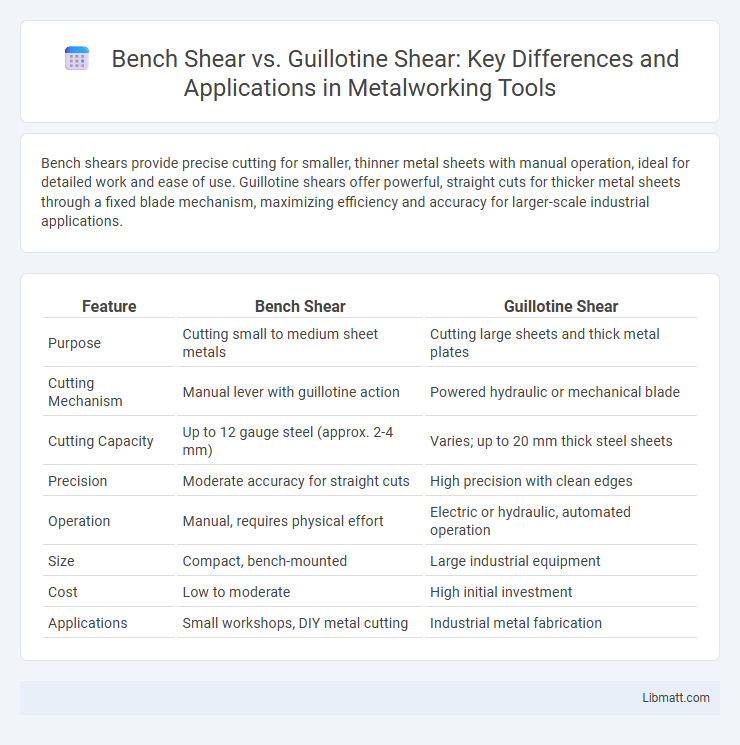

Bench shears provide precise cutting for smaller, thinner metal sheets with manual operation, ideal for detailed work and ease of use. Guillotine shears offer powerful, straight cuts for thicker metal sheets through a fixed blade mechanism, maximizing efficiency and accuracy for larger-scale industrial applications.

Table of Comparison

| Feature | Bench Shear | Guillotine Shear |

|---|---|---|

| Purpose | Cutting small to medium sheet metals | Cutting large sheets and thick metal plates |

| Cutting Mechanism | Manual lever with guillotine action | Powered hydraulic or mechanical blade |

| Cutting Capacity | Up to 12 gauge steel (approx. 2-4 mm) | Varies; up to 20 mm thick steel sheets |

| Precision | Moderate accuracy for straight cuts | High precision with clean edges |

| Operation | Manual, requires physical effort | Electric or hydraulic, automated operation |

| Size | Compact, bench-mounted | Large industrial equipment |

| Cost | Low to moderate | High initial investment |

| Applications | Small workshops, DIY metal cutting | Industrial metal fabrication |

Introduction to Bench Shear and Guillotine Shear

Bench shears and guillotine shears are essential metal cutting tools used in fabrication and manufacturing processes. Bench shears offer precise, manual cutting for small to medium-sized metal sheets, providing control and ease of use in workshop settings. Guillotine shears deliver powerful, straight cutting action for larger sheet metal, utilizing a fixed blade and moving blade mechanism for high-volume or heavy-duty applications.

Basic Working Principles

Bench shear operates by manually applying force via a lever to cut metal, using a stationary blade against a moving blade to shear material with precision. Guillotine shear employs a powered reciprocating blade that descends vertically to cut through thicker metal sheets by exerting high mechanical pressure evenly across the blade's length. The bench shear suits lighter, smaller tasks while the guillotine shear handles heavier, industrial-scale metal cutting with higher efficiency and consistency.

Design and Construction Differences

Bench shear features a compact, manually operated design with a fixed lower blade and a single upper blade that swings down to shear materials, making it ideal for small-scale or precise cutting tasks. Guillotine shear employs a robust frame with a straight, downward-moving upper blade and a stationary lower blade, designed for heavy-duty, high-volume sheet metal cutting with consistent, clean edges. Your choice between these tools depends on the precision required and the volume of work, as bench shears offer portability and simplicity, while guillotine shears provide strength and efficiency for industrial applications.

Material Types and Thicknesses Each Can Handle

Bench shears excel in cutting lighter materials such as thin sheet metal, plastics, and soft metals up to approximately 2 mm thickness, ideal for precise trimming tasks. Guillotine shears handle a broader range of materials including steel plates and thicker metals, typically cutting thicknesses from 3 mm up to 20 mm or more, depending on the machine's capacity. Material hardness and thickness dictate the shear choice, with bench shears suited for delicate, thin materials and guillotine shears optimized for heavy-duty, thicker sheets.

Precision and Cutting Accuracy

Bench shears provide high precision and cutting accuracy for thinner materials and detailed work due to their manual control and fine adjustment capabilities. Guillotine shears excel in cutting thicker sheets with consistent, straight cuts, ideal for rapid production but may have slightly less fine accuracy on delicate tasks. Your choice depends on the balance between the need for precise, intricate cuts and the volume of material processed.

Speed and Efficiency of Operation

Bench shear offers moderate speed suitable for small to medium cutting tasks, with simpler operation and less setup time, making it efficient for precision cuts on thin materials. Guillotine shear excels in speed and efficiency for large-scale cutting, capable of processing thicker and wider metal sheets rapidly with automated features reducing manual effort. Your choice depends on the volume and thickness of materials, where guillotine shear maximizes productivity for heavy-duty jobs while bench shear suits quick, lighter tasks.

Safety Features and Considerations

Bench shears typically incorporate safety features such as blade guards and clamping mechanisms to prevent material kickback and protect fingers during cutting, ensuring operator safety. Guillotine shears often include electronic safety devices like light curtains, emergency stop buttons, and two-hand operation controls to minimize the risk of accidental injury. Understanding these safety considerations helps you choose the appropriate shear tool that aligns with your workplace safety requirements.

Maintenance and Durability

Bench shears require regular blade sharpening and occasional lubrication to maintain optimal cutting performance, with their simpler design resulting in easier and less frequent maintenance. Guillotine shears have more complex mechanical components subject to higher wear, necessitating consistent inspection and timely replacement of parts to ensure durability. The robust construction of guillotine shears typically offers greater longevity under heavy-duty use compared to the lighter-duty bench shear.

Cost Comparison and Investment Value

Bench shears generally have a lower initial cost compared to guillotine shears, making them a more budget-friendly option for small to medium-scale operations. Guillotine shears offer higher precision and faster cutting speeds, which can translate to greater long-term investment value through increased productivity and reduced material waste. Your choice between these tools should weigh immediate budget constraints against potential efficiency gains and operational savings.

Choosing the Right Shear for Your Workshop

Selecting the right shear for your workshop depends on the specific metal cutting needs and material thickness. Bench shears offer precision for lighter gauge metals and smaller jobs with minimal distortion, making them ideal for detailed cuts and frequent use. Guillotine shears excel in handling thicker sheets with straight, clean cuts at higher volumes, providing efficiency for heavy-duty industrial tasks.

Bench shear vs guillotine shear Infographic

libmatt.com

libmatt.com