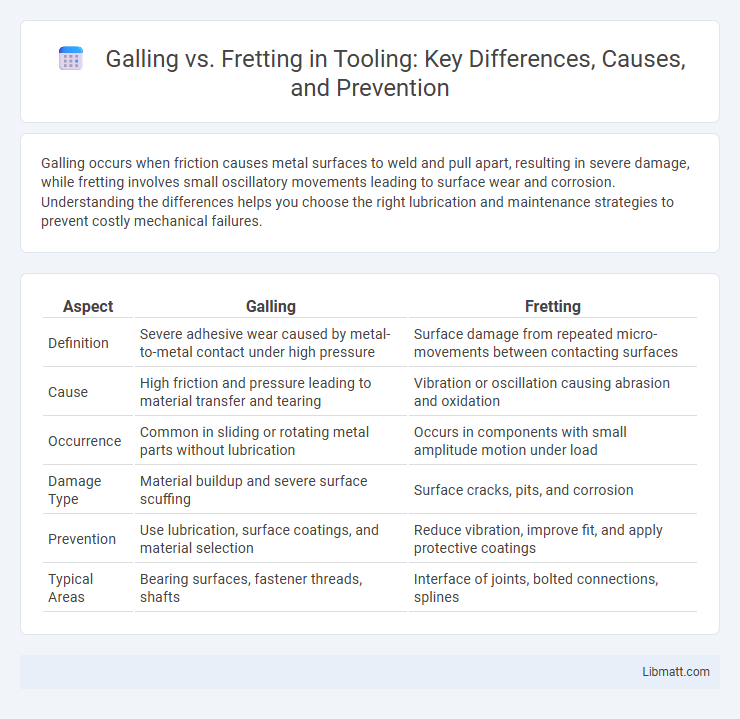

Galling occurs when friction causes metal surfaces to weld and pull apart, resulting in severe damage, while fretting involves small oscillatory movements leading to surface wear and corrosion. Understanding the differences helps you choose the right lubrication and maintenance strategies to prevent costly mechanical failures.

Table of Comparison

| Aspect | Galling | Fretting |

|---|---|---|

| Definition | Severe adhesive wear caused by metal-to-metal contact under high pressure | Surface damage from repeated micro-movements between contacting surfaces |

| Cause | High friction and pressure leading to material transfer and tearing | Vibration or oscillation causing abrasion and oxidation |

| Occurrence | Common in sliding or rotating metal parts without lubrication | Occurs in components with small amplitude motion under load |

| Damage Type | Material buildup and severe surface scuffing | Surface cracks, pits, and corrosion |

| Prevention | Use lubrication, surface coatings, and material selection | Reduce vibration, improve fit, and apply protective coatings |

| Typical Areas | Bearing surfaces, fastener threads, shafts | Interface of joints, bolted connections, splines |

Understanding Galling and Fretting: Key Differences

Galling and fretting are distinct wear mechanisms affecting metal surfaces under stress and motion. Galling involves severe adhesive wear and material transfer due to high contact pressure and sliding, often causing surface tearing and deformation. Fretting, by contrast, results from small oscillatory movements, leading to surface fatigue, micro-cracking, and oxide debris formation that degrades your metal components over time.

What Causes Galling in Metals?

Galling in metals occurs when adhesive wear causes material transfer due to high pressure and friction between contacting surfaces, leading to surface damage and increased roughness. This phenomenon is often triggered by insufficient lubrication, elevated temperature, and surface hardness incompatibility, which cause metal particles to weld and tear during sliding motion. Understanding these causes helps you prevent galling by selecting appropriate materials and applying proper surface treatments or lubricants.

Fretting: Definition and Typical Applications

Fretting is a wear process caused by small oscillatory movements between two contacting surfaces under load, leading to surface damage, material removal, and corrosion. It commonly occurs in applications like turbine blade attachments, electrical contacts, and bolted joints where vibrations or slight motions cause repeated surface contact. Understanding fretting helps protect your mechanical components from fatigue failure and maintain long-term reliability.

Common Materials Susceptible to Galling

Common materials susceptible to galling include stainless steel, aluminum, titanium, and copper alloys, which tend to experience severe adhesive wear under high pressure and sliding contact. These metals exhibit a high tendency for material transfer and surface damage due to their ductile nature and oxide film breakdown. Understanding the susceptibility of these materials helps in selecting appropriate surface treatments or lubricants to mitigate galling in industrial applications.

Conditions Leading to Fretting Damage

Fretting damage occurs under conditions involving small amplitude oscillatory motion between contacting surfaces, often accompanied by high contact stress and limited lubrication. Common environments promoting fretting include vibration exposure, thermal cycling, and relative micromovements in bolted or press-fitted joints. Moisture presence and contaminants can exacerbate fretting by accelerating oxidation and wear at the interface.

Visual Signs: Identifying Galling vs Fretting

Visual signs of galling include severe metal transfer, deep scoring, and raised or torn surface material, often appearing shiny and rough due to adhesive wear. Fretting is characterized by fine red or brown debris, pitting, and surface corrosion caused by micro-motion and oxidation in contact areas. Knowing these differences helps you accurately identify whether damage is due to galling or fretting on mechanical components.

Effects on Mechanical Performance and Reliability

Galling causes severe surface damage and material transfer that leads to increased friction and reduced load-bearing capacity, significantly compromising mechanical performance and component reliability. Fretting results in micro-scale wear and surface fatigue cracks, which initiate corrosion and eventual structural failure, reducing fatigue life and system durability. Both phenomena degrade mechanical integrity but galling typically induces more immediate catastrophic failure, whereas fretting causes gradual deterioration impacting long-term reliability.

Preventive Measures for Galling and Fretting

Preventive measures for galling include applying anti-galling coatings such as PTFE or molybdenum disulfide, using lubricants with high film strength, and selecting materials with dissimilar hardness to reduce adhesive wear. For fretting, maintaining surface cleanliness, employing elastic or polymeric coatings, and designing components to minimize micro-motions help prevent damage. Your equipment's longevity improves significantly by incorporating these targeted strategies to mitigate galling and fretting failures.

Testing Methods for Galling and Fretting Resistance

Testing methods for galling resistance primarily involve standardized tests such as the ASTM G98 galling test, where metal specimens undergo sliding contact under controlled loads to simulate friction-induced material transfer and surface damage. Fretting resistance is assessed using oscillatory motion tests like the ASTM D1876 or fretting fatigue apparatus, which apply small amplitude reciprocating movements between contacting surfaces to evaluate wear and crack initiation. Both testing approaches emphasize measuring wear volume, surface roughness changes, and friction coefficient variations to quantify material performance under distinct mechanical interactions.

Galling vs Fretting: Industry Implications and Case Studies

Galling and fretting are critical wear phenomena impacting industrial components, where galling involves severe adhesive wear causing material transfer and surface damage under high load and sliding conditions, while fretting results from minute oscillatory motion leading to surface fatigue and corrosion. Industries such as aerospace, automotive, and manufacturing report significant case studies demonstrating galling in stainless steel fasteners and fretting in bearing contacts, highlighting the need for precise material selection and lubrication strategies to mitigate failures. Understanding the distinct mechanisms and consequences of galling versus fretting enables engineers to develop targeted maintenance protocols and improve component longevity in high-stress applications.

Galling vs fretting Infographic

libmatt.com

libmatt.com