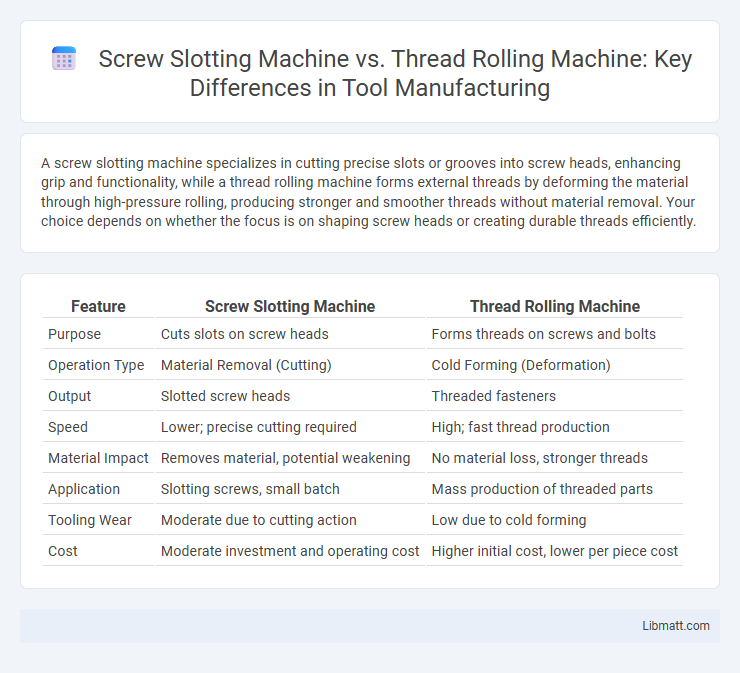

A screw slotting machine specializes in cutting precise slots or grooves into screw heads, enhancing grip and functionality, while a thread rolling machine forms external threads by deforming the material through high-pressure rolling, producing stronger and smoother threads without material removal. Your choice depends on whether the focus is on shaping screw heads or creating durable threads efficiently.

Table of Comparison

| Feature | Screw Slotting Machine | Thread Rolling Machine |

|---|---|---|

| Purpose | Cuts slots on screw heads | Forms threads on screws and bolts |

| Operation Type | Material Removal (Cutting) | Cold Forming (Deformation) |

| Output | Slotted screw heads | Threaded fasteners |

| Speed | Lower; precise cutting required | High; fast thread production |

| Material Impact | Removes material, potential weakening | No material loss, stronger threads |

| Application | Slotting screws, small batch | Mass production of threaded parts |

| Tooling Wear | Moderate due to cutting action | Low due to cold forming |

| Cost | Moderate investment and operating cost | Higher initial cost, lower per piece cost |

Introduction to Screw Slotting and Thread Rolling Machines

Screw slotting machines are designed to create precise slots on screws, enabling secure engagement with screwdrivers or other tools. Thread rolling machines, on the other hand, form screw threads through a cold-forming process that enhances strength and surface finish without material removal. Understanding the specific functions and benefits of these machines helps optimize Your production process for efficient screw manufacturing.

Core Functions of Screw Slotting Machines

Screw slotting machines specialize in creating precise slots on screw heads, enabling effective engagement with screwdrivers or bits by cutting grooves in various materials like metal and plastic. These machines enhance efficiency by providing accurate and consistent slot depths, widths, and positioning essential for functional screw design. Your production process benefits from improved screw quality and compatibility with fastening tools when employing screw slotting machines.

Key Features of Thread Rolling Machines

Thread rolling machines feature high-speed, cold-forming processes that produce continuous, precision threads without removing material, resulting in stronger and more durable screw threads compared to slotting machines. These machines are equipped with hardened steel dies that impress threads onto cylindrical blanks, offering excellent surface finish and enhanced thread accuracy. Your manufacturing efficiency improves with thread rolling due to its faster cycle times and reduced tool wear when contrasted with traditional slotting methods.

Process Differences: Slotting vs Thread Rolling

Screw slotting machines create precise slots on screws by cutting or milling the material, enabling better grip and assembly compatibility. Thread rolling machines form threads through cold forging, displacing material rather than removing it, which results in stronger, smoother threads with improved tensile strength. Understanding these process differences helps you select the appropriate method for your manufacturing needs, optimizing durability and production efficiency.

Material Compatibility and Limitations

Screw slotting machines excel with a wide variety of materials, including soft metals like aluminum and brass, offering precise slot cuts with minimal tool wear, but struggle with extremely hard or brittle materials. Thread rolling machines perform best on ductile metals such as steel and stainless steel, creating strong, precise threads through plastic deformation, but cannot be used on brittle materials or those with coatings that may flake. Material hardness, ductility, and surface finish are critical factors influencing the choice between slotting and thread rolling machines.

Precision and Quality of Output

Screw slotting machines excel in creating precise grooves with consistent depth, ensuring high-quality slots essential for screw heads. Thread rolling machines produce superior threads by deforming material rather than cutting, resulting in stronger, more durable threads with excellent surface finish. Your choice depends on whether precision grooving or robust thread formation is the priority for your manufacturing needs.

Speed and Efficiency Comparison

Screw slotting machines typically operate at moderate speeds, focusing on precision cutting of screw slots with cycle times ranging from 10 to 30 seconds per screw. Thread rolling machines achieve higher efficiency by forming threads through plastic deformation at speeds up to 100 screws per minute, significantly reducing production time. This increased throughput makes thread rolling machines more suitable for high-volume manufacturing environments compared to the slower slotting process.

Operational Costs and Maintenance

Screw slotting machines generally incur higher operational costs due to their complex cutting mechanisms and frequent blade replacements, requiring regular maintenance to ensure precision. Thread rolling machines offer lower maintenance expenses as they use a cold-forming process with minimal tool wear, resulting in increased tool longevity and reduced downtime. You can optimize your manufacturing budget by choosing thread rolling machines for applications prioritizing cost-effective upkeep and consistent production efficiency.

Applications in Various Industries

Screw slotting machines excel in creating precise grooves on screw heads for fastener customization used in automotive and electronics manufacturing. Thread rolling machines are preferred in aerospace, automotive, and construction industries for producing strong, wear-resistant threads on bolts and screws through cold forming. Your choice depends on whether the application requires slotting for fastening tools or robust, high-strength threaded components.

Choosing the Right Machine for Your Needs

Choosing the right machine depends on your production requirements: screw slotting machines specialize in cutting precise slots and grooves in screws, enhancing grip and functionality, while thread rolling machines form screw threads through a cold-forming process that increases strength and surface finish. Consider the volume, material, and specific thread or slot design needed, as thread rolling machines are ideal for high-speed, high-volume production with superior thread integrity, whereas slotting machines offer versatility for custom slot shapes and sizes. Evaluating these factors ensures your investment supports efficient manufacturing and meets your product specifications accurately.

Screw slotting machine vs thread rolling machine Infographic

libmatt.com

libmatt.com