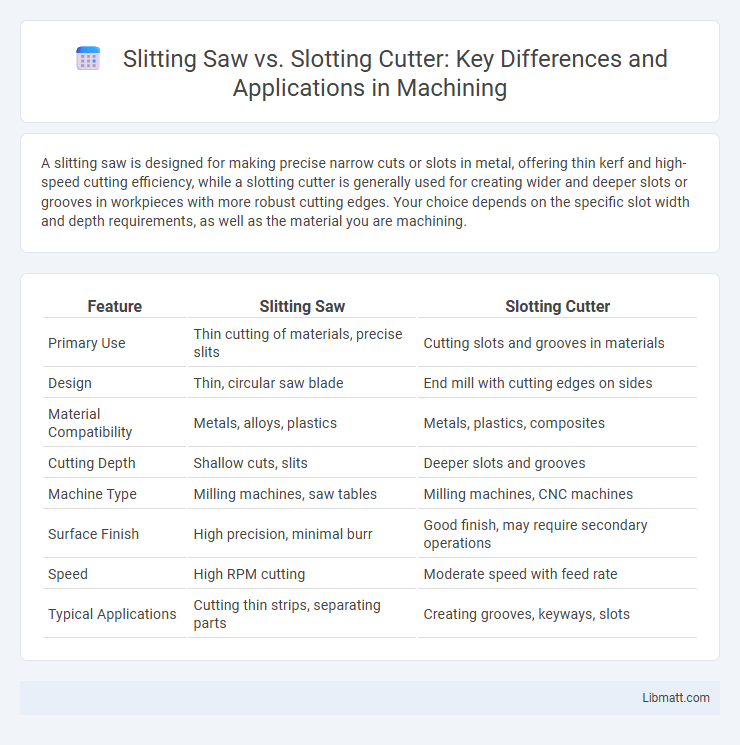

A slitting saw is designed for making precise narrow cuts or slots in metal, offering thin kerf and high-speed cutting efficiency, while a slotting cutter is generally used for creating wider and deeper slots or grooves in workpieces with more robust cutting edges. Your choice depends on the specific slot width and depth requirements, as well as the material you are machining.

Table of Comparison

| Feature | Slitting Saw | Slotting Cutter |

|---|---|---|

| Primary Use | Thin cutting of materials, precise slits | Cutting slots and grooves in materials |

| Design | Thin, circular saw blade | End mill with cutting edges on sides |

| Material Compatibility | Metals, alloys, plastics | Metals, plastics, composites |

| Cutting Depth | Shallow cuts, slits | Deeper slots and grooves |

| Machine Type | Milling machines, saw tables | Milling machines, CNC machines |

| Surface Finish | High precision, minimal burr | Good finish, may require secondary operations |

| Speed | High RPM cutting | Moderate speed with feed rate |

| Typical Applications | Cutting thin strips, separating parts | Creating grooves, keyways, slots |

Introduction to Slitting Saws and Slotting Cutters

Slitting saws are thin, circular cutting tools designed primarily for making narrow, precise cuts or slots in metal or other materials, often used in milling machines. Slotting cutters, on the other hand, are cylindrical tools with multiple cutting edges on the periphery and face, used to create slots, grooves, or keyways with greater depth and width control. Both tools play critical roles in machining processes but differ in their geometry, application scope, and cutting efficiency.

Key Differences Between Slitting Saws and Slotting Cutters

Slitting saws are designed primarily for thin, precise cuts and are typically used in metalworking to create narrow slots or cut off pieces with minimal material removal. Slotting cutters, on the other hand, are thicker and intended for creating wider, deeper slots or keyways in various materials, offering greater durability and stability during heavier cuts. Your choice between the two depends on the specific machining requirements, such as cut width, depth, and material hardness.

Design and Construction of Slitting Saws

Slitting saws feature a thin, circular blade with multiple teeth designed for precise cutting of narrow slots and grooves, enabling high-speed machining with minimal material waste. Their construction typically includes hardened steel or carbide tips for durability and efficient heat dissipation during high RPM operations. Your choice between a slitting saw and a slotting cutter depends on the required slot width, cutting speed, and material hardness.

Design and Construction of Slotting Cutters

Slotting cutters feature a robust design with multiple teeth arranged along the cutter's circumference, enabling efficient material removal in narrow slots. Their construction typically incorporates high-speed steel (HSS) or carbide tips to withstand high cutting forces and ensure durability during heavy-duty machining. Compared to slitting saws, slotting cutters have a thicker body and reinforced tooth geometry to enhance stability and reduce vibration in deep slotting operations.

Common Applications of Slitting Saws

Slitting saws are primarily used for precision cutting in metalworking, including creating narrow slots, cutting thin materials, and parting off stock with minimal kerf width. They excel in applications requiring fine, accurate cuts such as gear cutting, keyway slotting, and trimming castings or forgings. Slitting saws are favored in industries like aerospace and automotive for their ability to produce clean edges on hard materials.

Typical Uses for Slotting Cutters

Slotting cutters are primarily used for creating precise grooves, slots, and keyways in metalworking and machining applications, offering excellent accuracy and surface finish. These cutters excel in cutting narrow slots that require fine detail, such as in mechanical parts, gear manufacturing, and mold-making. Your project benefits from their ability to handle various materials with minimal burr formation, providing clean and consistent cuts.

Advantages of Using Slitting Saws

Slitting saws offer superior precision and cleaner cuts compared to slotting cutters, making them ideal for thin or delicate material cutting tasks. Their thin blade design reduces material waste and heat generation, enhancing tool life and workpiece quality. Slitting saws also provide faster cutting speeds and smoother finishes, which increase overall machining efficiency and accuracy.

Benefits of Slotting Cutters in Machining

Slotting cutters offer precise, efficient material removal for creating narrow slots or grooves, essential in intricate machining tasks. Their design provides superior chip clearance and reduced cutting forces compared to slitting saws, enhancing tool life and surface finish quality. Using slotting cutters can improve your machining accuracy and overall productivity in complex metalworking applications.

Choosing the Right Tool: Factors to Consider

When choosing between a slitting saw and a slotting cutter, consider the material thickness, desired slot width, and machine capabilities. Slitting saws excel in thin, precise cutting with minimal kerf, while slotting cutters are better for deeper slots and thicker materials. Evaluating cutting speed, tool rigidity, and application specifics ensures optimal tool selection for efficient machining.

Summary: Slitting Saw vs. Slotting Cutter Comparison

Slitting saws and slotting cutters serve distinct roles in precision machining, with slitting saws excelling in thin, high-speed cuts and slotting cutters optimized for deeper, more intricate slot profiles. Slitting saws typically feature a thin, circular blade ideal for cutting narrow slots, while slotting cutters possess multiple teeth designed for heavier material removal in slotting operations. Selecting between the two depends on specific machining requirements, including depth, precision, and material type.

Slitting saw vs slotting cutter Infographic

libmatt.com

libmatt.com