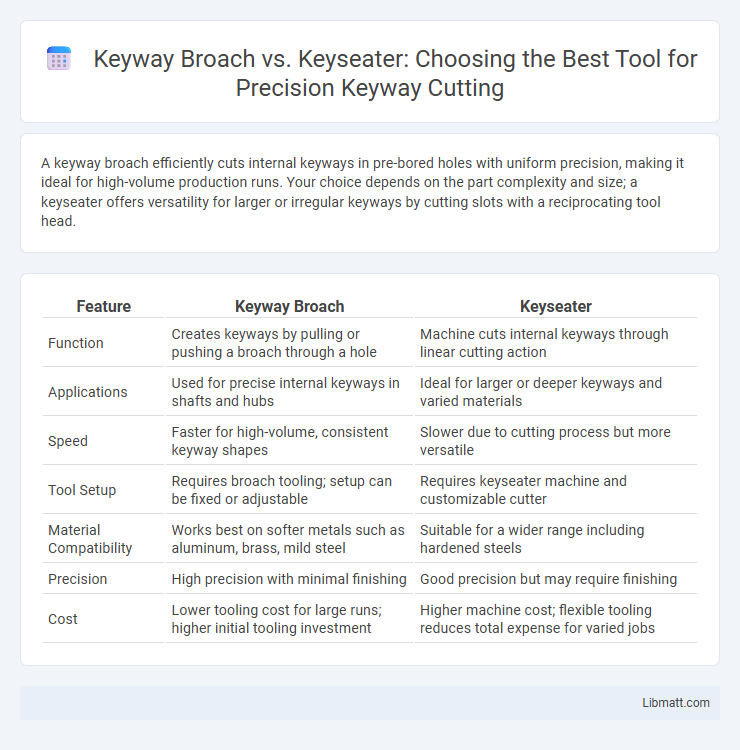

A keyway broach efficiently cuts internal keyways in pre-bored holes with uniform precision, making it ideal for high-volume production runs. Your choice depends on the part complexity and size; a keyseater offers versatility for larger or irregular keyways by cutting slots with a reciprocating tool head.

Table of Comparison

| Feature | Keyway Broach | Keyseater |

|---|---|---|

| Function | Creates keyways by pulling or pushing a broach through a hole | Machine cuts internal keyways through linear cutting action |

| Applications | Used for precise internal keyways in shafts and hubs | Ideal for larger or deeper keyways and varied materials |

| Speed | Faster for high-volume, consistent keyway shapes | Slower due to cutting process but more versatile |

| Tool Setup | Requires broach tooling; setup can be fixed or adjustable | Requires keyseater machine and customizable cutter |

| Material Compatibility | Works best on softer metals such as aluminum, brass, mild steel | Suitable for a wider range including hardened steels |

| Precision | High precision with minimal finishing | Good precision but may require finishing |

| Cost | Lower tooling cost for large runs; higher initial tooling investment | Higher machine cost; flexible tooling reduces total expense for varied jobs |

Introduction to Keyway Broaching and Keyseating

Keyway broaching uses a multi-toothed cutting tool pulled or pushed through a workpiece to create precise internal keyways with high surface finish and dimensional accuracy. Keyseating involves a single-point cutting tool mounted on a reciprocating ram that machines keyways by removing material incrementally, ideal for larger or irregular shapes. Both processes are essential for producing accurate key slots in shafts, gears, and pulleys, but keyway broaching excels in speed and consistency, while keyseating offers versatility for complex geometries.

What is a Keyway Broach?

A keyway broach is a precision cutting tool designed to create internal keyways in mechanical components by removing material with a series of progressively larger teeth. This tool provides high accuracy and smooth finishes for key slots in gears, pulleys, and shafts. You benefit from efficient, repeatable cutting, making the keyway broach ideal for high-volume manufacturing environments.

What is a Keyseater?

A keyseater is a specialized machine tool designed to cut keyways and internal slots with precise control and minimal setup, featuring a vertically reciprocating cutting tool. Unlike a keyway broach, which uses a tapered multi-tooth tool pulled or pushed through a hole in a single pass, the keyseater removes material through incremental vertical strokes, allowing for more flexibility in size and shape. Keyseaters excel in producing deep or wide keyways that are difficult to achieve with broaching, making them ideal for custom or low-volume applications.

Keyway Broaching: Process Overview

Keyway broaching involves using a broach tool with progressively larger teeth to cut keyways in metal workpieces in a single pass, providing high precision and smooth surface finishes. The broaching process is highly efficient for producing internal keyways with consistent dimensions, especially in batch production environments. This method is commonly preferred for keyways in gears, pulleys, and other rotating machinery components requiring accurate key seating.

Keyseating: Process Overview

Keyseating is a machining process used to create internal keyways or slots within a bore, employing a keyseater tool that moves vertically to cut precise grooves. This process offers higher accuracy and flexibility for deep, narrow keyways compared to conventional broaching, making it suitable for complex and custom applications. Your choice between keyway broach and keyseater depends on part geometry, production volume, and required tolerances, with keyseating excelling in versatility and precision.

Comparative Advantages of Keyway Broaching

Keyway broaching offers superior precision and surface finish compared to keyseaters, making it ideal for high-volume production runs where consistent tolerances are critical. The broaching process is faster and more automated, reducing labor costs and minimizing human error compared to the manual setup often required in keyseating. Additionally, keyway broaches produce less vibration and noise, resulting in better tool life and improved overall machine efficiency.

Comparative Advantages of Keyseating

Keyseating machines provide superior precision and flexibility for internal keyway cutting compared to keyway broaches, allowing for the machining of various keyway shapes and sizes with minimal setup time. Unlike broaches, keyseaters can efficiently handle large and irregularly shaped workpieces while maintaining consistent accuracy through controlled cutting action. The ability to perform custom and low-volume keyway production makes keyseating a cost-effective solution in diverse manufacturing environments.

Precision and Tolerances: Broach vs Keyseater

Keyway broaches achieve higher precision and tighter tolerances due to their rigid, guided cutting action, typically maintaining dimensional accuracy within +-0.002 mm. Keyseaters offer greater flexibility for varied keyway sizes but generally have looser tolerances, around +-0.01 mm, because of their less constrained cutting mechanism. The choice between broach and keyseater depends on the required precision, with broaches preferred for high-accuracy, repeatable keyway production.

Application Scenarios: Which to Choose?

Keyway broaches excel in high-volume production of precise internal keyways, making them ideal for small to medium-sized shafts with consistent dimensions. Keyseaters offer versatility for larger, irregular, or custom keyways, often used in repair work or low-volume manufacturing due to their ability to handle varying workpiece sizes. Your choice depends on production scale and keyway complexity, with broaches suited for uniform, repetitive tasks and keyseaters preferred for unique or heavy-duty applications.

Cost Considerations: Broaching vs Keyseating

Broaching typically involves higher upfront tooling costs compared to keyseating, but it offers faster cycle times and lower per-part costs for high-volume production. Keyseaters have lower initial investment and greater flexibility for complex keyway shapes or shorter runs, making them cost-effective for smaller batches. Your choice depends on production volume and complexity, balancing initial expenses with long-term efficiency.

Keyway broach vs keyseater Infographic

libmatt.com

libmatt.com