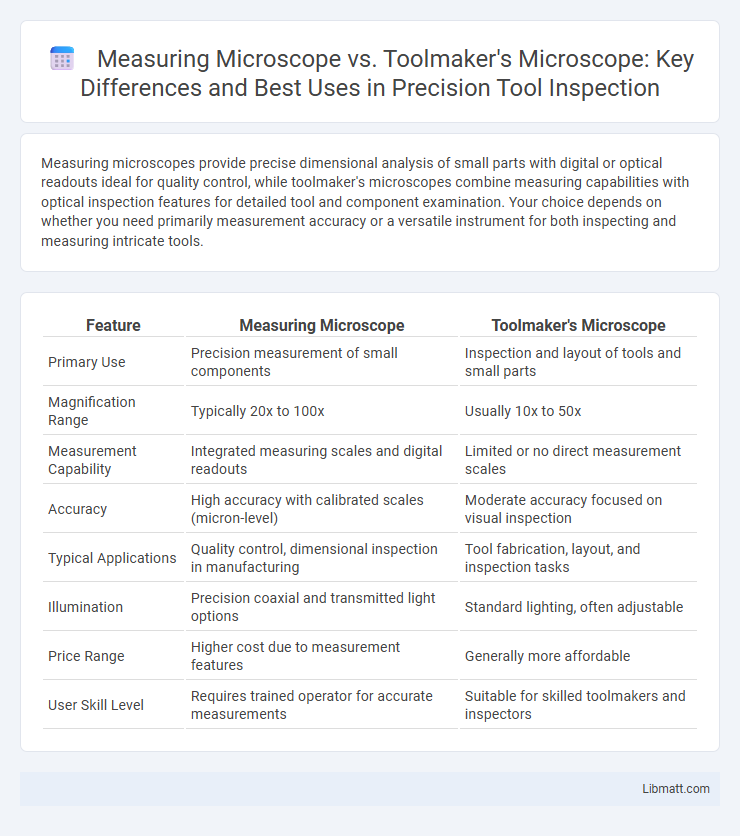

Measuring microscopes provide precise dimensional analysis of small parts with digital or optical readouts ideal for quality control, while toolmaker's microscopes combine measuring capabilities with optical inspection features for detailed tool and component examination. Your choice depends on whether you need primarily measurement accuracy or a versatile instrument for both inspecting and measuring intricate tools.

Table of Comparison

| Feature | Measuring Microscope | Toolmaker's Microscope |

|---|---|---|

| Primary Use | Precision measurement of small components | Inspection and layout of tools and small parts |

| Magnification Range | Typically 20x to 100x | Usually 10x to 50x |

| Measurement Capability | Integrated measuring scales and digital readouts | Limited or no direct measurement scales |

| Accuracy | High accuracy with calibrated scales (micron-level) | Moderate accuracy focused on visual inspection |

| Typical Applications | Quality control, dimensional inspection in manufacturing | Tool fabrication, layout, and inspection tasks |

| Illumination | Precision coaxial and transmitted light options | Standard lighting, often adjustable |

| Price Range | Higher cost due to measurement features | Generally more affordable |

| User Skill Level | Requires trained operator for accurate measurements | Suitable for skilled toolmakers and inspectors |

Introduction to Measuring Microscopes and Toolmaker’s Microscopes

Measuring microscopes are precision optical instruments designed to measure small components with high accuracy using graduated scales and digital readouts. Toolmaker's microscopes combine magnification with precise movement controls, enabling detailed inspection and measurement of tool geometry and workpiece dimensions. Both microscopes serve critical roles in manufacturing and quality control by providing enhanced accuracy for dimensional analysis and inspection of intricate parts.

Key Features of Measuring Microscopes

Measuring microscopes feature calibrated scales and digital readouts for precise dimensional analysis of small parts, offering high magnification with adjustable illumination for enhanced visibility. They often include micrometer heads or digital encoders to measure lengths, angles, and depths accurately, suitable for quality control and inspection tasks in manufacturing. These devices provide stable mounting and fine focusing capabilities, enabling repeatable measurements with minimal operator error.

