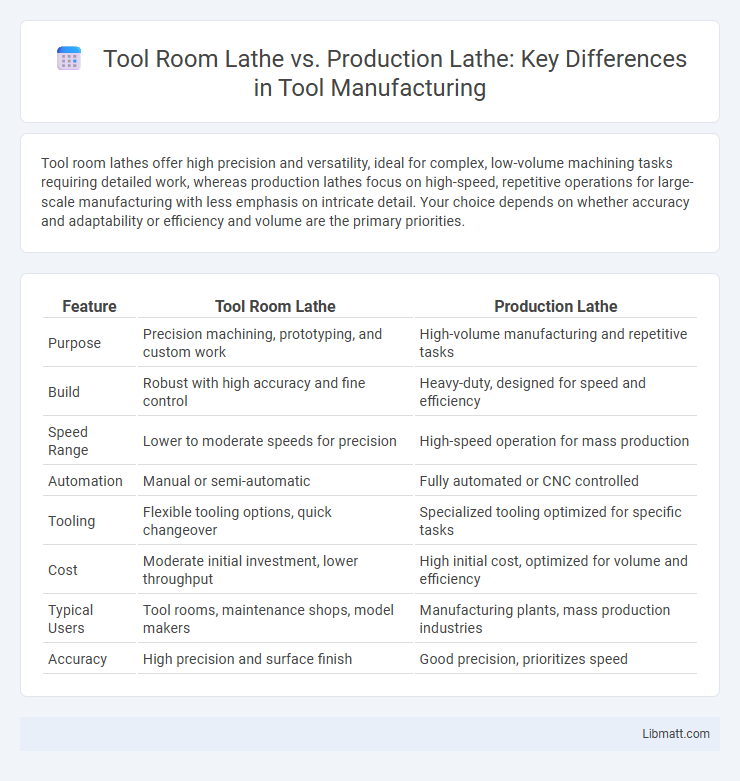

Tool room lathes offer high precision and versatility, ideal for complex, low-volume machining tasks requiring detailed work, whereas production lathes focus on high-speed, repetitive operations for large-scale manufacturing with less emphasis on intricate detail. Your choice depends on whether accuracy and adaptability or efficiency and volume are the primary priorities.

Table of Comparison

| Feature | Tool Room Lathe | Production Lathe |

|---|---|---|

| Purpose | Precision machining, prototyping, and custom work | High-volume manufacturing and repetitive tasks |

| Build | Robust with high accuracy and fine control | Heavy-duty, designed for speed and efficiency |

| Speed Range | Lower to moderate speeds for precision | High-speed operation for mass production |

| Automation | Manual or semi-automatic | Fully automated or CNC controlled |

| Tooling | Flexible tooling options, quick changeover | Specialized tooling optimized for specific tasks |

| Cost | Moderate initial investment, lower throughput | High initial cost, optimized for volume and efficiency |

| Typical Users | Tool rooms, maintenance shops, model makers | Manufacturing plants, mass production industries |

| Accuracy | High precision and surface finish | Good precision, prioritizes speed |

Introduction to Tool Room Lathe and Production Lathe

Tool room lathes are precision machines designed for small-scale, intricate work, ideal for creating prototypes and custom parts with high accuracy. Production lathes prioritize speed and efficiency, supporting large-scale manufacturing by handling repetitive tasks with less manual intervention. Choosing the right lathe depends on your need for precision versus volume in machining operations.

Key Differences in Design and Construction

Tool room lathes feature precision-ground ways, rigid construction, and high-quality spindle bearings designed for fine tolerance machining, whereas production lathes prioritize speed and volume with robust, heavy-duty frames and simplified components for repetitive tasks. Tool room lathes often include advanced features like micrometer-style dials and backlash compensation for detailed work, while production lathes focus on durability and ease of maintenance to maximize uptime. The design emphasis on accuracy and finish in tool room lathes contrasts with the emphasis on efficiency and throughput in production lathes.

Precision and Accuracy Comparison

Tool room lathes are engineered for superior precision and accuracy, featuring rigid construction, higher spindle speeds, and finer feed controls ideal for intricate, detailed work. Production lathes prioritize speed and volume with robust designs but typically offer less precision due to coarser feed mechanisms and reduced spindle accuracy. Consequently, tool room lathes excel in maintaining tight tolerances within microns, whereas production lathes focus on efficient mass production with acceptable dimensional variability.

Applications and Common Uses

Tool room lathes excel in precision machining, making them ideal for prototype development, intricate parts, and smaller batch production requiring tight tolerances. Production lathes are optimized for high-volume manufacturing, efficiently producing repetitive components in industries like automotive and aerospace. Your choice depends on whether you prioritize versatility and accuracy or speed and scalability in machining operations.

Speed and Production Capabilities

Tool room lathes operate at moderate speeds, offering precise control suited for prototype and small-batch work, while production lathes are designed for high-speed operation to maximize output in mass production environments. Production lathes feature advanced automation and higher horsepower motors that enable continuous, efficient machining of large volumes with consistent quality. Speed and production capabilities in production lathes surpass those of tool room lathes, making them essential for industries demanding large-scale manufacturing throughput.

Tooling and Setup Time

Tool room lathes are equipped with precision tooling that allows for intricate and custom machining, but this often results in longer setup times due to the need for meticulous adjustments and alignment. Production lathes utilize standardized, interchangeable tooling designed for high-volume runs, significantly reducing setup time and increasing overall efficiency. Your manufacturing process benefits from choosing a production lathe when quick changeovers and repeatability are crucial, while a tool room lathe excels in flexibility for complex, low-volume parts.

Flexibility and Versatility

Tool room lathes offer superior flexibility and versatility through their precision controls and ability to handle intricate, custom machining tasks, making them ideal for prototype development and small batch production. Production lathes prioritize high-speed operation and repeatability for mass manufacturing, but often lack the adaptability for complex or varied workpieces. The enhanced tooling options and precise adjustments available in tool room lathes allow for a broader range of materials and cutting operations compared to the typically fixed setup of production lathes.

Cost and Investment Considerations

Tool room lathes typically require a higher initial investment due to their precision engineering and versatility, making them ideal for small-scale, high-accuracy projects. Production lathes, in contrast, focus on cost efficiency and high-volume output, offering lower per-unit costs despite a larger total investment for mass manufacturing. Your choice depends on balancing upfront costs against long-term production needs and volume requirements.

Maintenance and Durability

Tool room lathes demand meticulous maintenance to ensure precision and longevity, as they are engineered for fine, detailed work requiring tight tolerances. Production lathes emphasize durability and robust construction to withstand high-volume, repetitive tasks with less frequent maintenance intervals. Understanding your workload's intensity helps determine whether the superior maintenance of a tool room lathe or the rugged durability of a production lathe better suits your needs.

Choosing the Right Lathe for Your Workshop

Tool room lathes offer high precision and versatility, ideal for intricate tasks and prototype development, making them essential for specialized workshops. Production lathes prioritize speed and durability, designed for high-volume manufacturing and repetitive operations to maximize output. Choosing the right lathe depends on your workshop's focus--opt for a tool room lathe for precision machining or a production lathe to enhance efficiency in mass production.

Tool room lathe vs production lathe Infographic

libmatt.com

libmatt.com