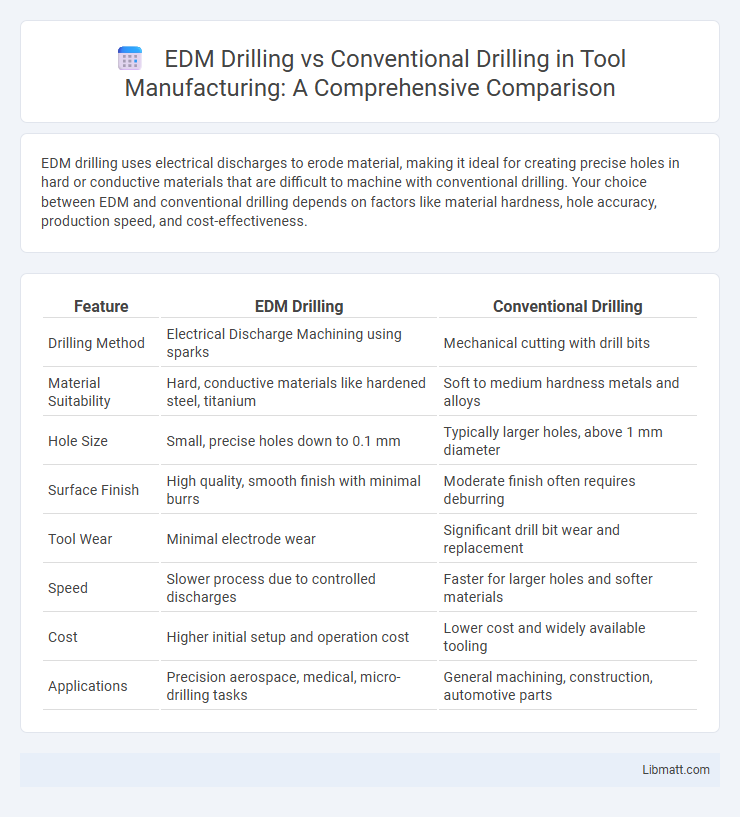

EDM drilling uses electrical discharges to erode material, making it ideal for creating precise holes in hard or conductive materials that are difficult to machine with conventional drilling. Your choice between EDM and conventional drilling depends on factors like material hardness, hole accuracy, production speed, and cost-effectiveness.

Table of Comparison

| Feature | EDM Drilling | Conventional Drilling |

|---|---|---|

| Drilling Method | Electrical Discharge Machining using sparks | Mechanical cutting with drill bits |

| Material Suitability | Hard, conductive materials like hardened steel, titanium | Soft to medium hardness metals and alloys |

| Hole Size | Small, precise holes down to 0.1 mm | Typically larger holes, above 1 mm diameter |

| Surface Finish | High quality, smooth finish with minimal burrs | Moderate finish often requires deburring |

| Tool Wear | Minimal electrode wear | Significant drill bit wear and replacement |

| Speed | Slower process due to controlled discharges | Faster for larger holes and softer materials |

| Cost | Higher initial setup and operation cost | Lower cost and widely available tooling |

| Applications | Precision aerospace, medical, micro-drilling tasks | General machining, construction, automotive parts |

Introduction to EDM Drilling and Conventional Drilling

EDM drilling utilizes electrical discharges to erode material, enabling precision in machining hard metals and intricate geometries unattainable by conventional drilling. Conventional drilling employs mechanical cutting tools to remove material through rotation and pressure, suitable for softer metals and standard hole sizes. EDM drilling offers enhanced accuracy and surface quality, while conventional drilling is faster and more cost-effective for general applications.

How EDM Drilling Works

EDM drilling operates by using electrical discharges between an electrode and the workpiece to erode material precisely without physical contact, making it ideal for hard or brittle materials where conventional drilling would fail. The process involves a controlled spark that vaporizes or melts a small portion of the material with exceptional accuracy and minimal mechanical stress. Your machining projects benefit from EDM drilling's ability to create complex, small-diameter holes with tight tolerances and superior surface finish compared to conventional drilling methods.

How Conventional Drilling Works

Conventional drilling works by mechanically rotating a drill bit to cut through rock or soil, using weight and torque to create a borehole. This process relies on direct contact between the drill bit and the material, often requiring drilling fluids to cool the bit and remove cuttings. Your choice of conventional drilling is ideal for relatively soft to medium-hard formations, where efficient penetration rates and equipment simplicity are essential.

Key Differences Between EDM and Conventional Drilling

EDM drilling utilizes electrical discharges to erode material, enabling precise machining of hard, brittle, or conductive materials without mechanical stress. Conventional drilling relies on a rotating cutting tool to physically remove material, making it suitable for softer materials but prone to tool wear and mechanical deformation. EDM offers superior accuracy, minimal mechanical forces, and the ability to create intricate hole geometries compared to conventional drilling methods.

Materials Suitable for EDM vs. Conventional Drilling

EDM drilling excels in machining hard, electrically conductive materials such as hardened steel, titanium alloys, and exotic superalloys that conventional drilling struggles to penetrate. Conventional drilling is more suitable for softer metals, plastics, and composites where mechanical cutting is efficient and cost-effective. Understanding the material compatibility of EDM versus conventional drilling helps optimize your machining process by selecting the appropriate method for durability and precision.

Precision and Accuracy Comparison

EDM drilling offers superior precision and accuracy compared to conventional drilling due to its ability to create complex holes with minimal tool wear and no mechanical force. Your projects benefit from EDM's capability to achieve tighter tolerances and intricate geometries that are challenging for traditional drills. Conventional drilling may experience tool deflection and vibration, leading to less consistent hole dimensions and surface finishes.

Speed and Efficiency Factors

EDM drilling offers faster penetration rates in hard, conductive materials compared to conventional drilling, which relies on mechanical force and often struggles with tool wear. The electrical discharge process enables precise hole creation with minimal material stress, increasing overall efficiency and reducing machining time. Your choice between EDM and conventional drilling should consider material hardness, hole precision, and production volume to optimize speed and operational efficiency.

Tool Wear and Maintenance Considerations

EDM drilling offers significantly lower tool wear compared to conventional drilling, as it uses electrical discharges rather than mechanical contact, preserving tool integrity. Maintenance for EDM tools primarily involves electrode conditioning and debris removal to maintain precision, while conventional drills require frequent sharpening or replacement due to abrasive wear. The reduced mechanical stress in EDM drilling extends tool lifespan and decreases downtime, enhancing productivity in precise applications.

Cost Implications of Each Method

EDM drilling generally incurs higher initial equipment and operational costs due to its advanced electrical discharge technology and specialized maintenance requirements. Conventional drilling typically offers lower upfront expenses and faster processing times but may lead to increased tool wear and material waste, impacting overall cost-efficiency. In high-precision or hard-to-machine materials, EDM drilling's ability to reduce rework and improve surface finish often results in lower long-term production costs despite its higher initial investment.

Choosing the Right Drilling Technique for Your Application

EDM drilling offers precise and clean holes, ideal for hard materials or intricate designs, while conventional drilling excels in faster, more cost-effective operations on softer metals. Your choice depends on factors like material hardness, hole size, and desired accuracy, with EDM providing superior precision for micro-drilling needs. Selecting the right technique ensures optimal efficiency and quality tailored to your specific application requirements.

EDM drilling vs conventional drilling Infographic

libmatt.com

libmatt.com