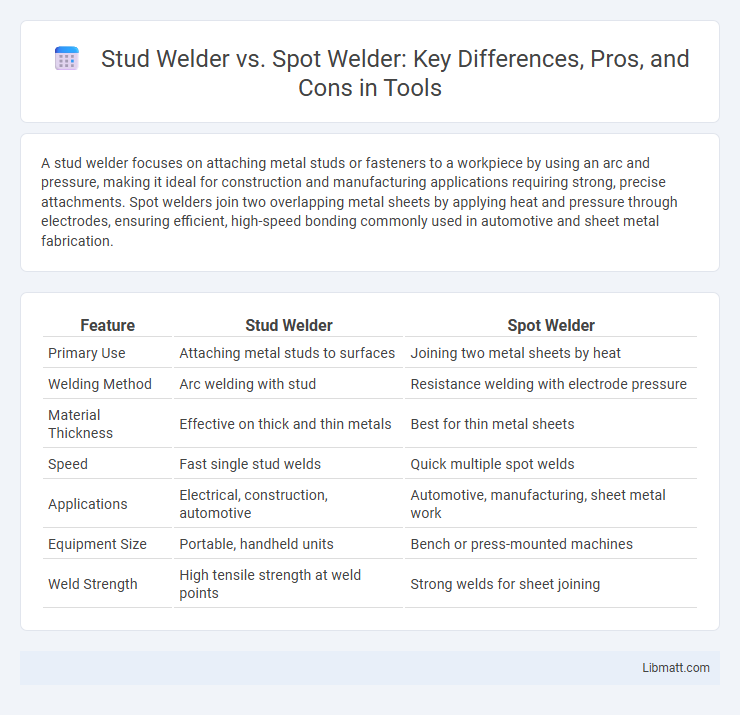

A stud welder focuses on attaching metal studs or fasteners to a workpiece by using an arc and pressure, making it ideal for construction and manufacturing applications requiring strong, precise attachments. Spot welders join two overlapping metal sheets by applying heat and pressure through electrodes, ensuring efficient, high-speed bonding commonly used in automotive and sheet metal fabrication.

Table of Comparison

| Feature | Stud Welder | Spot Welder |

|---|---|---|

| Primary Use | Attaching metal studs to surfaces | Joining two metal sheets by heat |

| Welding Method | Arc welding with stud | Resistance welding with electrode pressure |

| Material Thickness | Effective on thick and thin metals | Best for thin metal sheets |

| Speed | Fast single stud welds | Quick multiple spot welds |

| Applications | Electrical, construction, automotive | Automotive, manufacturing, sheet metal work |

| Equipment Size | Portable, handheld units | Bench or press-mounted machines |

| Weld Strength | High tensile strength at weld points | Strong welds for sheet joining |

Introduction to Stud Welders and Spot Welders

Stud welders create a strong, permanent bond by welding fasteners such as studs or pins directly to a metal surface using a high-current arc. Spot welders join overlapping metal sheets by applying pressure and heat through electrical resistance at specific points, commonly used in automotive manufacturing. Both techniques enable efficient metal joining but are optimized for different applications and materials.

How Stud Welding Works

Stud welding works by using an electric arc to heat a metal stud and the base material simultaneously until both reach melting temperature, creating a strong, fused joint upon cooling. This process involves holding the stud against the workpiece, then triggering the arc which melts the contact area, ensuring a permanent, high-strength bond without the need for additional fasteners or filler materials. Your choice between stud welding and spot welding should consider the specific application requirements, as stud welding excels in attaching studs to metal surfaces efficiently and with superior structural integrity.

How Spot Welding Works

Spot welding joins two or more metal sheets by applying pressure and passing electric current through the electrodes positioned on either side of the workpieces, causing localized heat that melts and fuses the materials at the contact point. The process typically uses copper alloy electrodes that conduct electricity and provide the necessary force to create a weld nugget in milliseconds. Spot welding is widely used in automotive manufacturing and metal fabrication for its speed and efficiency in creating strong, permanent joints without the need for filler material.

Key Differences Between Stud Welding and Spot Welding

Stud welding creates a strong, permanent joint by welding a metal stud directly to a base metal using an arc, ideal for high-strength applications and thicker materials. Spot welding uses electrical resistance to fuse overlapping metal sheets at specific points, commonly employed in automotive and manufacturing industries for thin metals. Your choice depends on the materials, joint strength requirements, and application type, with stud welding offering superior mechanical strength and spot welding providing efficient, rapid production for sheet metals.

Materials Compatible with Stud and Spot Welders

Stud welders are compatible with a variety of metals including steel, stainless steel, aluminum, and copper, making them ideal for fastening thick materials and heavy-duty applications. Spot welders primarily work on thin sheets of steel and stainless steel, commonly used in automotive and manufacturing industries for joining sheet metal components. Understanding the material thickness and metal type is crucial for selecting between stud and spot welding methods to ensure optimal weld strength and quality.

Strength and Durability Comparison

Stud welders create strong, permanent fastenings by fusing a metal stud directly to the base material, ensuring superior strength ideal for heavy-duty applications. Spot welders join overlapping metal sheets through localized heat generated by electrical resistance, providing durable connections primarily suited for thin materials and automotive assembly. Your choice depends on the required load-bearing capacity and material thickness, with stud welding offering enhanced durability for structural components.

Speed and Efficiency: Stud Welding vs Spot Welding

Stud welding offers greater speed and efficiency by creating a strong, permanent bond with a single shot, reducing cycle time compared to spot welding, which relies on multiple weld points. Spot welding requires precise electrode placement and often needs repeated welds for large areas, resulting in longer processing times. Industrial applications benefit from stud welding when high-speed assembly and minimal heat distortion are critical factors.

Common Applications and Industries

Stud welders are commonly used in construction, automotive manufacturing, and shipbuilding for attaching fasteners such as nuts, bolts, and threaded studs directly to metal surfaces, ensuring strong and durable joints. Spot welders find their primary applications in the automotive industry and appliance manufacturing, where they efficiently fuse overlapping metal sheets with high-speed resistance welding. Your choice between these welding tools should align with the specific metal joining requirements typical in fabrication, assembly, or repair tasks within these industries.

Cost Considerations and Equipment Investment

Stud welders typically require a higher initial equipment investment compared to spot welders due to their specialized components and precise control mechanisms. Spot welders tend to have lower upfront costs but may involve higher long-term expenses related to electrode replacement and maintenance. Evaluating total cost of ownership, including operational efficiency and consumable durability, is crucial when choosing between stud welding and spot welding equipment.

Choosing the Right Welding Method for Your Project

Selecting the right welding method depends on project requirements such as material thickness, type, and weld strength. Stud welding provides strong, permanent fastenings ideal for heavy-duty applications, while spot welding suits thinner materials and quick assembly tasks. Evaluating load conditions and production speed helps determine whether stud welding or spot welding best meets your project's specific needs.

Stud welder vs spot welder Infographic

libmatt.com

libmatt.com