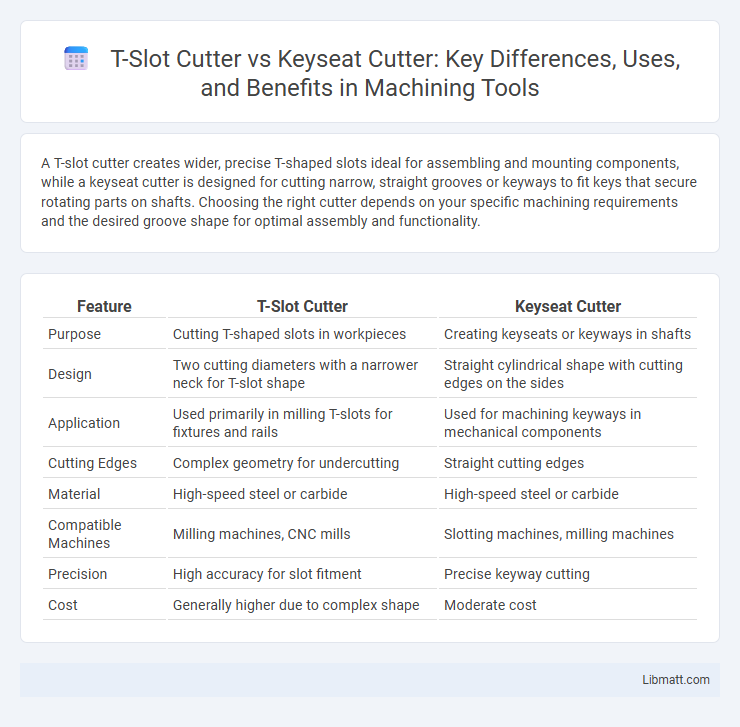

A T-slot cutter creates wider, precise T-shaped slots ideal for assembling and mounting components, while a keyseat cutter is designed for cutting narrow, straight grooves or keyways to fit keys that secure rotating parts on shafts. Choosing the right cutter depends on your specific machining requirements and the desired groove shape for optimal assembly and functionality.

Table of Comparison

| Feature | T-Slot Cutter | Keyseat Cutter |

|---|---|---|

| Purpose | Cutting T-shaped slots in workpieces | Creating keyseats or keyways in shafts |

| Design | Two cutting diameters with a narrower neck for T-slot shape | Straight cylindrical shape with cutting edges on the sides |

| Application | Used primarily in milling T-slots for fixtures and rails | Used for machining keyways in mechanical components |

| Cutting Edges | Complex geometry for undercutting | Straight cutting edges |

| Material | High-speed steel or carbide | High-speed steel or carbide |

| Compatible Machines | Milling machines, CNC mills | Slotting machines, milling machines |

| Precision | High accuracy for slot fitment | Precise keyway cutting |

| Cost | Generally higher due to complex shape | Moderate cost |

Introduction to T-Slot Cutters and Keyseat Cutters

T-slot cutters are specialized milling tools designed to machine precise T-shaped slots for securing components with bolts or fasteners, widely used in metalworking and woodworking applications. Keyseat cutters, also known as Woodruff cutters, create narrow, flat-bottomed grooves for keyways in shafts, ensuring proper alignment and torque transmission in mechanical assemblies. Your choice between T-slot and keyseat cutters depends on the slot shape and application requirements, optimizing machining efficiency and component performance.

Key Differences Between T-Slot and Keyseat Cutters

T-slot cutters feature a T-shaped profile designed to create slots with undercuts for fitting T-head bolts, while keyseat cutters produce straight slots or keyways primarily for securing machine parts. T-slot cutters typically have wider cutting edges and are used for creating structural slots in metal or wood, whereas keyseat cutters offer more precision for locking components with standard key sizes. Your choice depends on whether you need a robust mounting channel or an exact keyway for mechanical assemblies.

T-Slot Cutter: Design and Applications

T-slot cutters feature a narrow cutting head with a wider shank, enabling precise milling of T-shaped slots commonly used for machine tool tables and workholding fixtures. Their design allows for efficient chip evacuation and minimum vibration, improving the quality of grooves for securing clamps and bolts. These cutters are essential in manufacturing processes requiring strong mechanical fastening and alignment in assembled components.

Keyseat Cutter: Design and Common Uses

Keyseat cutters feature a robust, straight-fluted design ideal for creating precise grooves, slots, and keyways in metal and wood. They excel in machining keyseats that require accurate, straight-sided cuts extending into the workpiece, commonly used in mechanical components like shafts and pulleys. Their geometry allows efficient chip removal and minimizes tool deflection, ensuring clean, sharp slots essential for secure key fitting.

Material Compatibility: T-Slot vs Keyseat Cutters

T-slot cutters are designed to work effectively on softer materials like aluminum and plastics, providing clean and precise slots due to their wider cutting edges. Keyseat cutters, with their narrower profile and robust build, excel in cutting harder materials such as stainless steel and hardened alloys by offering stronger chip clearance and reduced cutting forces. Material compatibility dictates the choice between T-slot and keyseat cutters based on the hardness and thickness of the workpiece to ensure optimal cutting performance and tool longevity.

Cutting Efficiency and Performance Comparison

T-slot cutters provide superior cutting efficiency by enabling faster material removal and smoother finishes due to their specialized geometry designed for slotting operations. Keyseat cutters excel in precision and edge quality for narrow keyways but typically operate at lower feed rates, impacting overall throughput. Performance comparison shows T-slot cutters deliver higher productivity in bulk slotting, while keyseat cutters are preferred for detailed, accurate keyseat machining.

Precision and Finish: Which Cutter Delivers Better Results?

T-slot cutters provide superior precision and finish when creating wide slots with flat bottoms, making them ideal for applications requiring clean, straight edges and exact dimensions. Keyseat cutters excel in machining narrow, deep grooves with sharp corners but may produce rougher finishes compared to T-slot cutters. Your choice should consider the desired slot profile and surface quality, with T-slot cutters typically delivering better overall finish and accuracy.

Cost and Tool Longevity Considerations

T-slot cutters generally offer lower initial costs and longer tool longevity due to robust profiles designed for durable slot cutting in softer materials, while keyseat cutters, often more specialized with intricate geometries, tend to have higher costs and shorter lifespan from increased wear in precise keyway machining. The material composition and coating of each cutter significantly influence tool life, with carbide and TiAlN coatings enhancing durability and cost-efficiency in both T-slot and keyseat cutters. Maintenance frequency and cutting conditions, such as feed rate and spindle speed, critically impact the economic performance and longevity of these cutters in industrial applications.

Choosing the Right Cutter for Your Project

Selecting the right cutter for your project hinges on understanding the distinct purposes of T-slot cutters and keyseat cutters. T-slot cutters excel at producing precise, wide slots typically used for fixtures and mounting, while keyseat cutters are designed for narrower, deeper keyways essential in mechanical assemblies. Your choice depends on the slot dimensions and application requirements, ensuring optimal fit and function in your machining operations.

Conclusion: Selecting the Optimal Milling Cutter

Selecting the optimal milling cutter depends on the specific machining requirements of your project. T-slot cutters excel in creating precise slots with wider profiles ideal for assembling components, while keyseat cutters are better suited for cutting narrower, deeper keyways in shafts. Your choice should prioritize slot dimensions, material compatibility, and cutter geometry to achieve efficient and accurate results.

T-slot cutter vs keyseat cutter Infographic

libmatt.com

libmatt.com