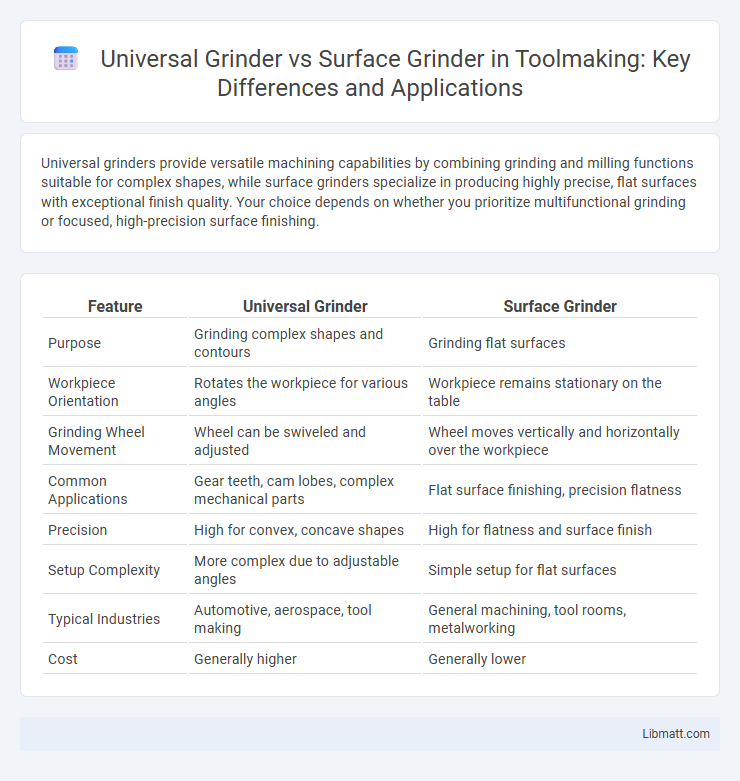

Universal grinders provide versatile machining capabilities by combining grinding and milling functions suitable for complex shapes, while surface grinders specialize in producing highly precise, flat surfaces with exceptional finish quality. Your choice depends on whether you prioritize multifunctional grinding or focused, high-precision surface finishing.

Table of Comparison

| Feature | Universal Grinder | Surface Grinder |

|---|---|---|

| Purpose | Grinding complex shapes and contours | Grinding flat surfaces |

| Workpiece Orientation | Rotates the workpiece for various angles | Workpiece remains stationary on the table |

| Grinding Wheel Movement | Wheel can be swiveled and adjusted | Wheel moves vertically and horizontally over the workpiece |

| Common Applications | Gear teeth, cam lobes, complex mechanical parts | Flat surface finishing, precision flatness |

| Precision | High for convex, concave shapes | High for flatness and surface finish |

| Setup Complexity | More complex due to adjustable angles | Simple setup for flat surfaces |

| Typical Industries | Automotive, aerospace, tool making | General machining, tool rooms, metalworking |

| Cost | Generally higher | Generally lower |

Introduction to Universal and Surface Grinders

Universal grinders feature adjustable work tables allowing multi-angle grinding, making them ideal for complex, irregular shapes and tool manufacturing. Surface grinders specialize in producing smooth flat surfaces with high precision, commonly used in finishing operations for metals and other materials. Both machines enhance manufacturing accuracy but serve distinct roles based on grinding requirements and workpiece geometry.

Key Differences Between Universal and Surface Grinders

Universal grinders offer versatility with adjustable angles and the ability to perform both cylindrical and surface grinding, making them suitable for complex shapes. Surface grinders specialize in producing flat, smooth surfaces with high precision using a fixed grinding wheel and table movement. The primary difference lies in their applications, with universal grinders catering to varied grinding tasks and surface grinders focusing exclusively on planar surfaces.

Overview of Universal Grinder Features

Universal grinders feature adjustable angles and versatile wheel settings that enable both surface and cylindrical grinding in a single machine. These grinders offer rotary tables and multiple axis movements, allowing precise machining of complex shapes and contours on various materials. Your choice of a universal grinder ensures enhanced flexibility for diverse grinding applications compared to the fixed, single-purpose surface grinder.

Overview of Surface Grinder Features

Surface grinders feature a rotating abrasive wheel designed to produce flat, smooth surfaces on metal workpieces with high precision and consistent finish quality. These machines typically include a magnetic chuck for securely holding ferrous materials and allow for fine adjustments in wheel positioning to achieve exact surface tolerances. When considering your machining needs, understanding the surface grinder's emphasis on flat surface finishing versus the multifunctionality of a universal grinder is crucial.

Typical Applications of Universal Grinders

Universal grinders excel in complex machining tasks such as cylindrical, surface, and internal grinding, commonly used in manufacturing automotive components, aerospace parts, and precision tools. Their versatility allows for grinding of tapered, straight, and contoured surfaces, making them ideal for industries requiring diverse and intricate finishes. These machines are particularly suited for production environments where multiple grinding operations must be performed without changing setups.

Typical Uses for Surface Grinders

Surface grinders are typically used for precision finishing on flat surfaces, ensuring high accuracy and smoothness on metal or non-metal workpieces. They excel in preparing parts for assembly by creating consistent, flat surfaces with tight tolerances in manufacturing and fabrication industries. Your projects benefit from surface grinders when requiring detailed surface correction, polishing, or parallel surface generation.

Advantages of Universal Grinders

Universal grinders offer exceptional versatility by accommodating various shapes and sizes of workpieces, allowing you to perform both cylindrical and surface grinding with a single machine. Their adjustable table and head facilitate complex angular and profile grinding, increasing precision and efficiency in machining diverse components. These advantages make universal grinders ideal for workshops requiring flexible operations without investing in multiple specialized machines.

Advantages of Surface Grinders

Surface grinders offer precise flat surface finishing with high accuracy and smoothness, ideal for creating perfectly parallel surfaces on metal, glass, or ceramic workpieces. Their capability to produce consistent surface finishes at tighter tolerances enhances your manufacturing quality, making them suitable for tool and die making or precision engineering. Compared to universal grinders, surface grinders typically provide simpler operation and higher efficiency for flat grinding tasks.

Factors to Consider When Choosing Between Universal and Surface Grinder

Choosing between a universal grinder and a surface grinder involves evaluating factors such as the type of workpiece and grinding requirements; universal grinders offer versatility for complex shapes and various grinding angles, while surface grinders prioritize precision on flat surfaces. Consider the desired accuracy and surface finish, as surface grinders provide superior flatness and smoother finishes compared to universal grinders. Machine size, cost, and the range of grinding operations also impact the decision, with universal grinders typically supporting multiple functions at a higher investment.

Conclusion: Which Grinder Is Right for Your Needs?

Universal grinders offer versatile grinding capabilities with adjustable angles and multiple axes, ideal for complex, precise workpieces requiring varied shapes and contours. Surface grinders excel in producing flat, smooth finishes on metal or other materials, perfect for high-precision surface planarization with consistent dimensions. Choosing the right grinder depends on project requirements: opt for a universal grinder for intricate, multi-angle tasks and a surface grinder for uniform, flat surface finishes.

Universal grinder vs surface grinder Infographic

libmatt.com

libmatt.com