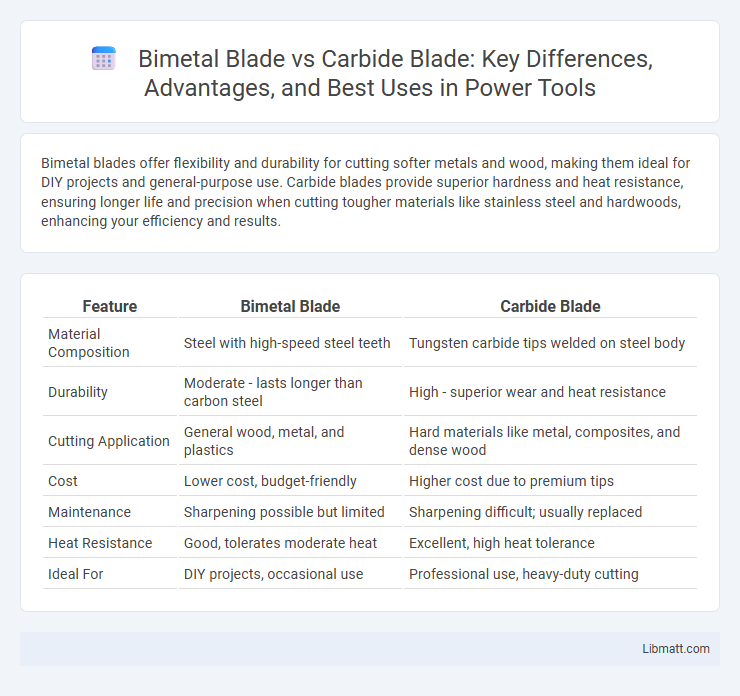

Bimetal blades offer flexibility and durability for cutting softer metals and wood, making them ideal for DIY projects and general-purpose use. Carbide blades provide superior hardness and heat resistance, ensuring longer life and precision when cutting tougher materials like stainless steel and hardwoods, enhancing your efficiency and results.

Table of Comparison

| Feature | Bimetal Blade | Carbide Blade |

|---|---|---|

| Material Composition | Steel with high-speed steel teeth | Tungsten carbide tips welded on steel body |

| Durability | Moderate - lasts longer than carbon steel | High - superior wear and heat resistance |

| Cutting Application | General wood, metal, and plastics | Hard materials like metal, composites, and dense wood |

| Cost | Lower cost, budget-friendly | Higher cost due to premium tips |

| Maintenance | Sharpening possible but limited | Sharpening difficult; usually replaced |

| Heat Resistance | Good, tolerates moderate heat | Excellent, high heat tolerance |

| Ideal For | DIY projects, occasional use | Professional use, heavy-duty cutting |

Introduction to Bimetal and Carbide Blades

Bimetal blades combine high-speed steel teeth welded to a flexible alloy steel backing, offering durability and resistance to impact for cutting various metals. Carbide blades feature tungsten carbide tips brazed onto a steel body, providing superior hardness and heat resistance for cutting tougher materials with precision. Choosing between bimetal and carbide blades depends on cutting speed, material hardness, and blade longevity requirements.

Material Composition of Bimetal vs Carbide Blades

Bimetal blades combine a high-speed steel cutting edge with a flexible, durable steel backing, offering excellent resistance to impact and heat. Carbide blades feature cutting edges made from tungsten carbide, a composite material renowned for its extreme hardness and wear resistance, significantly outperforming traditional steel in longevity. The material composition difference results in bimetal blades being more flexible and cost-effective, while carbide blades deliver superior durability and cutting precision for demanding applications.

Cutting Performance and Efficiency Comparison

Bimetal blades offer a balance of flexibility and durability, providing efficient cutting performance for softer metals and general-purpose use with reduced risk of blade breakage. Carbide blades excel in hardness and wear resistance, delivering superior cutting precision and longevity when working with tougher materials such as stainless steel and hardened alloys. Your choice between bimetal and carbide blades should align with the specific material hardness and cutting speed requirements to maximize efficiency and blade lifespan.

Durability and Lifespan Differences

Bimetal blades feature a flexible steel body with high-speed steel teeth, providing excellent toughness and resistance to impact, making them durable for general-purpose cutting tasks. Carbide blades, composed of tungsten carbide tips bonded to a steel body, offer superior hardness and wear resistance, resulting in a significantly longer lifespan, especially when cutting abrasive or hard materials. Your choice should consider that while carbide blades last longer and maintain sharpness better, bimetal blades excel in flexibility and toughness, ideal for diverse cutting conditions.

Applications: Best Uses for Bimetal Blades

Bimetal blades excel in cutting applications involving wood, plastic, and soft metals due to their flexibility and resistance to impact. These blades are ideal for tasks requiring durability combined with precise, clean cuts in materials such as plywood, MDF, and aluminum. Their ability to handle intermittent cuts without excessive wear makes them suitable for construction, woodworking, and light metal fabrication projects.

Applications: Best Uses for Carbide Blades

Carbide blades excel in cutting hard materials such as stainless steel, cast iron, non-ferrous metals, and high-density plastics, making them ideal for industrial applications requiring precision and durability. These blades maintain sharpness longer under high-temperature conditions and continuous use, providing superior performance in woodworking, metal fabrication, and composite material cutting. Their wear resistance and versatility make carbide blades the preferred choice for heavy-duty machining and high-speed operations.

Cost Analysis: Bimetal vs Carbide Blades

Bimetal blades generally offer a lower upfront cost compared to carbide blades, making them cost-effective for budget-conscious projects and frequent blade replacements. Carbide blades, while more expensive initially, provide superior durability and longer lifespan, reducing the need for frequent replacements and lowering long-term operational costs. The choice between bimetal and carbide blades depends on balancing immediate budget constraints with anticipated usage and maintenance expenses.

Maintenance and Sharpening Requirements

Bimetal blades require more frequent sharpening due to their thinner high-speed steel edge, which dulls faster but can be easily resharpened with standard sharpening tools. Carbide blades maintain their sharpness significantly longer thanks to their hard carbide tips but demand specialized grinding equipment for sharpening, making maintenance less frequent yet more complex. Choosing between the two depends on balancing ease of routine maintenance against the longevity and expense of professional sharpening.

Safety Considerations for Each Blade Type

Bimetal blades, featuring a flexible steel body with tungsten carbide teeth, offer reduced risk of blade shattering, enhancing operator safety during cutting tasks. Carbide blades, while extremely durable and heat-resistant, require careful handling due to their brittle nature, increasing the potential for fracture and injury if misused. Proper maintenance, correct blade selection, and protective equipment are crucial to mitigate safety hazards associated with both blade types.

Choosing the Right Blade for Your Project

Selecting between a bimetal blade and a carbide blade depends on the material and precision required for your project. Bimetal blades, known for durability and flexibility, excel in cutting wood, metal, and plastics with moderate wear resistance. Carbide blades offer superior hardness and heat resistance, making them ideal for heavy-duty applications and materials like hardened steel or abrasive composites where longevity and cutting accuracy are critical.

Bimetal blade vs carbide blade Infographic

libmatt.com

libmatt.com