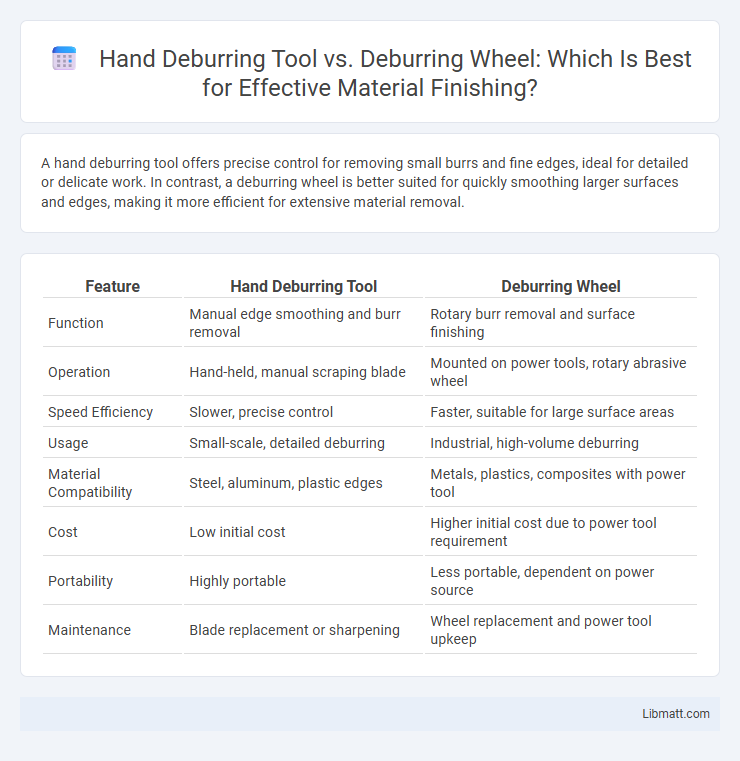

A hand deburring tool offers precise control for removing small burrs and fine edges, ideal for detailed or delicate work. In contrast, a deburring wheel is better suited for quickly smoothing larger surfaces and edges, making it more efficient for extensive material removal.

Table of Comparison

| Feature | Hand Deburring Tool | Deburring Wheel |

|---|---|---|

| Function | Manual edge smoothing and burr removal | Rotary burr removal and surface finishing |

| Operation | Hand-held, manual scraping blade | Mounted on power tools, rotary abrasive wheel |

| Speed Efficiency | Slower, precise control | Faster, suitable for large surface areas |

| Usage | Small-scale, detailed deburring | Industrial, high-volume deburring |

| Material Compatibility | Steel, aluminum, plastic edges | Metals, plastics, composites with power tool |

| Cost | Low initial cost | Higher initial cost due to power tool requirement |

| Portability | Highly portable | Less portable, dependent on power source |

| Maintenance | Blade replacement or sharpening | Wheel replacement and power tool upkeep |

Introduction to Deburring Methods

Hand deburring tools provide precise control for removing burrs on small or intricate parts, making them ideal for detailed finishing work. Deburring wheels offer faster material removal and are suited for larger surfaces or heavy-duty applications where efficiency is prioritized. Both methods are essential in manufacturing and metalworking to ensure smooth edges and improve part quality.

What is a Hand Deburring Tool?

A hand deburring tool is a manual device designed specifically for removing burrs and sharp edges from metal, plastic, or other materials. It typically features replaceable blades or tips that allow precise control and access to tight spots, ensuring smooth and safe finishes. You can rely on a hand deburring tool for detailed deburring tasks where accuracy and ease of handling are essential.

What is a Deburring Wheel?

A deburring wheel is a rotary abrasive tool designed to remove rough edges, burrs, and excess material from metal, plastic, or wood surfaces. Compared to a hand deburring tool, a deburring wheel offers faster material removal and smoother finishes on larger or curved surfaces. You can use a deburring wheel with power tools like grinders for efficient, consistent deburring in industrial and workshop settings.

Key Differences Between Hand Deburring Tools and Deburring Wheels

Hand deburring tools provide precise control for removing burrs from small or intricate edges, making them ideal for detailed work on metal, plastic, and wood surfaces. Deburring wheels, typically abrasive and mounted on power tools, offer faster material removal and are suited for larger surface areas where efficiency is key. The main differences lie in their application scope: hand deburring tools excel in accuracy and finesse, while deburring wheels prioritize speed and bulk removal on broader surfaces.

Material Compatibility and Application Range

Hand deburring tools offer precise control and are ideal for small, detailed tasks on metals like aluminum, steel, and brass, making them suitable for intricate applications and delicate materials. Deburring wheels excel in speed and efficiency when working on larger surfaces or tougher materials such as stainless steel and cast iron, providing a broader application range for heavy-duty deburring. Your choice depends on the material you're working with and the scope of your project, ensuring optimal results with the right tool.

Efficiency and Speed Comparison

Hand deburring tools offer precise control for small, detailed tasks but generally operate slower than deburring wheels, which excel in quickly removing material from larger surfaces. Deburring wheels, often attached to power tools, significantly increase efficiency by covering broader areas faster, making them ideal for high-volume applications. The choice depends on project size and required precision, with wheels favored for speed and hand tools preferred for intricate deburring.

Surface Finish Quality: Hand Tools vs. Wheels

Hand deburring tools deliver precise control for fine surface finish quality, ideal for delicate or intricate work requiring minimal material removal. Deburring wheels excel in efficiently smoothing larger areas and removing burrs quickly but may sacrifice some precision compared to hand tools. Your choice depends on balancing surface finish quality with the speed and scale of the deburring task.

Cost Considerations for Each Method

Hand deburring tools typically have lower upfront costs, making them ideal for small-scale or occasional deburring tasks, while deburring wheels involve a higher initial investment due to the need for machinery and replacement parts. Maintenance costs for hand tools are minimal, but they can be time-consuming and less efficient for large projects. Your choice depends on balancing initial expenses against long-term productivity and volume of work.

Safety and Ease of Use

Hand deburring tools offer precise control with minimal risk of injury due to their ergonomic design and manual operation, making them safer for detailed work in tight spaces. Deburring wheels, while efficient for larger surface areas, pose higher safety risks from spinning blades and require proper protective gear and experience to prevent accidents. Ease of use favors hand deburring tools for beginners and intricate tasks, whereas deburring wheels demand skill and caution but provide faster results on extensive edges.

Choosing the Right Deburring Solution for Your Needs

Choosing the right deburring solution depends on the scale and precision of your project, with hand deburring tools offering precise control for delicate edges and deburring wheels providing efficient material removal on larger surfaces. Hand deburring tools excel in detailed tasks and tight spaces, making them ideal for fine metalwork or plastic components. Deburring wheels, compatible with power tools, enhance productivity for bulk processing, so your choice should align with the complexity and volume of your deburring requirements.

Hand deburring tool vs deburring wheel Infographic

libmatt.com

libmatt.com