A fixed vice provides a stable, immovable clamping solution ideal for precision tasks requiring firm hold, while a swivel vice offers rotational flexibility, allowing you to adjust the angle of the workpiece for enhanced accessibility and versatility. Choosing between the two depends on whether your work prioritizes stability or maneuverability.

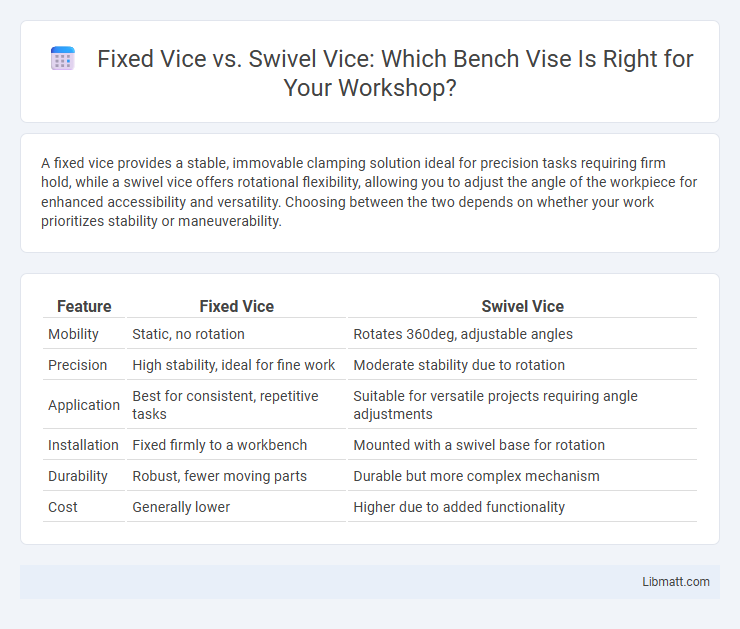

Table of Comparison

| Feature | Fixed Vice | Swivel Vice |

|---|---|---|

| Mobility | Static, no rotation | Rotates 360deg, adjustable angles |

| Precision | High stability, ideal for fine work | Moderate stability due to rotation |

| Application | Best for consistent, repetitive tasks | Suitable for versatile projects requiring angle adjustments |

| Installation | Fixed firmly to a workbench | Mounted with a swivel base for rotation |

| Durability | Robust, fewer moving parts | Durable but more complex mechanism |

| Cost | Generally lower | Higher due to added functionality |

Introduction to Fixed and Swivel Vices

Fixed vices feature a rigid, immovable design that provides maximum stability for precision clamping in woodworking and metalworking. Swivel vices incorporate a rotating base, allowing the clamping angle to be adjusted up to 360 degrees for enhanced versatility during complex tasks. Choosing between fixed and swivel vices depends on the requirement for stability versus maneuverability in various machining or assembly operations.

Key Features of Fixed Vices

Fixed vices feature a sturdy, immovable base that provides maximum stability and precision during clamping tasks, making them ideal for heavy-duty applications like metalworking and woodworking. Their rigid design ensures consistent alignment and enhanced durability compared to swivel vices, which offer adjustable angles but less rigidity. The absence of rotation in fixed vices minimizes movement, resulting in superior grip strength and safety during high-pressure operations.

Key Features of Swivel Vices

Swivel vices feature a rotating base that allows 360-degree movement, offering exceptional flexibility for positioning workpieces at various angles. They are equipped with a locking mechanism to secure the swivel base firmly in place, ensuring stability during use. Unlike fixed vices, swivel vices provide enhanced versatility for complex tasks such as metalworking, woodworking, and assembly.

Material Compatibility and Applications

Fixed vices excel in heavy-duty tasks with materials like steel and cast iron due to their robust, rigid construction, providing maximum stability. Swivel vices offer enhanced versatility for softer materials such as wood and plastic, allowing precise angle adjustments in applications like woodworking and light metalwork. Choosing the appropriate vice depends on the material hardness and the need for angular flexibility during the clamping process.

Precision and Stability Comparison

Fixed vices provide superior stability and precision due to their rigid, non-movable base, ensuring minimal movement during machining or assembly tasks. Swivel vices offer versatility with their adjustable orientation but may sacrifice some precision and stability compared to fixed vices because of the rotating mechanism. For applications requiring exact alignment and firm clamping, fixed vices are typically preferred, whereas swivel vices are suited for tasks needing adjustable positioning.

Flexibility and Versatility in Use

A swivel vice provides superior flexibility and versatility compared to a fixed vice by allowing 360-degree rotation, enabling you to position workpieces at various angles for precise machining and assembly tasks. Fixed vices offer stability and strength for heavy-duty clamping but lack the ability to adjust orientation without repositioning the entire tool. Choosing a swivel vice enhances your workshop's adaptability by accommodating diverse projects with ease.

Ease of Installation and Maintenance

Fixed vises offer straightforward installation with a solid base that requires bolting directly to a workbench, ensuring maximum stability and minimal movement during use. Maintenance for fixed vises is simple, involving regular lubrication of the screw mechanism and periodic cleaning to prevent metal debris buildup. Swivel vises require more complex installation due to their rotating base, necessitating precise alignment and secure fastening to allow smooth swivel functionality, while maintenance includes both lubrication of the screw and the swivel joint to maintain optimal performance.

Cost Differences and Value for Money

Fixed vices generally have a lower initial cost compared to swivel vices due to their simpler design and fewer moving parts, making them an economical choice for basic clamping needs. Swivel vices offer enhanced versatility by allowing rotation for better positioning, which justifies their higher price with increased productivity and adaptability in complex tasks. Evaluating cost differences involves weighing the upfront investment against long-term value, where swivel vices provide greater functionality and potential savings in labor time despite higher purchase prices.

Choosing the Right Vice for Your Workshop

Choosing the right vice for your workshop depends on the type of tasks you frequently perform, where a fixed vice offers superior stability and strength for heavy-duty projects, ensuring your workpiece remains firmly in place. In contrast, a swivel vice provides versatility with a rotating base, allowing you to adjust angles and access different sides without removing the workpiece, which is ideal for precision tasks and complex assemblies. Your decision should balance the need for rigidity versus flexibility, optimizing productivity and comfort based on the specific demands of your projects.

Conclusion: Fixed Vice or Swivel Vice?

A fixed vice provides superior stability and strength for precision tasks, making it ideal for heavy-duty applications requiring a firm grip. A swivel vice offers enhanced versatility with its 360-degree rotation, allowing easier position adjustments for complex angles and repetitive operations. Choosing between a fixed or swivel vice depends on whether stability or flexibility is the priority in your specific woodworking or metalworking projects.

Fixed vice vs swivel vice Infographic

libmatt.com

libmatt.com