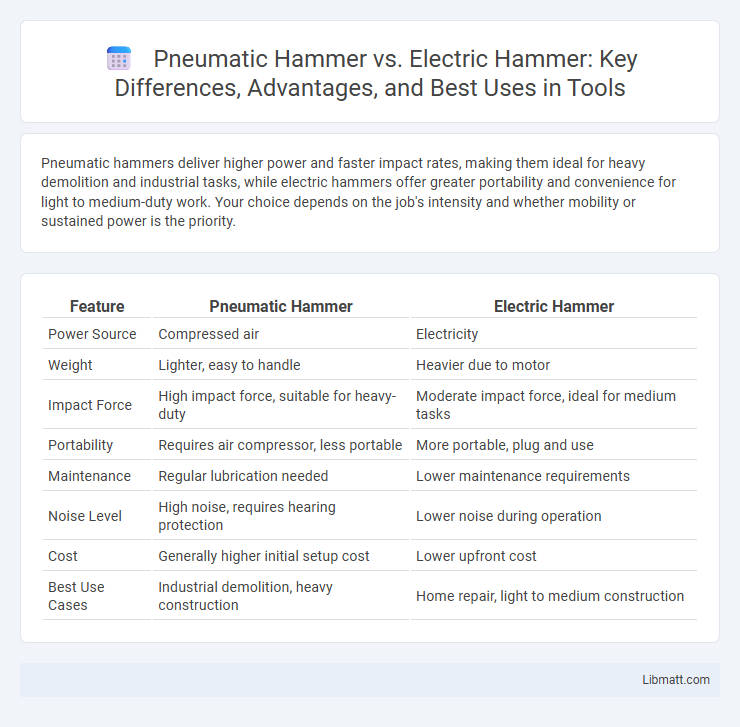

Pneumatic hammers deliver higher power and faster impact rates, making them ideal for heavy demolition and industrial tasks, while electric hammers offer greater portability and convenience for light to medium-duty work. Your choice depends on the job's intensity and whether mobility or sustained power is the priority.

Table of Comparison

| Feature | Pneumatic Hammer | Electric Hammer |

|---|---|---|

| Power Source | Compressed air | Electricity |

| Weight | Lighter, easy to handle | Heavier due to motor |

| Impact Force | High impact force, suitable for heavy-duty | Moderate impact force, ideal for medium tasks |

| Portability | Requires air compressor, less portable | More portable, plug and use |

| Maintenance | Regular lubrication needed | Lower maintenance requirements |

| Noise Level | High noise, requires hearing protection | Lower noise during operation |

| Cost | Generally higher initial setup cost | Lower upfront cost |

| Best Use Cases | Industrial demolition, heavy construction | Home repair, light to medium construction |

Introduction to Pneumatic and Electric Hammers

Pneumatic hammers use compressed air to deliver powerful, rapid strikes, making them ideal for heavy-duty demolition and construction tasks. Electric hammers rely on an electric motor to generate impact force, offering convenience and ease of use without needing an air compressor. Your choice depends on the specific job requirements, power availability, and portability needs.

How Pneumatic Hammers Work

Pneumatic hammers operate using compressed air to generate rapid, powerful strikes through a piston mechanism, enabling efficient demolition and heavy-duty driving tasks. The compressed air flows into the hammer's cylinder, pushing the piston back and forth to deliver consistent blows with minimal effort from the user. Your choice between pneumatic and electric hammers may depend on the need for sustained power and durability typically offered by pneumatic models in industrial settings.

How Electric Hammers Operate

Electric hammers operate using an electric motor that drives a piston or hammer mechanism to deliver rapid, repetitive blows to a surface, providing precise control and ease of use. Their power source is typically standard electrical outlets or rechargeable batteries, making them highly portable and suitable for various construction and demolition tasks. Your choice between pneumatic and electric hammers depends on the need for mobility, power consistency, and the availability of an air compressor.

Power and Performance Comparison

Pneumatic hammers typically deliver higher impact energy measured in joules per blow, making them ideal for heavy-duty demolition and industrial applications requiring sustained power. Electric hammers offer consistent torque and adjustable speed settings, providing improved control and efficiency for medium to light tasks. Your choice depends on balancing raw power needs against operational convenience and precision.

Efficiency in Different Work Environments

Pneumatic hammers deliver higher power and are more efficient in heavy-duty construction and industrial demolition where continuous, high-impact force is required. Electric hammers excel in lighter to medium tasks, offering greater portability, ease of use, and reduced noise, making them ideal for residential renovation and indoor projects. Selecting between pneumatic and electric hammers depends on the specific work environment demands regarding power, mobility, and noise restrictions.

Durability and Maintenance Requirements

Pneumatic hammers offer superior durability due to fewer moving electrical parts and resistance to overheating, making them ideal for heavy-duty and continuous use. Electric hammers require more frequent maintenance to address motor wear and electrical component issues, which can lead to shorter service life under intense conditions. Your choice depends on balancing long-term durability needs with maintenance capabilities for specific job demands.

Cost Analysis: Initial Investment and Long-Term Expenses

Pneumatic hammers generally require a higher initial investment due to the cost of air compressors and maintenance equipment, while electric hammers tend to have a lower upfront price and simpler setup. Long-term expenses for pneumatic hammers can include frequent compressor servicing and air leaks, increasing operational costs, whereas electric hammers often incur lower energy consumption and maintenance fees over time. Evaluating your specific project needs and usage frequency will help determine which tool offers better cost efficiency for your investment.

Safety Considerations for Both Types

Pneumatic hammers pose risks such as high noise levels and the need for proper air pressure regulation, requiring operators to use hearing protection and secure air hoses to prevent accidents. Electric hammers demand attention to electrical safety, including insulation checks and avoiding wet conditions to reduce the risk of electric shock. Both types necessitate the use of personal protective equipment like gloves and safety goggles to mitigate potential injuries from flying debris and vibrations.

Best Applications for Pneumatic vs Electric Hammers

Pneumatic hammers excel in heavy-duty demolition, construction, and industrial applications where high impact energy and continuous operation are required, such as breaking concrete or driving large nails or spikes. Electric hammers are ideal for lighter to medium tasks including small-scale demolition, drilling, and chiseling in residential or indoor environments due to their portability, quieter operation, and easier maintenance. Choosing between pneumatic and electric hammers depends on the specific job demands, with pneumatic tools favored for power-intensive projects and electric models preferred for convenience and precision.

Choosing the Right Hammer for Your Project

Selecting between a pneumatic hammer and an electric hammer depends on the intensity and duration of your project. Pneumatic hammers offer greater power and durability for heavy-duty tasks like demolition or industrial use, while electric hammers provide convenience and portability suitable for light to medium DIY work. Your choice should consider the hammer's impact force, weight, and power source to match the specific requirements of your project efficiently.

Pneumatic hammer vs electric hammer Infographic

libmatt.com

libmatt.com