing gaskets in machinery |

| Ease of Use | Simple operation, often automated | Manual or semi-automated, requires skill |

| Cost | Moderate to high, depending on precision | Low to moderate |

Introduction to O-Ring Cutters and Gasket Cutters

O-ring cutters are precision tools designed specifically to cut circular rubber seals with smooth edges, ensuring airtight and watertight seals in mechanical applications. Gasket cutters, on the other hand, are versatile tools used to cut various gasket materials like rubber, cork, or fiber sheets into custom shapes or sizes for sealing flanges and joints. Understanding the distinct functions of O-ring cutters and gasket cutters helps you select the right tool for efficient sealing and maintenance tasks.

Purpose and Applications of O-Ring Cutters

O-ring cutters are specifically designed for precision cutting of rubber O-rings, ensuring smooth edges and accurate sizing essential for sealing applications in automotive, plumbing, and industrial machinery. These cutters enable you to create custom O-rings that provide reliable seals, preventing fluid leaks and maintaining system integrity under pressure. Unlike gasket cutters, which handle flat sheet materials for creating larger seals, O-ring cutters focus on the precise, circular profile critical for dynamic and static sealing uses.

Common Uses of Gasket Cutters

Gasket cutters are designed primarily for cutting flat sheet materials like rubber, cork, and fiber to create custom gaskets for sealing applications in engines, pumps, and pipe flanges. Their precision and ability to produce smooth, accurate edges make them ideal for ensuring airtight and watertight seals in industrial and automotive settings. You can rely on gasket cutters to enhance the durability and performance of your sealing components by delivering consistently clean cuts.

Design Differences: O-Ring vs Gasket Cutters

O-ring cutters feature sharp, precision blades designed to slice cleanly through rubber seals without distortion, while gasket cutters typically have broader, flat blades optimized for cutting spreading materials like cork or fiber sheets. The design difference lies in the blade shape and cutting angle; O-ring cutters prioritize accuracy to maintain seal integrity, whereas gasket cutters emphasize versatility to handle varying material thicknesses. Your choice between these tools should align with the specific material and cutting precision required for sealing applications.

Materials Compatible with O-Ring and Gasket Cutters

O-ring cutters are designed to work with softer, more flexible materials such as rubber, silicone, and elastomers commonly used in sealing applications. Gasket cutters handle a broader range of materials including cork, fiber, rubber, and composite sheets, making them suitable for thicker and more rigid gasket materials. Understanding the material compatibility of your cutter ensures clean, precise cuts tailored to the specific sealing components you work with.

Precision and Accuracy: Which Tool Excels?

O-ring cutters are specifically designed to provide high precision and accuracy when cutting small, circular rubber seals, ensuring a clean and exact fit critical for sealing applications. Gasket cutters, while versatile and able to handle larger, irregular shapes, generally offer less precision due to their broader cutting edges and adaptability to various materials. For applications requiring tight tolerances and exact dimensions, O-ring cutters excel in delivering superior precision and accuracy compared to gasket cutters.

Ease of Use and User Experience

O-ring cutters typically offer greater precision and control due to their smaller blade and ergonomic design, making them easier for detailed cuts on rubber materials. Gasket cutters, often equipped with larger blades and adjustable settings, are designed for cutting thicker and tougher materials but may require more skill to achieve clean edges. User experience varies as O-ring cutters suit intricate work with minimal effort, while gasket cutters demand steadier handling and practice for optimal results.

Cost Considerations Between O-Ring and Gasket Cutters

O-ring cutters typically come at a lower cost due to their simpler design and specialized use for smaller, precise cuts, while gasket cutters are generally more expensive because they accommodate larger, thicker materials and offer versatility for various gasket shapes. Investing in a gasket cutter can save Your business money in the long run by reducing material waste and improving cutting accuracy for larger projects. Choosing the right cutter depends on balancing initial cost with the specific cutting needs and volume of Your applications.

Maintenance and Durability Comparison

O-ring cutters are typically designed with precision blades that maintain sharpness longer, reducing the need for frequent replacements and ensuring consistent cuts on resilient elastomer materials. Gasket cutters, often made with heavier-duty components, can endure tougher industrial environments but may require more maintenance due to blade wear from cutting thicker, multi-layered gasket materials. Your choice between the two should consider how often you need to perform cuts and the specific durability requirements of your maintenance tasks.

Choosing the Right Cutter for Your Application

Selecting the right cutter for your application depends on the material and shape you need to cut; O-ring cutters are designed specifically to create precise, round cross-sections suitable for O-rings, while gasket cutters are intended for flat, often irregular shapes used in sealing flanges and surfaces. Your choice impacts the efficiency and accuracy of the sealing component fabrication, where an O-ring cutter ensures uniformity in circular seals and a gasket cutter provides versatility in cutting various gasket profiles from sheets. Understanding these differences helps optimize material use and ensures durability in sealing performance.

O-ring cutter vs gasket cutter Infographic

libmatt.com

libmatt.com