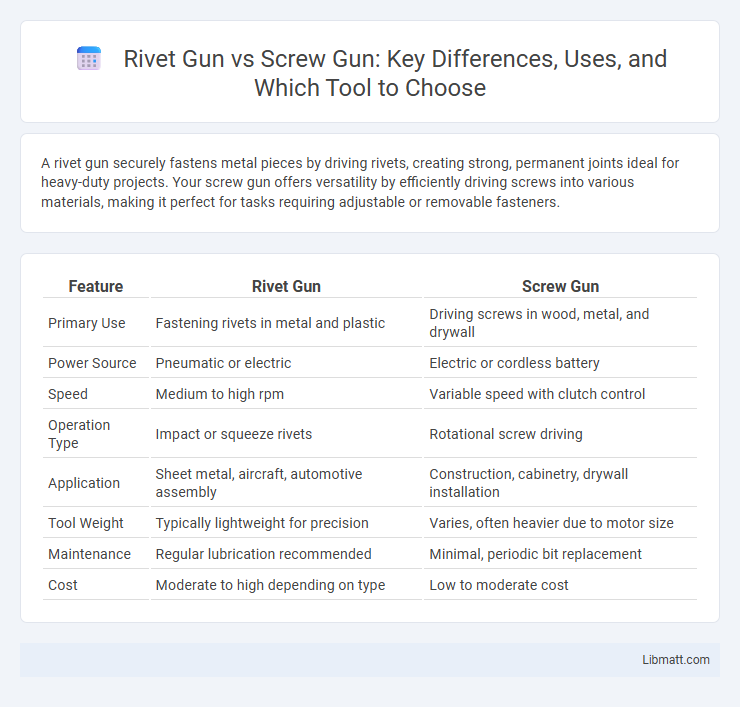

A rivet gun securely fastens metal pieces by driving rivets, creating strong, permanent joints ideal for heavy-duty projects. Your screw gun offers versatility by efficiently driving screws into various materials, making it perfect for tasks requiring adjustable or removable fasteners.

Table of Comparison

| Feature | Rivet Gun | Screw Gun |

|---|---|---|

| Primary Use | Fastening rivets in metal and plastic | Driving screws in wood, metal, and drywall |

| Power Source | Pneumatic or electric | Electric or cordless battery |

| Speed | Medium to high rpm | Variable speed with clutch control |

| Operation Type | Impact or squeeze rivets | Rotational screw driving |

| Application | Sheet metal, aircraft, automotive assembly | Construction, cabinetry, drywall installation |

| Tool Weight | Typically lightweight for precision | Varies, often heavier due to motor size |

| Maintenance | Regular lubrication recommended | Minimal, periodic bit replacement |

| Cost | Moderate to high depending on type | Low to moderate cost |

Introduction to Rivet Guns and Screw Guns

Rivet guns and screw guns serve distinct purposes in fastening applications, with rivet guns designed for installing rivets to join metal sheets securely and screw guns optimized for driving screws quickly into various materials. Rivet guns use pneumatic or electric power to deform rivet tails, creating a strong, permanent joint ideal for metal fabrication and automotive work. Your choice between these tools depends on the project requirements, including the material type and desired fastening strength.

Key Differences Between Rivet Guns and Screw Guns

Rivet guns and screw guns serve distinct functions in fastening applications, with rivet guns designed to install rivets for permanent, vibration-resistant joints, while screw guns drive screws for versatile, removable connections. Rivet guns use pneumatic or hydraulic pressure to deform rivet tails, creating a strong mechanical lock, whereas screw guns provide controlled torque to efficiently fasten screws into various materials. The key differences lie in their fastening methods, types of fasteners used, and suitability for specific construction or manufacturing tasks.

How Rivet Guns Work

Rivet guns operate by driving a rivet through materials, deforming the tail to create a strong, permanent fastening. Using compressed air or electric power, the tool pulls the mandrel or stem, causing the rivet body to expand and tightly clamp the joined surfaces. This process ensures durable, vibration-resistant joints commonly used in metalworking and construction industries.

How Screw Guns Operate

Screw guns operate by using a direct-drive motor that quickly rotates the screwdriver bit to drive screws into various materials with precision and speed. They are designed to maintain consistent torque, allowing for efficient fastening in drywall, wood, and metal applications. Adjustable depth settings enable users to control screw insertion depth, reducing damage and ensuring secure fastening.

Typical Applications for Rivet Guns

Rivet guns are primarily used in aerospace, automotive manufacturing, and metal fabrication where permanent fastenings are required to join metal sheets and components. These tools are essential for assembling aircraft fuselages, trailer frames, and structural steelwork due to their ability to create strong, vibration-resistant joints. Typical applications involve installing blind rivets, blind fasteners, and aluminum or steel rivets in environments demanding durability and corrosion resistance.

Typical Applications for Screw Guns

Screw guns are typically used in construction and woodworking for fastening drywall, subflooring, and decking efficiently. Their design allows for precise screw placement and consistent depth control, making them ideal for repetitive tasks requiring speed and accuracy. You can rely on a screw gun to streamline fastening applications where screws are the primary fastener.

Pros and Cons of Using Rivet Guns

Rivet guns provide strong and permanent fastening ideal for metalwork and construction, offering durability and vibration resistance that screws cannot match. However, their use is limited to specific materials, requiring pre-drilled holes and often specialized rivets, making installation less versatile compared to screw guns. Maintenance involves frequent replacement of rivet heads and can be noisy, which might reduce convenience on delicate or residential projects.

Pros and Cons of Using Screw Guns

Screw guns offer precise control and faster installation for driving screws, making them ideal for drywall and woodworking projects. They reduce hand fatigue due to ergonomic designs and adjustable torque settings but can be limited by their specialization, lacking versatility for tasks requiring heavier-duty fastening. The main drawback includes potential screw stripping if torque is not properly calibrated, which impacts fastening quality and surface integrity.

Choosing Between Rivet Guns and Screw Guns

Choosing between rivet guns and screw guns depends on the specific fastening needs of your project, with rivet guns excelling in creating permanent, vibration-resistant joints ideal for metalwork and automotive applications. Screw guns offer greater versatility for various materials, allowing you to install and remove fasteners efficiently, making them suitable for woodworking and construction tasks. Understanding the durability requirements and material compatibility of your job will help you select the right tool to ensure secure, long-lasting results.

Safety Tips for Using Rivet and Screw Guns

Always wear safety glasses and gloves when using rivet guns or screw guns to protect your eyes and hands from flying debris and accidental slips. Ensure the tools are properly maintained, with no worn or damaged parts, to prevent malfunctions that could cause injuries. Secure your workpiece firmly and keep your fingers clear of the tool's path to maintain control and avoid accidents while operating your rivet or screw gun.

Rivet gun vs screw gun Infographic

libmatt.com

libmatt.com