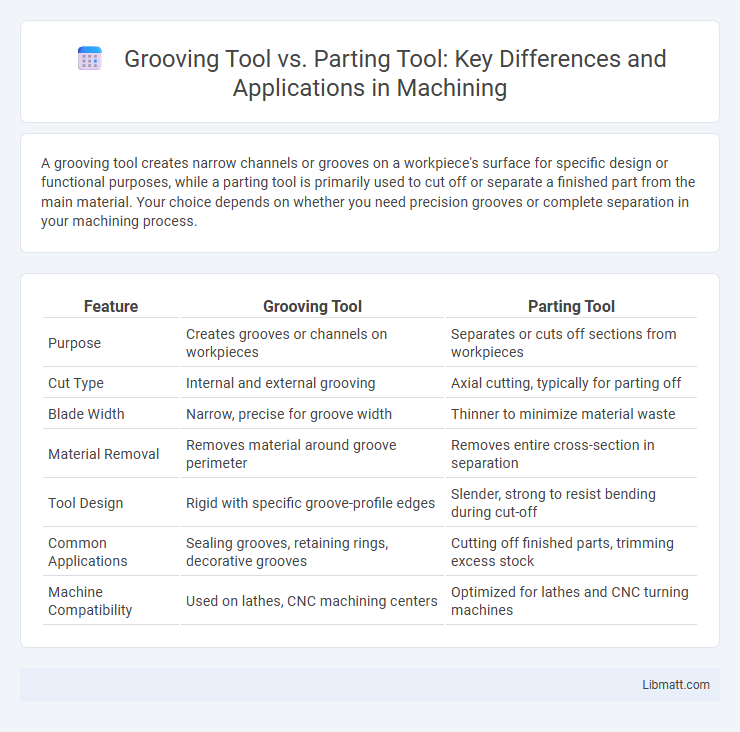

A grooving tool creates narrow channels or grooves on a workpiece's surface for specific design or functional purposes, while a parting tool is primarily used to cut off or separate a finished part from the main material. Your choice depends on whether you need precision grooves or complete separation in your machining process.

Table of Comparison

| Feature | Grooving Tool | Parting Tool |

|---|---|---|

| Purpose | Creates grooves or channels on workpieces | Separates or cuts off sections from workpieces |

| Cut Type | Internal and external grooving | Axial cutting, typically for parting off |

| Blade Width | Narrow, precise for groove width | Thinner to minimize material waste |

| Material Removal | Removes material around groove perimeter | Removes entire cross-section in separation |

| Tool Design | Rigid with specific groove-profile edges | Slender, strong to resist bending during cut-off |

| Common Applications | Sealing grooves, retaining rings, decorative grooves | Cutting off finished parts, trimming excess stock |

| Machine Compatibility | Used on lathes, CNC machining centers | Optimized for lathes and CNC turning machines |

Introduction to Grooving and Parting Tools

Grooving and parting tools are essential in machining for creating precise cuts on workpieces. A grooving tool is designed to cut narrow channels or grooves, enhancing functionality or aesthetics, while a parting tool is used to separate a finished part from the raw material. Your choice between grooving and parting tools depends on the specific machining task and desired outcome.

Understanding Grooving Tools

Grooving tools are designed to create precise grooves or channels on a workpiece, often used in turning operations on lathes. These tools differ from parting tools, which primarily cut off or separate a part from the main workpiece. Grooving tools require careful selection of geometry and material to ensure accuracy, surface finish, and tool life during machining processes.

Overview of Parting Tools

Parting tools are specialized cutting instruments used in machining to separate a finished part from the stock material by cutting a narrow groove. These tools feature a thin, highly rigid blade designed to minimize material wastage and prevent workpiece deformation during the cutting process. Parting tools are commonly employed in turning operations on lathes, where precise separation and clean cuts are critical for efficient production.

Key Differences Between Grooving and Parting Tools

Grooving tools are designed to cut narrow channels or grooves on the surface of a workpiece, focusing on precision and depth control, whereas parting tools are primarily used to cut off or separate a part from the main workpiece. Grooving tools typically have a smaller cutting edge width and are used for internal or external grooves, while parting tools feature a thicker blade aimed at withstanding higher cutting forces during the separation process. The geometry and cutting angles differ significantly, with grooving tools emphasizing fine detail and parting tools prioritizing strength and rigidity for clean cuts through the material.

Applications of Grooving Tools

Grooving tools are primarily used for cutting narrow channels or grooves on the surface of a workpiece, often for retaining rings or seals, while parting tools are designed to cut off sections from the main workpiece. These tools excel in applications requiring precision groove dimensions in shafts, cylinders, and other components, making them essential in automotive, aerospace, and manufacturing industries. Your choice of grooving tool ensures accurate, clean cuts for assembling parts or creating functional surface features.

Uses of Parting Tools

Parting tools are primarily used in turning operations to cut off finished components from the workpiece, ensuring clean separation without damaging the main material. They serve to create grooves, control the width of the cut, and assist in precise dimensional control during metalworking processes. These tools are essential for machining operations requiring accurate part separation and groove formation on lathes.

Tool Design and Geometry Comparison

Grooving tools feature a narrow, precisely angled cutting edge designed to create grooves with specific widths and depths, often incorporating a chip breaker to improve chip evacuation. Parting tools have a thin, straight blade with minimal relief angles to minimize material deformation and allow clean separation of the workpiece. Both tools emphasize rigidity and wear resistance, but grooving tools prioritize complex geometry for precision cuts, while parting tools focus on a straightforward design to ensure efficient cutting and tool life.

Material Compatibility: Grooving vs Parting

Grooving tools excel in machining materials like stainless steel, cast iron, and hardened alloys due to their ability to produce narrow incisions with precision and minimal tool deflection. Parting tools are optimized for softer metals such as aluminum and brass, where they efficiently sever the workpiece without excessive wear. Choosing between grooving and parting tools depends on material hardness and thermal conductivity, as grooving tools often feature tougher carbide inserts for durability in abrasive environments.

Choosing the Right Tool for Your Operation

Selecting the right tool for your machining operation depends largely on the specific task requirements; grooving tools are ideal for creating narrow channels or grooves with precise dimensions, enhancing component functionality. Parting tools excel in cutting off or separating parts from raw material, providing clean, efficient cuts with reduced material wastage. Understanding the distinction between grooving and parting tools ensures optimized tool life, surface finish, and overall machining efficiency.

Maintenance Tips for Grooving and Parting Tools

Regularly inspect the cutting edges of grooving and parting tools for wear or chipping to maintain precision and prolong tool life. Ensure proper lubrication and clean the tool holders to prevent buildup that can affect tool stability and surface finish. You should also follow manufacturer guidelines for sharpening intervals and storage to avoid corrosion and tool damage.

Grooving tool vs parting tool Infographic

libmatt.com

libmatt.com