A form tool is designed to cut specific shapes or contours in a single pass, creating complex cross-sections, whereas a profile tool follows the outline or edge of a workpiece to produce the desired external or internal contour. Choosing the right tool depends on your machining needs, with form tools ideal for repetitive shapes and profile tools suited for flexible, detailed outlines.

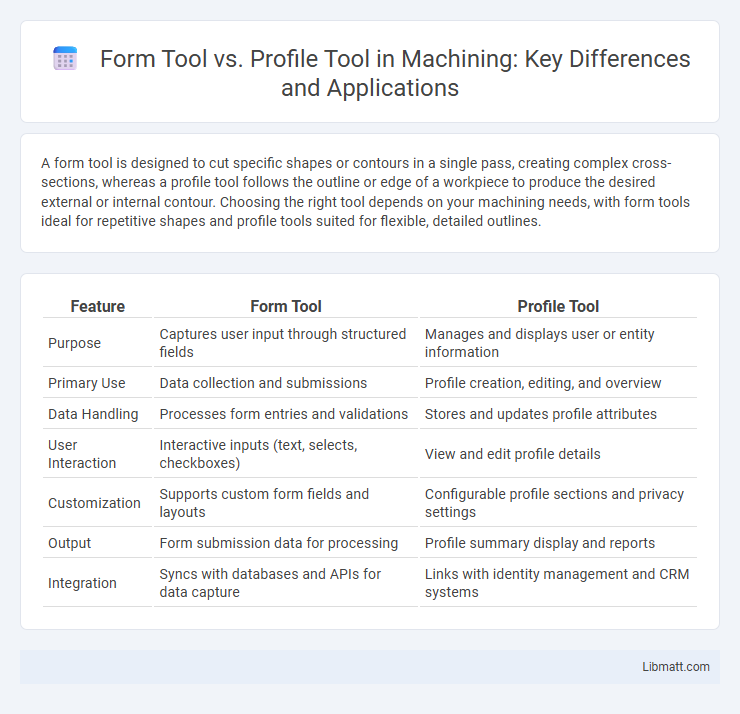

Table of Comparison

| Feature | Form Tool | Profile Tool |

|---|---|---|

| Purpose | Captures user input through structured fields | Manages and displays user or entity information |

| Primary Use | Data collection and submissions | Profile creation, editing, and overview |

| Data Handling | Processes form entries and validations | Stores and updates profile attributes |

| User Interaction | Interactive inputs (text, selects, checkboxes) | View and edit profile details |

| Customization | Supports custom form fields and layouts | Configurable profile sections and privacy settings |

| Output | Form submission data for processing | Profile summary display and reports |

| Integration | Syncs with databases and APIs for data capture | Links with identity management and CRM systems |

Introduction to Form Tools and Profile Tools

Form tools shape or cut materials by following a specific contour or outline, ideal for creating consistent profiles in manufacturing processes. Profile tools, however, are designed to trace a predefined path or surface, enabling precise replication of complex shapes and patterns. Understanding the differences between form tools and profile tools helps optimize Your machining operations for accuracy and efficiency.

Key Differences Between Form Tools and Profile Tools

Form tools create three-dimensional shapes through sweeping or revolving operations, focusing on solid geometry and volume creation. Profile tools primarily generate two-dimensional outlines or paths used as references for cutting, machining, or further processing in CAD/CAM environments. The key difference lies in form tools shaping 3D models, while profile tools define 2D contours essential for manufacturing workflows.

Applications of Form Tools in Manufacturing

Form tools in manufacturing are essential for shaping and cutting materials into specific profiles with precise dimensions and surface finishes, ideal for producing consistent parts in high-volume production runs. These tools are commonly used in applications such as gear cutting, threading, and contour milling where exact replication of complex shapes is required. Your manufacturing process benefits from form tools by enhancing efficiency, reducing manual adjustments, and improving the overall quality of the finished product.

Applications of Profile Tools in Industry

Profile tools are essential in manufacturing industries for precise measurement and inspection of complex geometries on machined parts, ensuring adherence to design specifications and tolerance limits. They are widely used in aerospace for aerofoil shape verification, automotive for engine component profiling, and metalworking for contour quality control. Integration with CNC machines enables real-time monitoring, reducing defects and enhancing production efficiency.

Design Features of Form Tools

Form tools feature curved or rounded cutting edges designed for intricate shaping and sculpting in woodworking or metalworking, enabling precise contour creation. These tools often have specialized geometries tailored to replicate specific shapes, such as molding profiles or decorative patterns. Their design allows for consistent replication of complex curves, improving accuracy and efficiency in detailed crafting projects.

Design Features of Profile Tools

Profile tools feature precisely shaped cutting edges that mirror the desired contour of the workpiece, enabling intricate and accurate milling or shaping operations. These tools are designed with varying profiles such as rounded, angled, or custom shapes to create detailed grooves, edges, or complex surface finishes. Using the right profile tool enhances the precision and aesthetic quality of your manufacturing or woodworking projects.

Material Suitability: Form Tool vs Profile Tool

Form tools excel in machining complex contours with consistent shape, making them ideal for softer materials such as aluminum and plastics where precision profile repetition is needed. Profile tools suit harder materials like steel, offering better wear resistance and the ability to create detailed cuts along a shape's outline. You should select the tool based on your material's hardness and the desired machining accuracy to optimize tool life and surface finish.

Precision and Tolerances: Comparison

Form tools provide higher precision for creating intricate shapes with tight tolerances, making them ideal for detailed and repetitive machining tasks. Profile tools offer versatility for general cutting but may not achieve the same level of exactness in complex geometries. Your choice between these tools directly impacts machining accuracy and product quality in precision-critical applications.

Cost Considerations: Form Tools vs Profile Tools

Form tools generally involve higher upfront costs due to their complex design and customization requirements, making them more expensive to produce and maintain. Profile tools offer a cost-effective alternative with simpler geometry and easier manufacturing processes, reducing both production time and expenses. Choosing between form and profile tools depends largely on budget constraints and the specific application demands in machining or metal forming operations.

Choosing the Right Tool for Your Application

Form tools excel in shaping and cutting materials with complex contours, making them ideal for producing consistent profiles in high-volume applications. Profile tools, on the other hand, specialize in defining precise external shapes and edges, providing greater accuracy for detailed finishes. Your choice depends on whether your focus is on internal shaping or external detail precision in the manufacturing process.

Form tool vs profile tool Infographic

libmatt.com

libmatt.com