Essential Characteristics of Toolmaker’s Microscopes

Toolmaker's microscopes are designed with high precision optics and a rigid, stable frame to ensure accurate measurement of small parts and intricate details. They feature graduated scales, micrometer heads, and fine focusing mechanisms that enable precise dimensional inspections essential for quality control in manufacturing. Your ability to measure complex geometries and verify tolerances is enhanced by the toolmaker's microscope's superior magnification and measurement accuracy compared to a standard measuring microscope.

Optical Systems: Measuring Microscope vs Toolmaker’s Microscope

Measuring microscopes utilize precision optical systems with higher magnification and calibrated reticles designed for dimensional measurement accuracy, enabling detailed inspection of small components. Toolmaker's microscopes feature versatile optical systems optimized for layout work, allowing users to view and mark tool patterns with less emphasis on measurement precision. Your choice depends on whether you require exact quantitative analysis or qualitative layout inspection in your application.

Measurement Accuracy and Precision Comparison

Measuring microscopes offer high measurement accuracy and precision through integrated micrometer scales and digital readouts, enabling precise dimensional analysis of small parts. Toolmaker's microscopes provide exceptional precision for layout work and inspection with fine optical clarity and adjustable measurement scales, but may require more manual calibration for exact accuracy. Your choice depends on whether automated digital accuracy or manual precision with flexibility better suits your measurement requirements.

Typical Applications in Industry and Research

Measuring microscopes are widely used in precision engineering and quality control for inspecting small mechanical parts and verifying dimensional accuracy in manufacturing. Toolmaker's microscopes serve critical roles in tool design, maintenance, and inspection, particularly in mold making, die sinking, and fine measurement of intricate components. Both instruments enable high-precision measurement, but measuring microscopes are favored for general dimensional analysis, while toolmaker's microscopes specialize in detailed tool inspection and layout tasks.

Stage Movement and Coordinate Measurement Capabilities

Measuring microscopes feature precise stage movement with micrometer adjustments that enable accurate measurement of small components, often incorporating digital readouts for enhanced coordinate tracking. Toolmaker's microscopes provide highly sensitive, finely graduated coordinate measurement capabilities, allowing for detailed inspection and layout of tools and dies with exceptional repeatability. Both types utilize calibrated stage movements but differ in application scope, with toolmaker's microscopes offering superior accuracy for complex dimensional analysis.

Ease of Use and User Interface Differences

Measuring microscopes feature digital displays and intuitive controls designed for rapid dimension readings, enhancing ease of use for operators in quality control environments. Toolmaker's microscopes rely on manual adjustments and vernier scales, requiring skilled operators to interpret measurements precisely. The digital interface of measuring microscopes reduces user error and speeds up data acquisition compared to the analog user interface of traditional toolmaker's microscopes.

Pricing and Cost-effectiveness Analysis

Measuring microscopes generally offer more affordable pricing and are cost-effective for standard dimensional inspections, whereas toolmaker's microscopes tend to be more expensive due to advanced features and higher precision capabilities suitable for detailed tool and die work. The initial investment in toolmaker's microscopes is justified when high-accuracy measurements and versatility in complex geometries are required, providing better long-term value despite higher upfront costs. For budget-conscious applications centered on routine measurements, measuring microscopes deliver sufficient accuracy with lower operational expenses.

Choosing the Right Microscope for Your Application

Measuring microscopes offer precise dimensional analysis with digital readouts, ideal for quality control in manufacturing, while toolmaker's microscopes provide versatile visual inspection and layout capabilities for intricate tooling and assembly tasks. Your choice depends on whether you prioritize high-accuracy measurements or flexible part examination and alignment. Selecting the right microscope ensures optimal efficiency and accuracy tailored to your specific application needs.

Measuring microscope vs toolmaker’s microscope Infographic

libmatt.com

libmatt.com